Nanometer material ejection acceleration method

A technology of nano-materials and carbon nano-cones, which is applied in the field of nano-material ejection acceleration and nano-processing, can solve the problems of difficult control of the ejection speed of objects to be accelerated and complex preparation methods of accelerators, etc., to achieve convenient determination of compression amount, easy speed control, easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

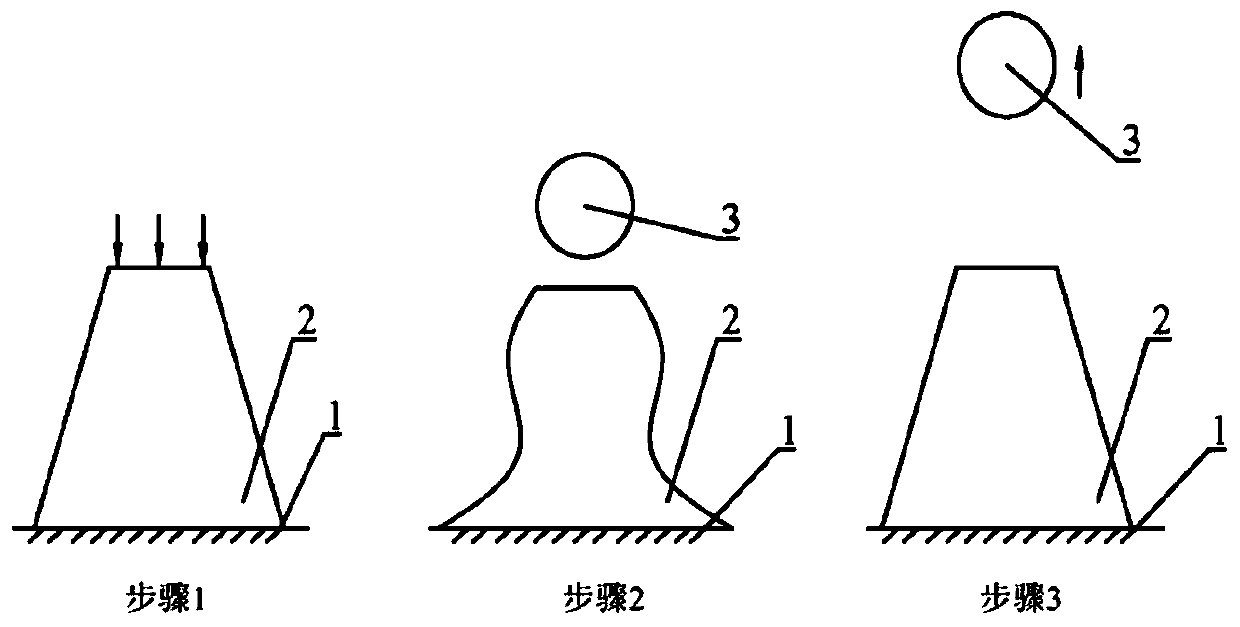

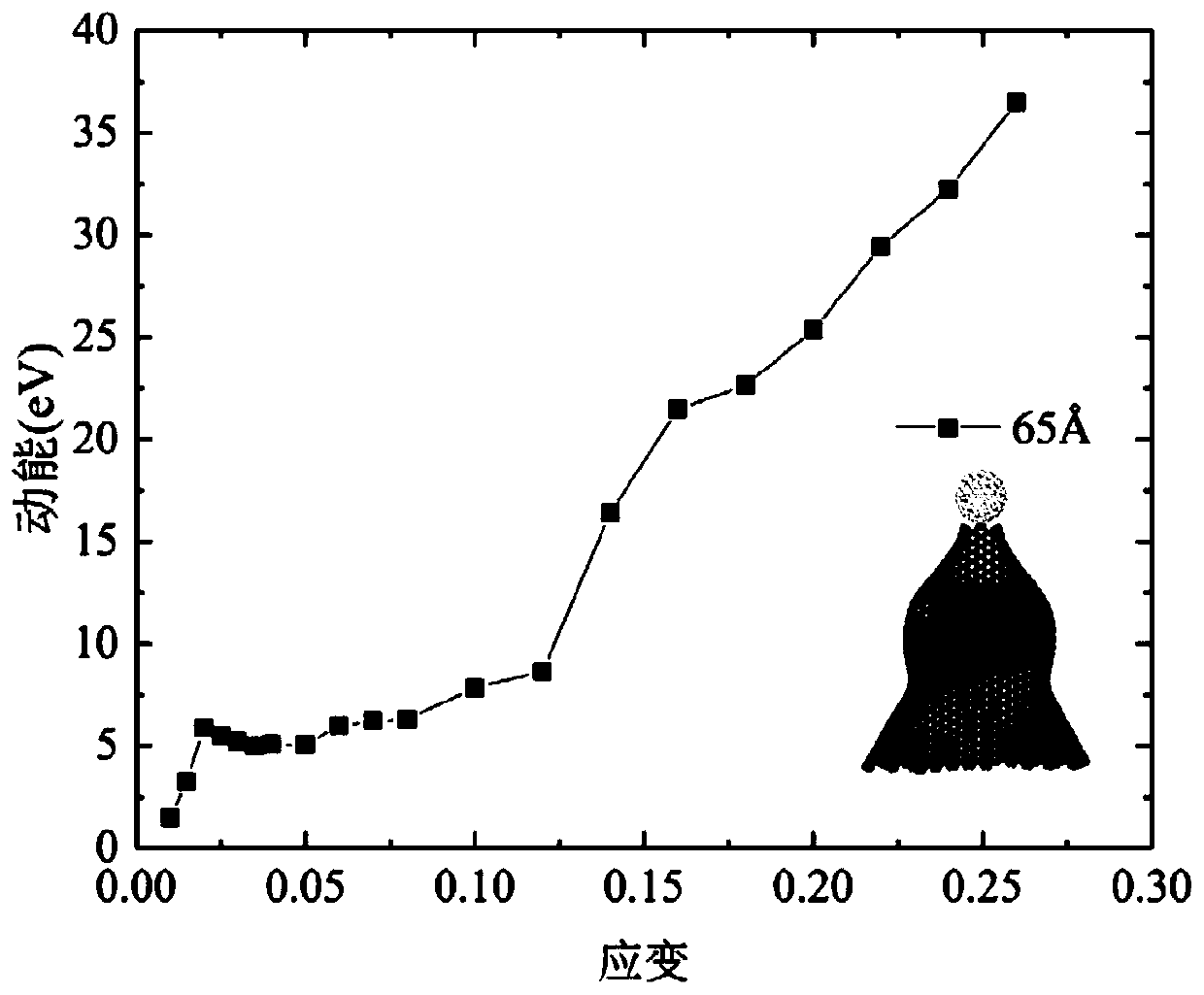

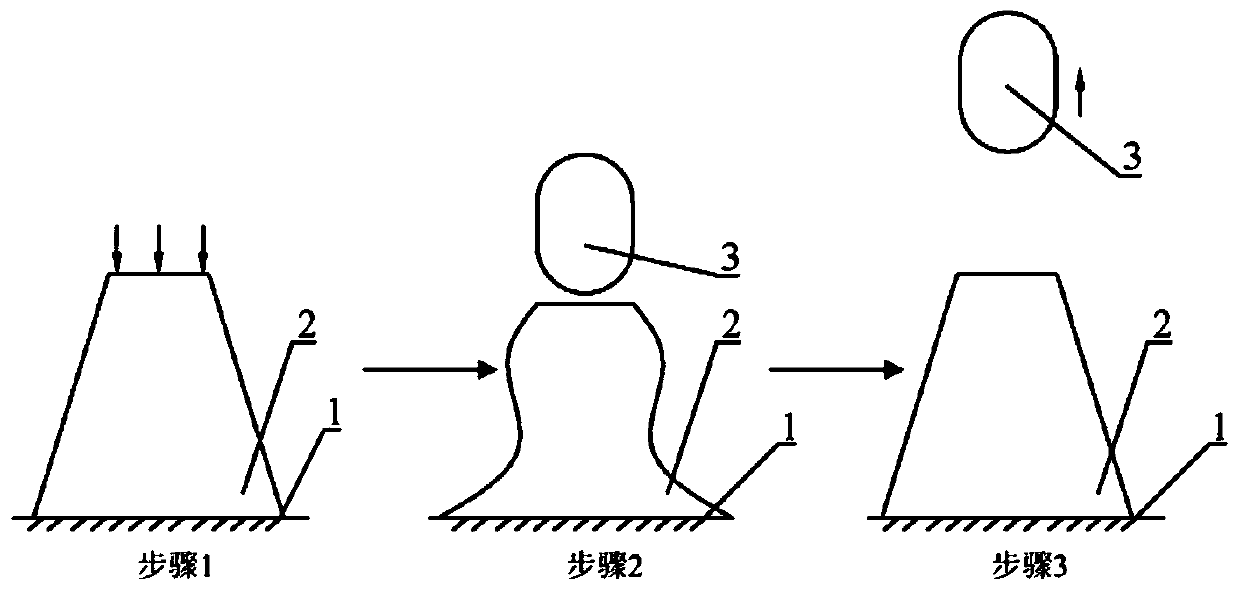

[0031] figure 1 The included angle between the generatrix of the shown open carbon nanocone 2 and the bottom surface is 70.55°, and the height is The upper opening radius is The object to be accelerated is fullerene C180. The compression process of this open carbon nanocone and the rebound fullerene C180 process are carried out based on the molecular dynamics simulation of Lammps software (Lammps is a commonly used open source simulation software, see https: / / lammps.sandia.gov / ), and finally obtain the relationship between the kinetic energy of fullerene C180 and the strain of the open carbon nanocone, the result is as figure 2 shown.

