Column base joint for modular building

A column foot joint and modular technology, which is applied to buildings, columns, piers, etc., can solve the problems of inconvenient disassembly and assembly of column foot joints and poor shear resistance, and achieve the effect of improving shear resistance and quick disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] From the above content, it can be seen that the modular building can quickly complete the construction and construction, save labor costs, and also has the characteristics of green and environmental protection.

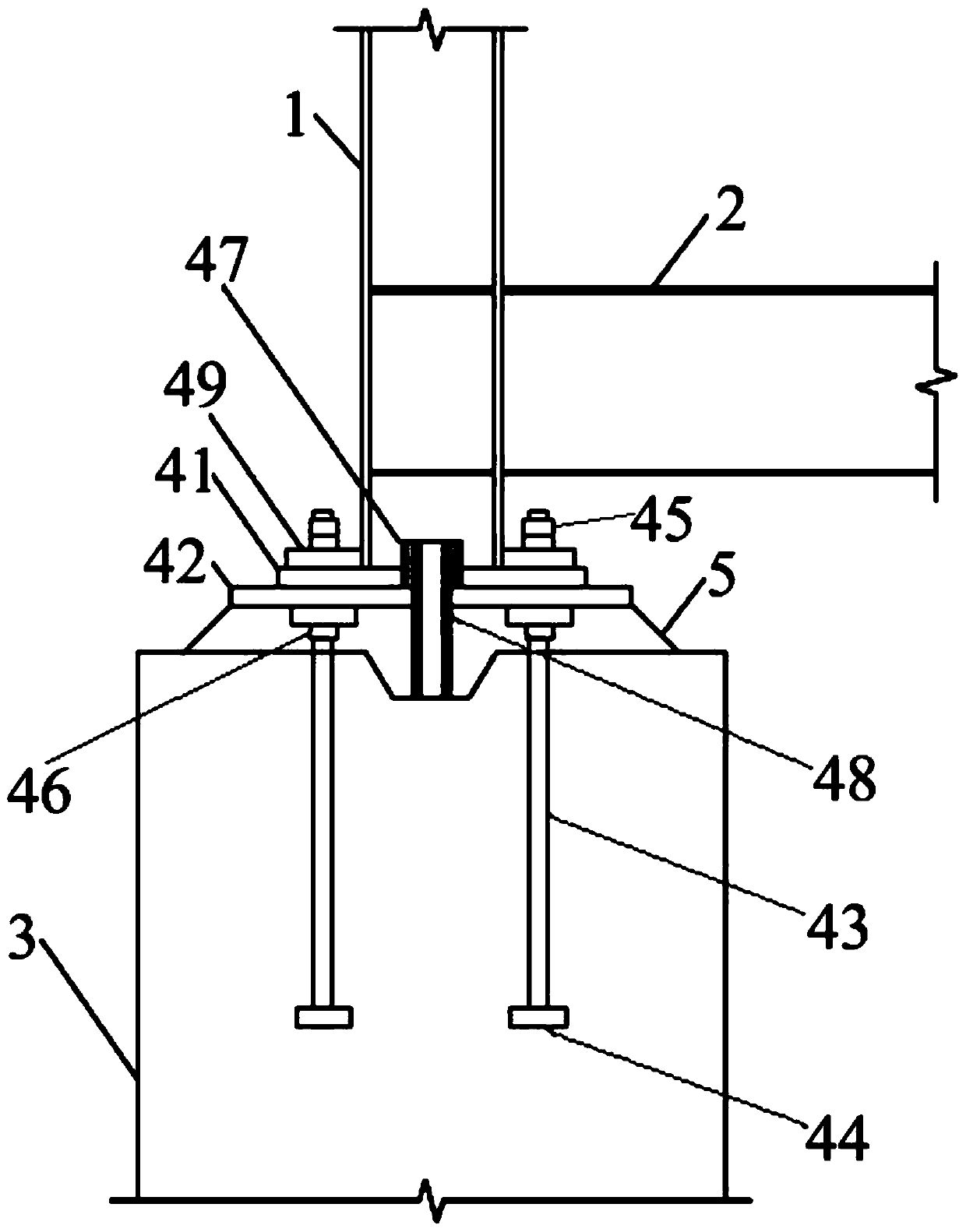

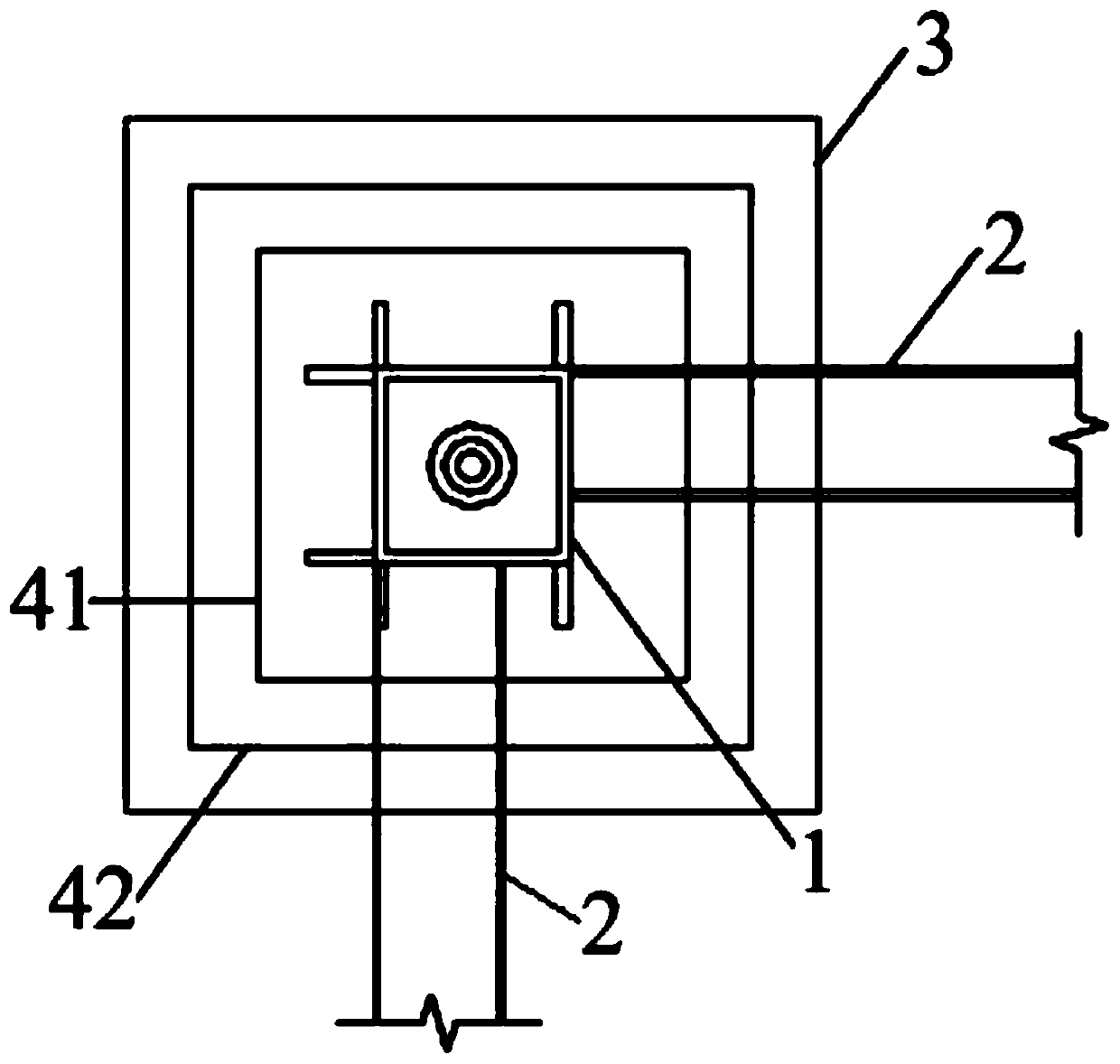

[0028] Modular buildings usually first fix the columns used to support (stress) the building on the pier, and then perform other construction work. In the prior art, in order to quickly realize the fixation between the column and the pier, the column foot of the column and the embedded part in the pier are usually welded and fixed (the embedded part in the column and the pier is made of steel), Or use multiple sets of bolts for connection and fixation instead of welding. Although these fixing methods can quickly realize the connection, when the building needs to be removed later, it faces the problem of difficult demolition. There are also some fixing methods that cancel the shear key between the column and the pier to achieve the purpose of quick disassembly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com