Oven hinge with friction balance mechanism

A balance mechanism and oven technology, applied in the field of oven hinges, can solve the problems of assembly size connection error, weight error, affecting the balance of spring force and oven door self-weight, etc., to achieve reliable hovering, improve reliability, and reduce opening and closing operations force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

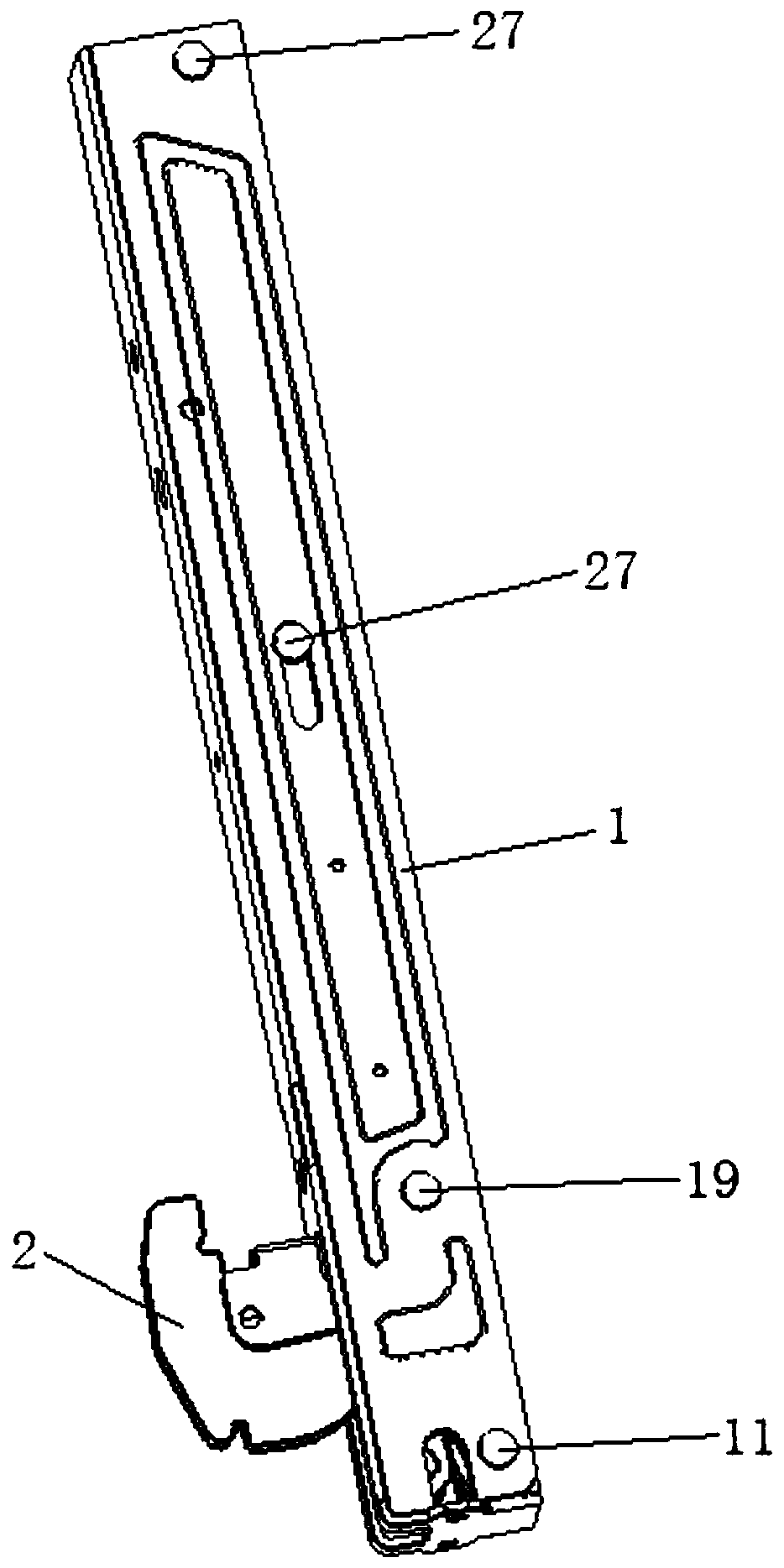

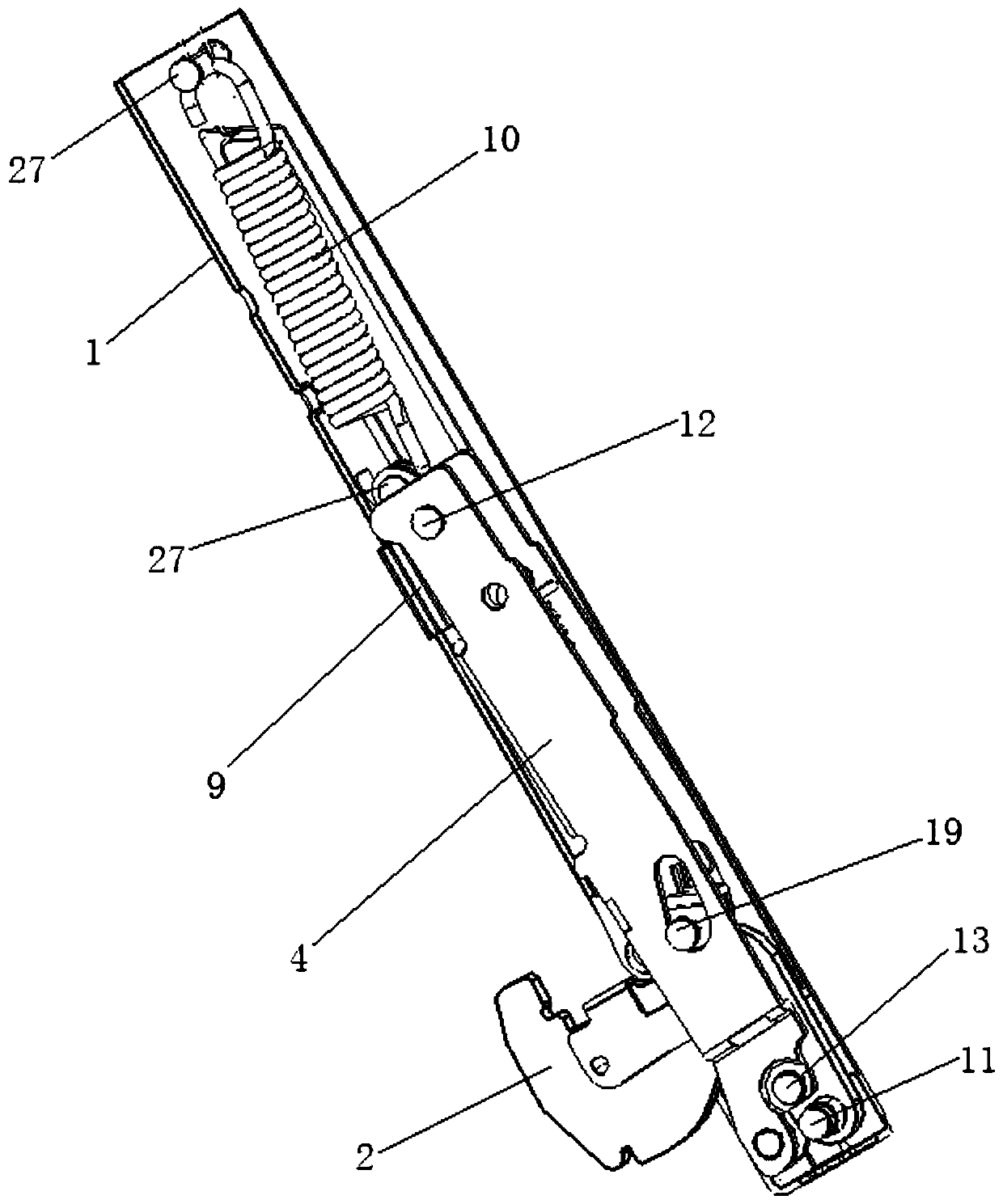

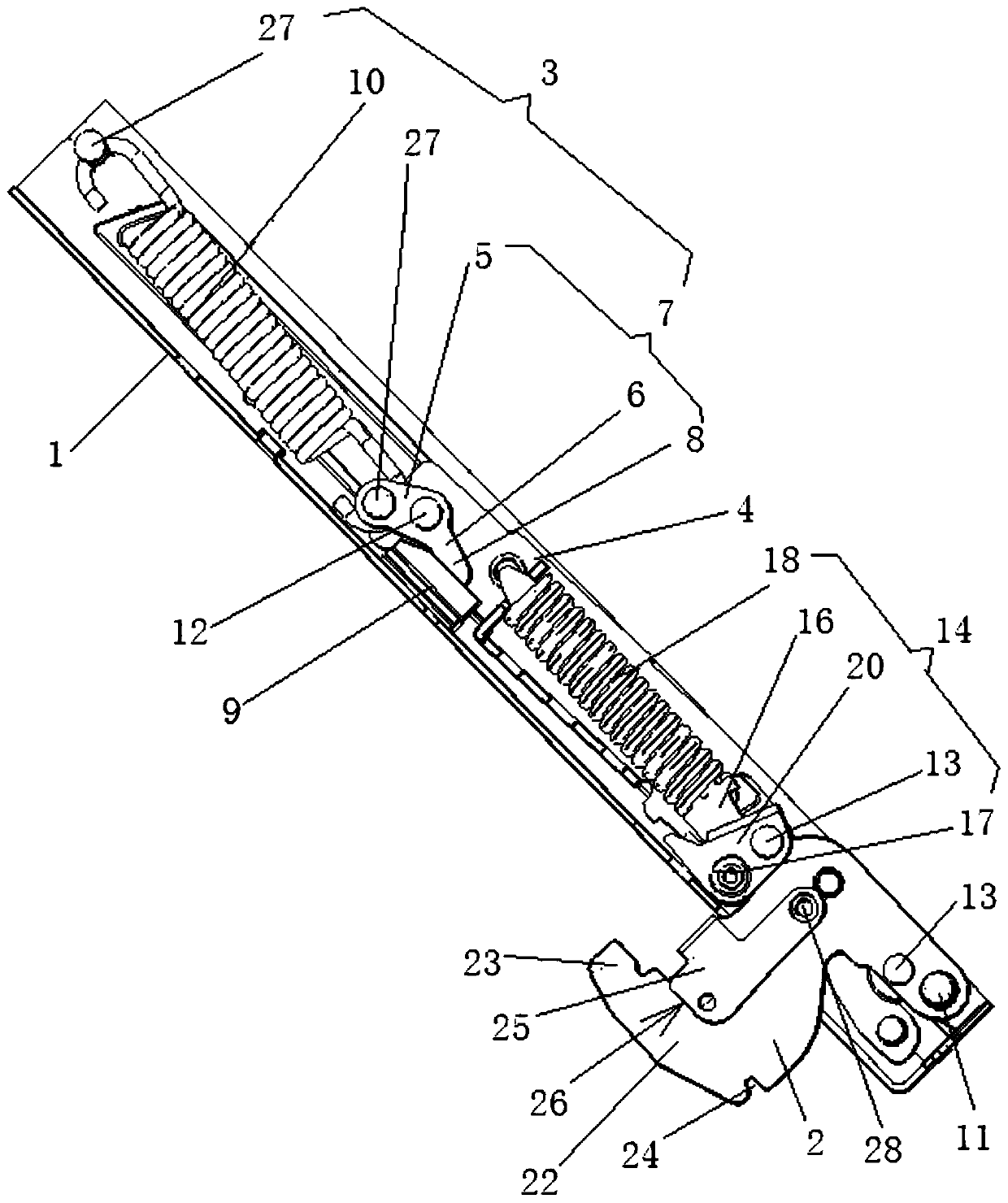

[0035] Such as Figures 1 to 6Shown is an embodiment of an oven hinge with a friction balance mechanism of the present invention, which includes two connecting arms respectively connected to the oven door and the oven cabinet, and the two connecting arms include a long arm 1 and a Short arm 2, one end of the long arm 1 and one end of the short arm 2 are rotatably connected to each other, and the friction between the long arm 1 and the short arm 2 is used to balance the weight of the door after the oven door is opened A balance mechanism 3, the friction balance mechanism 3 includes a fixed friction pair 9 and a movable friction pair 7 in contact with each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com