Rolling device for colored tape production

A technology of winding device and ribbon, which is applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problem that the device body cannot work, affects the working efficiency of the winding device, and replaces the coil of the winding ribbon cylinder trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

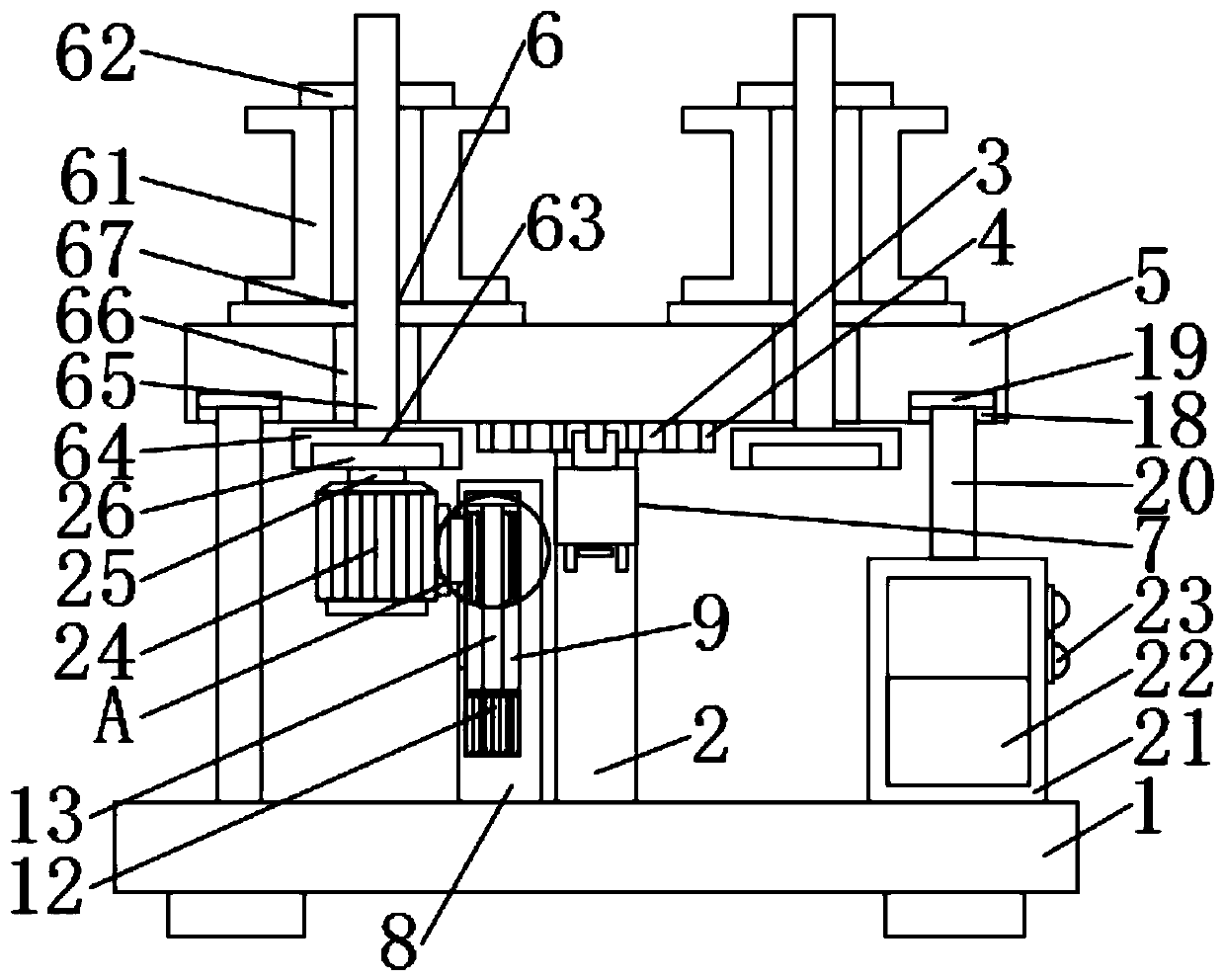

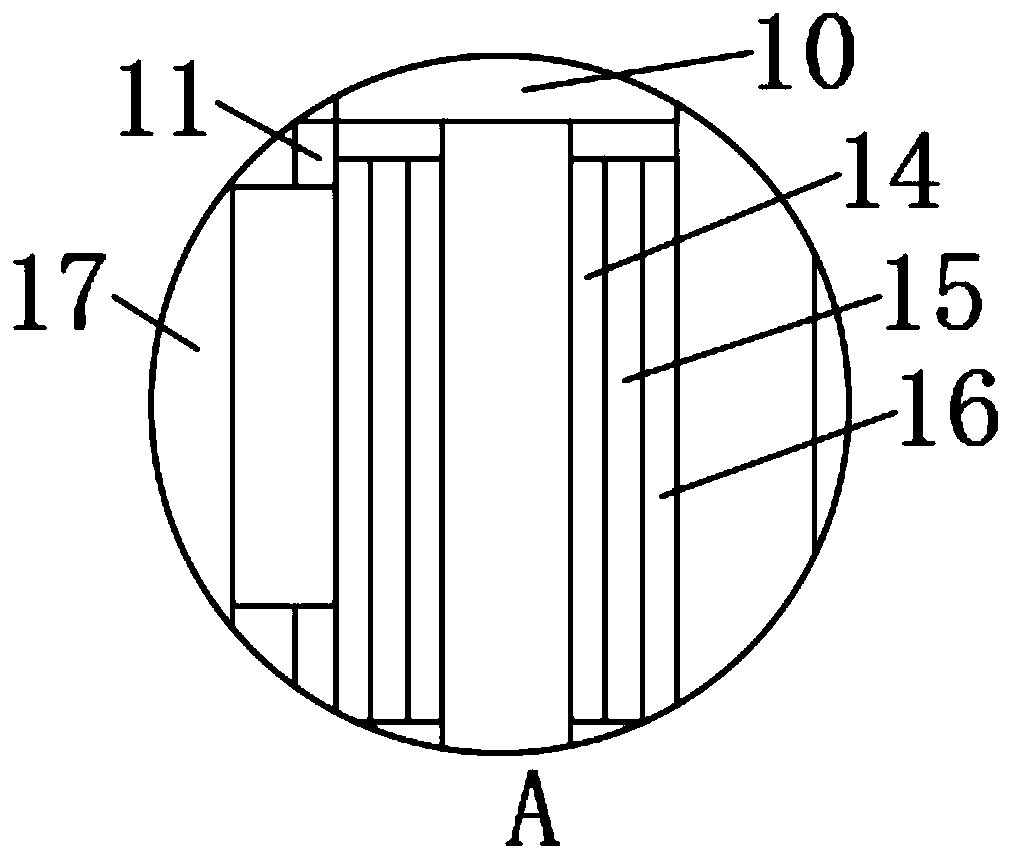

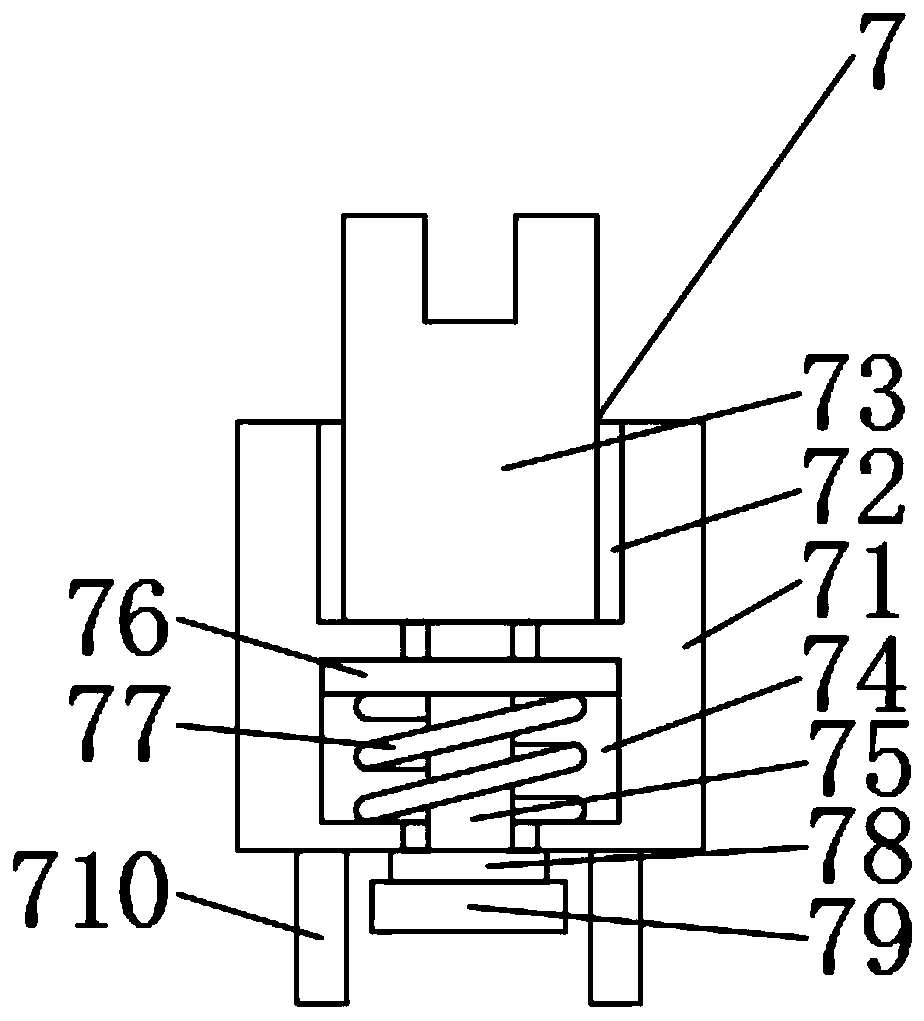

[0026] like Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a winding device for ribbon production, including a fixed seat 1, the middle part of the upper end of the fixed seat 1 is fixedly connected with a support column 2, and the upper end of the support column 2 rotates A first rotating disk 3 is connected, and a plurality of blocks 4 are fixedly connected to the periphery of the first rotating disk 3. The distance between two adjacent blocks 4 is the same. The upper end of the first rotating disk 3 A turntable 5 is fixedly connected, both sides of the turntable 5 are fixedly connected with a winding mechanism 6, the front upper end of the support column 2 is fixedly connected with a limit mechanism 7, and one side of the upper end of the fixed seat 1 is fixedly connected with a vertical plate 8, the inside of the vertical plate 8 is provided with a second cavity 9, the inner upper end of the second cavity 9 is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com