Cooking device and steam valve assembly thereof

A technology of cooking utensils and steam valves, applied in the field of kitchen appliances, can solve the problems of unguaranteed sealing effect, failure to achieve sealing effect, continuous air leakage, etc., achieve the effect of improving cooking effect or fresh-keeping effect, simple structure, and ensuring smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

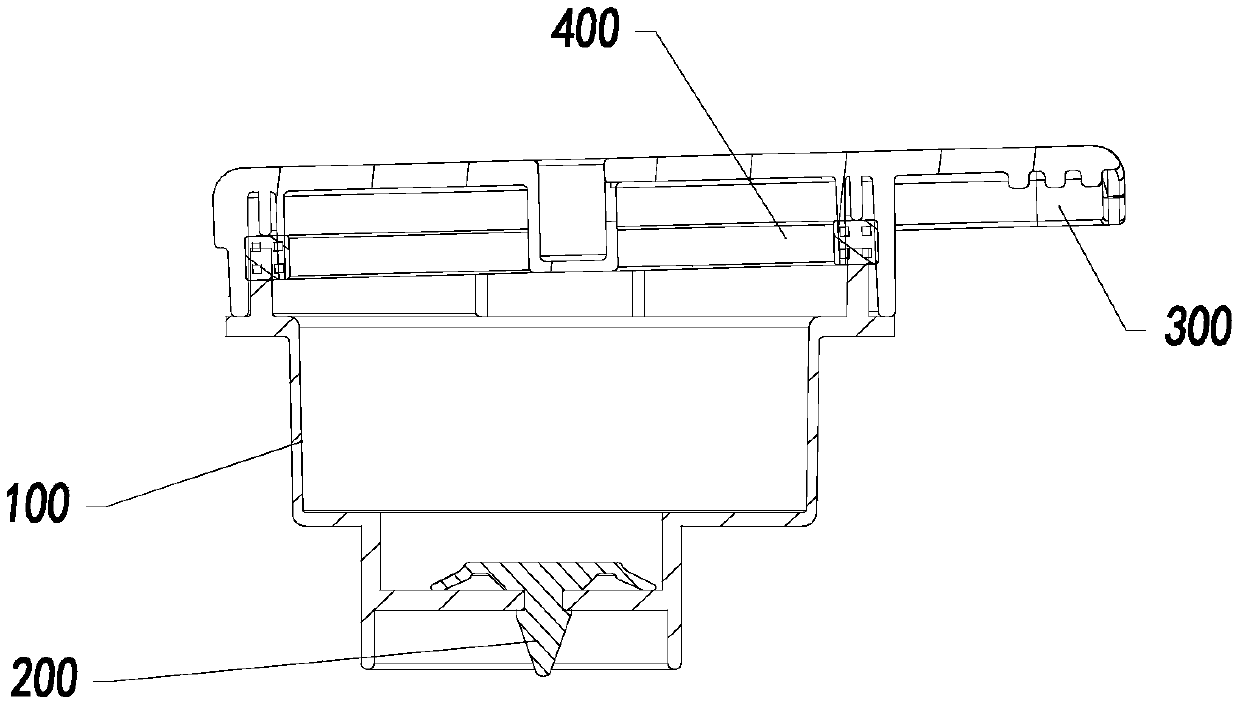

[0044] refer to figure 1 , 2 , the steam valve assembly proposed in Embodiment 1 of the present invention includes a valve body 100 and a sealing device 200 , the valve body 100 is provided with a bonnet 300 , a sealing ring 400 is provided between the bonnet 300 and the valve body 100 , and the valve body 100 is A steam hole 110 is opened, and the sealing device 200 is used for sealing the steam hole 110 . The steam hole 110 of the steam valve assembly is used to release pressure and exhaust steam to the outside. During the cooking process, the internal pressure of the cooking utensil can be released.

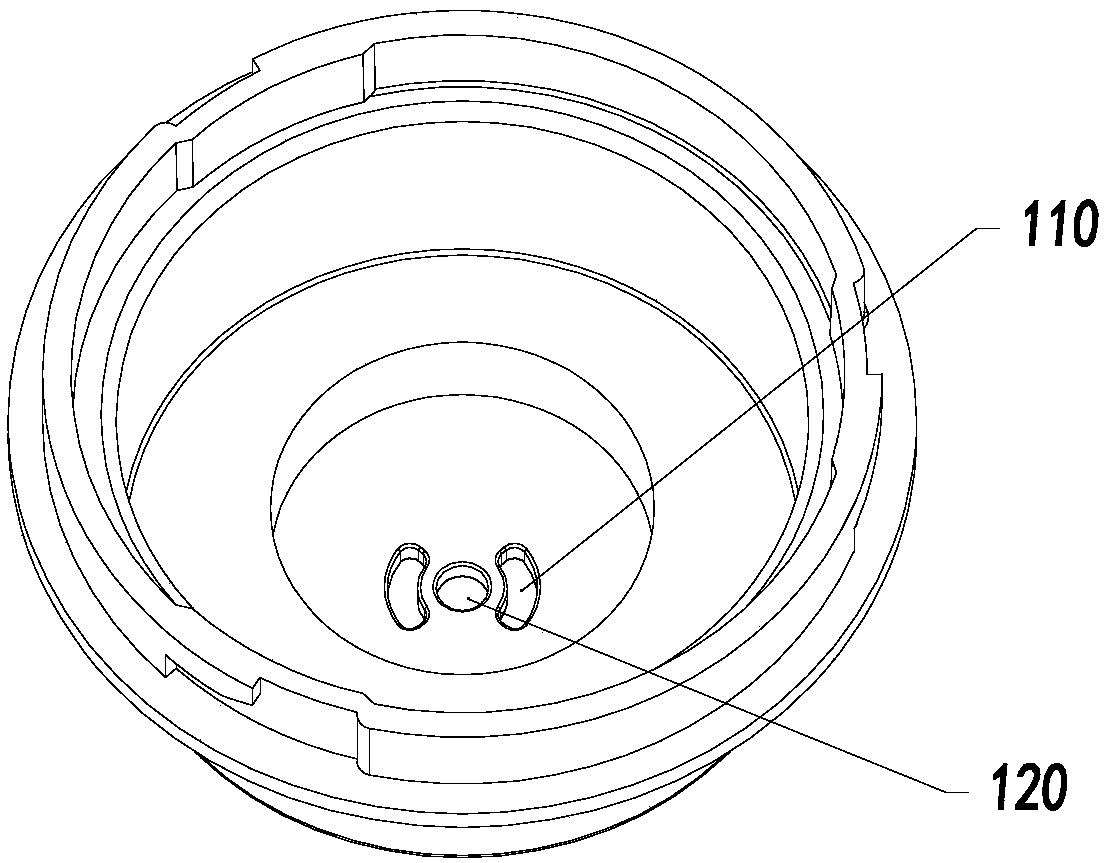

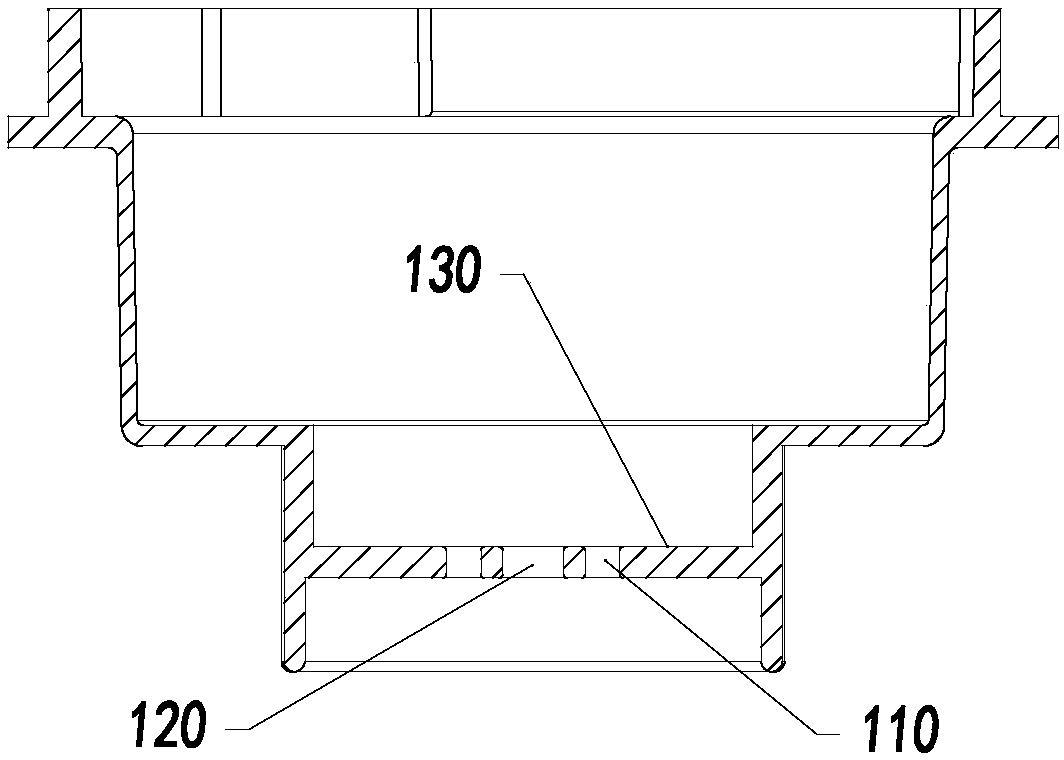

[0045] like figure 2 and 3 As shown, a steam hole 110 is opened at the bottom of the valve body 100 in this embodiment. When the sealing device 200 is not provided, the steam hole 110 communicates with the steam channel inside the valve body 100 . One or more steam holes 110 at the bottom of the valve body 100 can be provided. In this embodiment, two steam holes 110 are p...

Embodiment 2

[0058] This implementation proposes a steam valve sealing device, and the sealing device proposed in this embodiment can be applied to the steam valve assembly proposed in Embodiment 1;

[0059] like Figure 7 and 8 As shown, the sealing device 200 of this embodiment includes a sealing body 210, a sealing lip 220 is disposed on one side of the sealing body 210 in the circumferential direction, and a sealing mating surface with the valve body 100 is provided on the lower side of the sealing body 210. 130 fits the installation mating surface 211, the plane where the free end 223 of the sealing lip 220 is located is lower than the plane where the installation mating surface 211 is located; the installed installation mating surface 211 will cooperate with the sealing mating surface 130 after installation, Since the plane where the free end 223 is located is lower than the plane where the installation mating surface 211 is located, the sealing lip 220 will be in a sealed state aft...

Embodiment 3

[0073] like Figure 9 As shown, this embodiment proposes a cooking appliance, including the steam valve assembly 010 and the sealing device 200 as described in Embodiment 1 and Embodiment 2. This cooking appliance can be one of an electric rice cooker or an electric pressure cooker, specifically Including the pot body 012 and the upper cover 014, the upper cover 014 is closed on the pot body 012, the inner tank 013 is placed on the pot body 012, and the upper cover 014 is provided with a vacuum device 015 for vacuuming the inner tank , to achieve accelerated water absorption and preservation functions.

[0074] The pot cover is also provided with a steam valve assembly 010, and the steam valve assembly 010 is provided with a sealing device 200, through which the sealing device 200 can be used to prevent the steam valve assembly from entering the air, and when it is necessary to exhaust steam and pressure during cooking, The steam valve can be connected for exhaust and pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com