[0032] When the speed of fullerene C180 is accelerated to 500m / s, its kinetic energy is 3.41eV, and the speed can be realized in the linear elastic stage of the open carbon nanocone. The specific implementation includes three steps:

[0033] Step 1: First, set the angle between the bus bar and the bottom surface to be 70.55°...

Embodiment 2

[0038] When it is necessary to accelerate the speed of fullerene C180 to 1400m / s, by figure 2 It can be seen that this accelerated process can be realized in the buckling stage of the open carbon nano cone (consistent with embodiment 1), and the specific implementation includes three steps:

[0039] Step 1: The kinetic energy needed to accelerate the speed of fullerene C180 to 1400m / s is about 21.60eV, then according to figure 2 It can be determined that when the strain of the open carbon nanocone is 0.16, the corresponding kinetic energy converted is about 21.60eV, so an external pressure is applied to the top of the open carbon nanocone, and the open carbon nanocone 2 is compressed to a strain of 0.16;

[0040] Step 2: Place the fullerene C180 above the compressed open carbon nanocone 2, and keep the distance between the bottom of the fullerene C180 and the upper bottom surface of the open carbon nanocone at

[0041] Step 3: release the compressed open carbon nanoco...

Embodiment 3

[0043] When the speed of fullerene C180 needs to be accelerated to 1800m / s, by figure 2 It can be seen that the compression of the open carbon nano cone (consistent with embodiment 1) can be realized near the extreme, and the specific implementation includes three steps:

[0044] Step 1: The kinetic energy needed to accelerate the speed of fullerene C180 to 1800m / s is about 36.64eV, then according to figure 2 It can be determined that the required strain of the open carbon nanocone is 0.26, so an external pressure is applied to the top of the open carbon nanocone to compress the open carbon nanocone 2 to a strain of 0.26;

[0045] Step 2: Place the fullerene C180 above the compressed open carbon nanocone 2, and keep the distance between the bottom of the fullerene C180 and the upper bottom surface of the open carbon nanocone at

[0046] Step 3: release the compressed open carbon nanocone 2, and the open carbon nanocone 2 instantly recovers its deformation, and part of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap