Combined type fire grate incinerator primary air feeding device

A technology of air supply device and incinerator, which is applied in the direction of combustion air/fuel supply, incinerator, combustion method, etc. It can solve the problems of uneven stirring of garbage and insufficient combustion, and achieve the effect of shortening the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

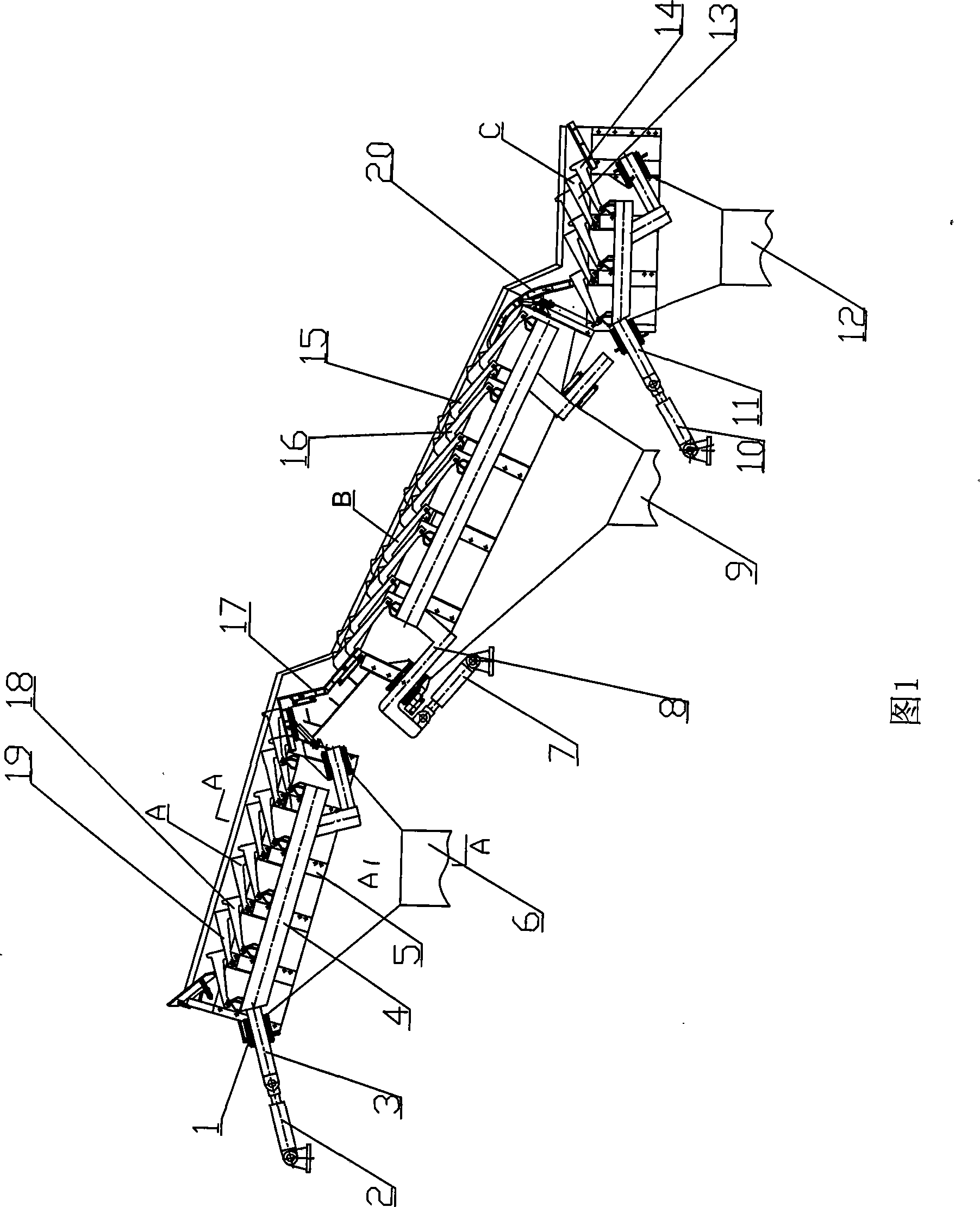

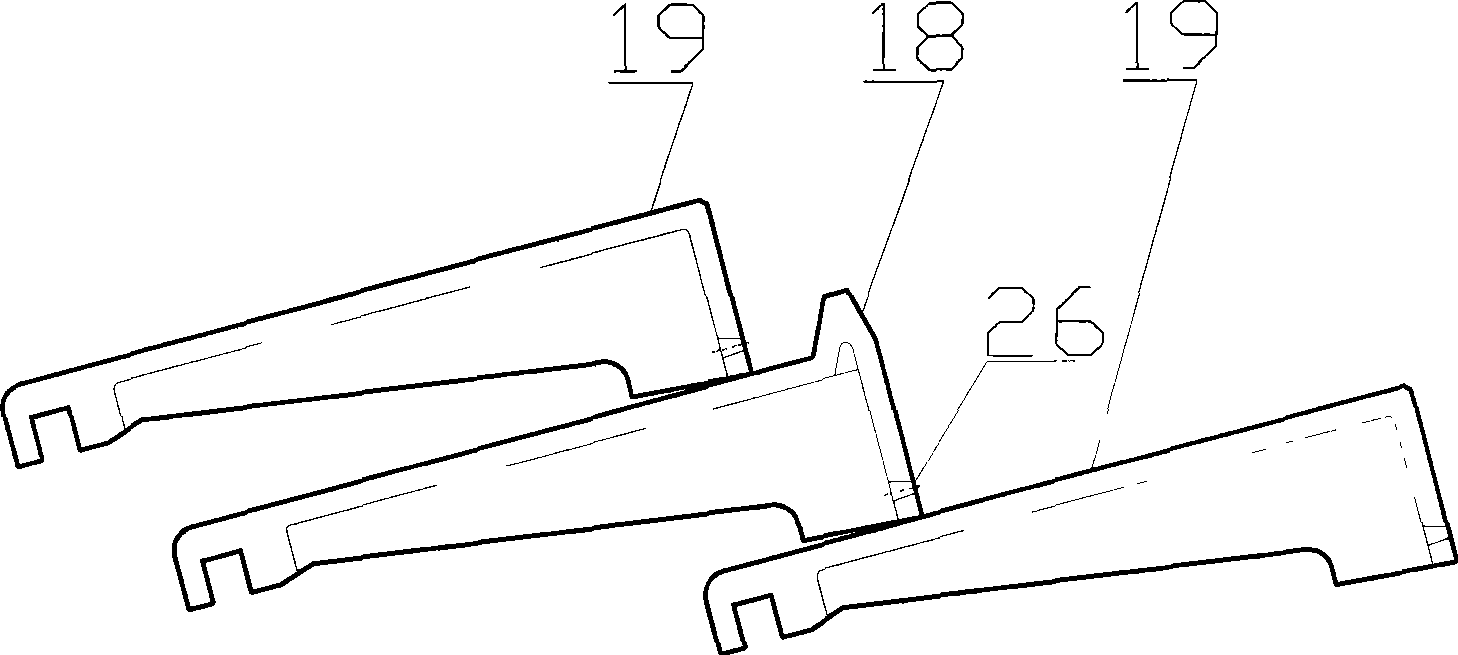

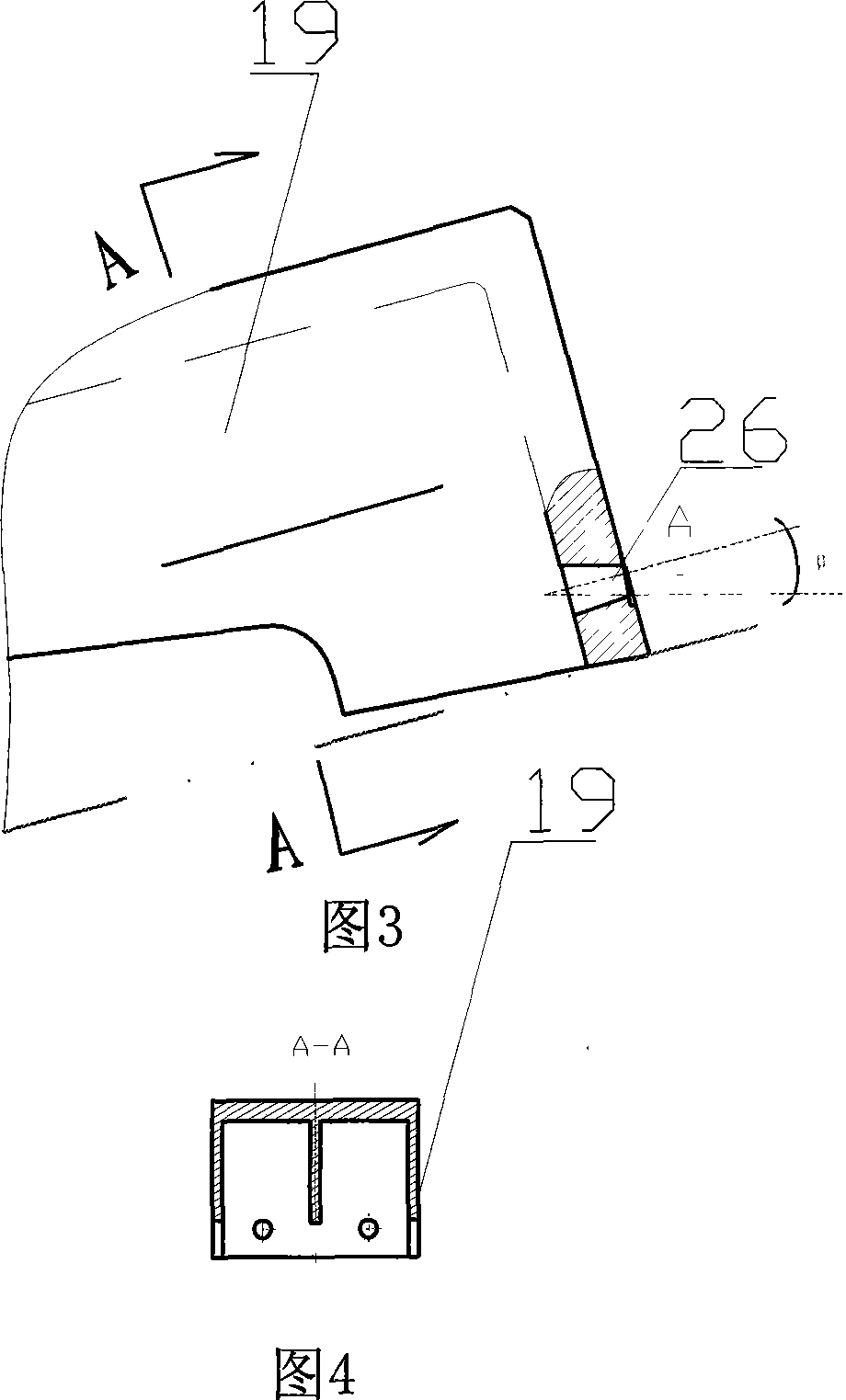

[0032] please see figure 1 , Figure 5 , Figure 7 , a composite grate incinerator primary air supply device, the movable grate pieces 14, 16, 18 and the fixed grate pieces 13, 15, 19 are overlapped and connected to form a sloped grate, and the movable grate pieces 14 , 16, 18 and the fixed grate pieces 13, 15, 19 are provided with an air outlet 26, and the movable grate pieces 14, 16, 18 are clamped on the crossbeam 21 through the draw-in groove at the tail, and the two ends of the crossbeam 21 are lapped on the pull rod 4 On the top, the fixed grate pieces 13, 15, 19 are clamped on the fixed column 5 through the slots at the tail; the grate is divided into a drying section A, a burning section B, and a burning section C, and there is a height difference between each section. Wherein the drying section A is the highest point, the burning section C is the lowest point, and the burning section B is located between the drying section A and the burning section C; the drying sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com