Glue dispenser, piezoelectric injection valve and quick assembling and disassembling flow channel device thereof

A technology of piezoelectric injection and flow channel, which is applied in the direction of valve device, valve operation/release device, device for coating liquid on the surface, etc. It can solve the problems of cumbersome disassembly and assembly, time-consuming, etc., and achieve convenient and quick operation and prevent vibration , The effect of simplifying the maintenance process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

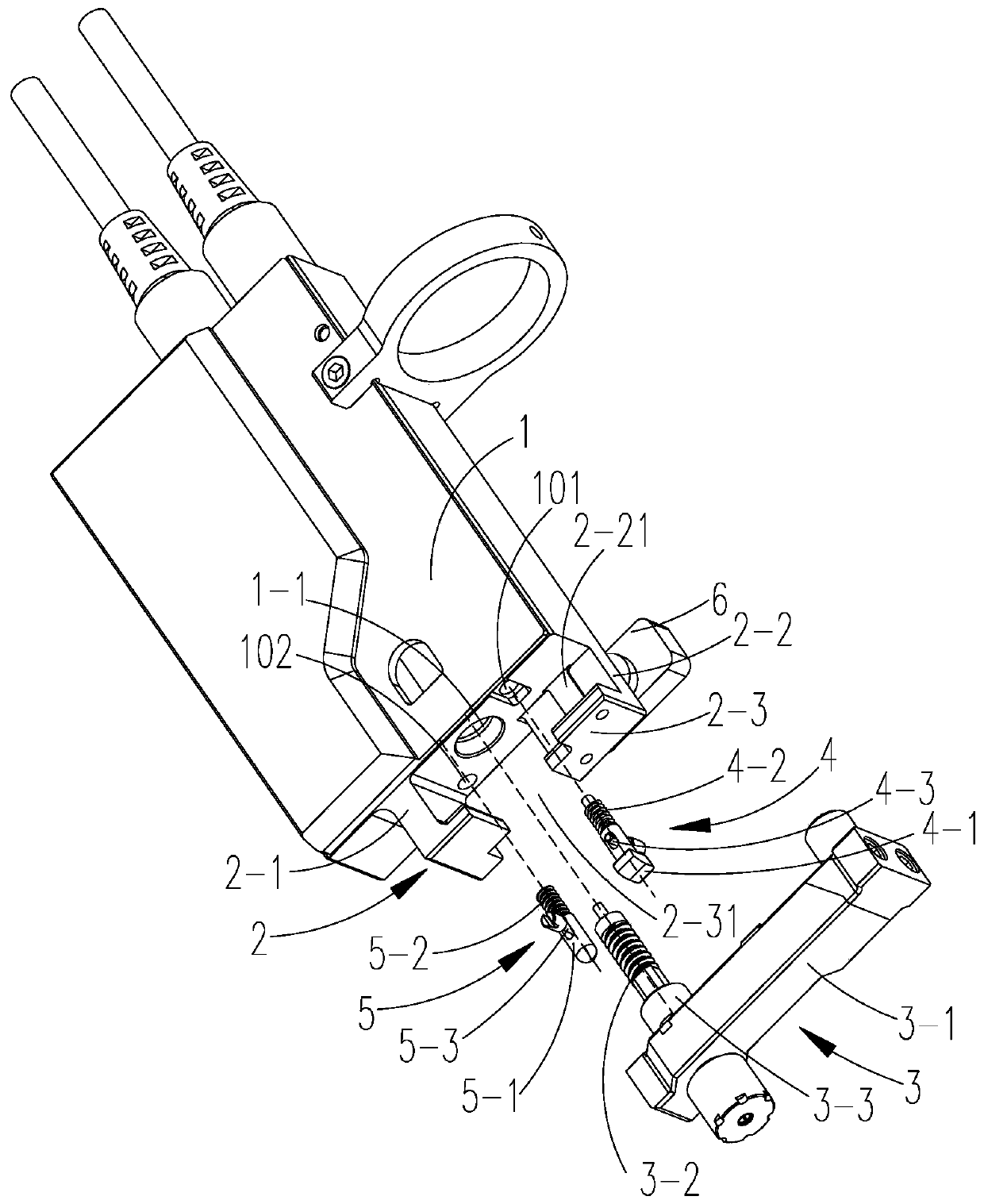

[0055] Such as Figure 1-11 As shown, a quick loading and unloading flow channel device is used for piezoelectric injection valves. The piezoelectric injection valves include a valve body 1, a mounting part 2 at the bottom of the valve body 1 and a push rod installation hole 1-1. The flow channel Devices include:

[0056] The flow channel assembly 3 has a flow channel body 3-1 and an injection push rod 3-2 arranged on the flow channel body 3-1. The installation part 2 of the valve body 1 is provided with a flow channel body 3-1 The loading position 7 of the installation part 2 and the working position 8 where the flow channel body 3-1 is working. When the flow channel body 3-1 is inserted into the loading position 7, the injection push rod 3-2 will also be located In the push rod installation hole 1-1; wherein, the runner body 3-1 can rotate along the installation direction and the disassembly direction opposite to the installation direction with the axis of the injection pus...

Embodiment 2

[0083] The difference between embodiment 2 and embodiment 1 is that the locking units used are different, as follows:

[0084] Such as Figure 12 As shown, the locking unit includes a main preload assembly 4, the main preload assembly 4 has an elastically retractable compression block 4-1, and the runner body 3-1 is installed from the loading position 7 along the When the direction is rotated to the working position 8, the flow channel body 3-1 will overcome the elasticity on the compression block 4-1 to force the compression block 4-1 to displace, and after the flow channel body 3-1 reaches the working position 8, it will convect the flow channel. The body 3 - 1 generates a certain pre-tightening force to press it against the installation part 2 .

[0085] One end of the compression block 4-1 in the main preload assembly 4 is fixed on the valve body 1, and the other end is tilted towards the flow channel body 3-1 at the working position 8; thus, the compression block 4-1 its...

Embodiment 3

[0098] The difference between embodiment 3 and implementation 2 or 3 is that the locking units used are different, as follows:

[0099] Such as Figure 13 As shown, the locking unit includes a locking screw 6 arranged on the mounting part 2, the upper surface of the flow channel body 3-1 at the working position 8 is in contact with the bottom surface of the valve body 1, and the flow channel at the working position 8 The lower surface of the body 3-1 is in contact with the installation part 2, and the locking screw 6 is screwed to the flow channel body 3-1 at the working position 8.

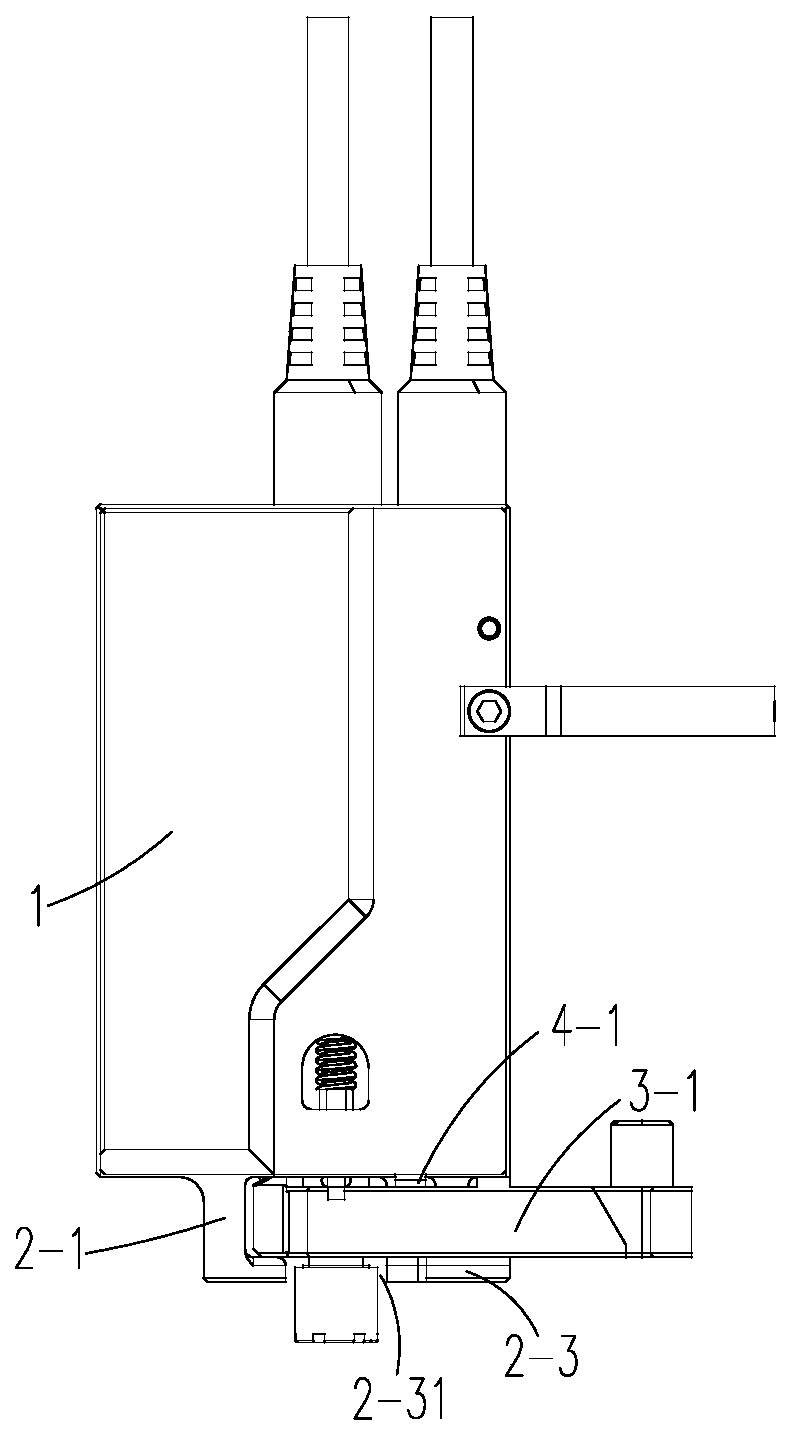

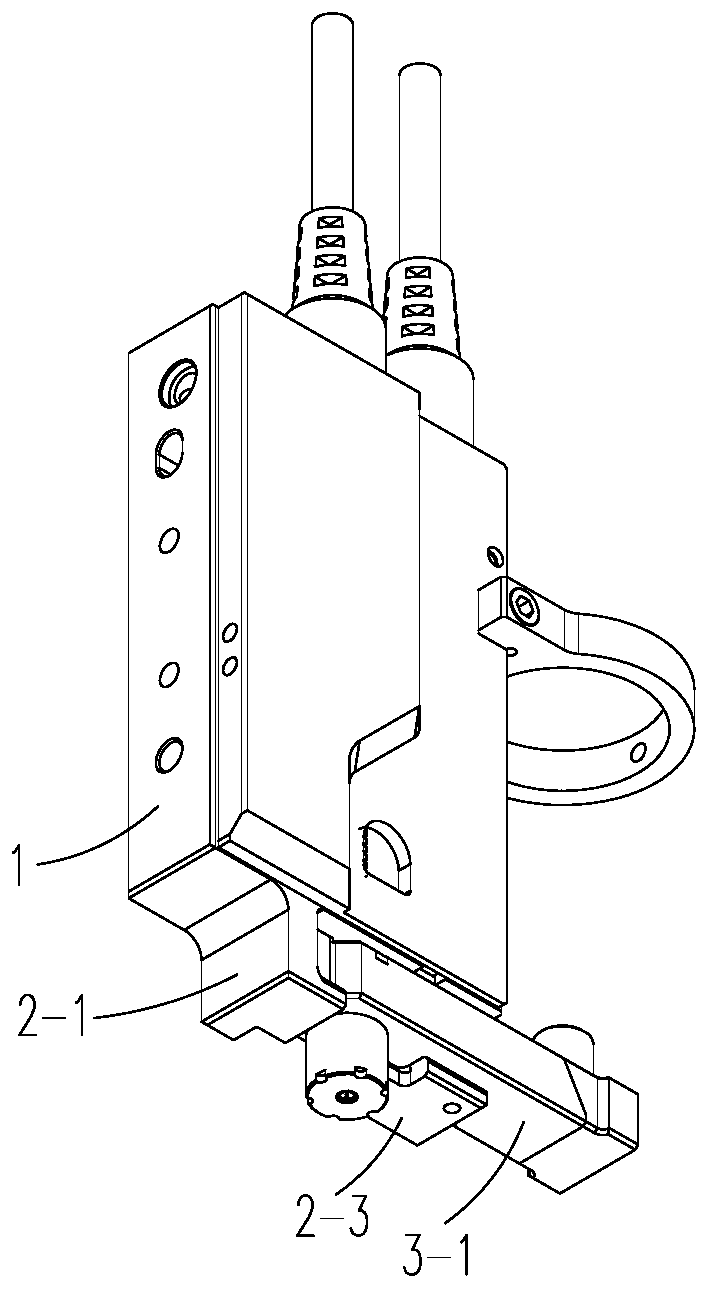

[0100] Such as figure 2 , 3 As shown in and 13, the installation part 2 includes a right side plate 2-1 fixed on the right side of the bottom surface of the valve body 1, a rear side plate 2-2 fixed on the rear side of the bottom surface of the valve body 1, and relatively fixed on the right side plate 2. -1 and the bottom side plate 2-3 at the bottom of the rear side plate 2-2, the flow chan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap