Strain clamp structure for electric power engineering

A tension clamp, power engineering technology, applied in the direction of adjusting/maintaining mechanical tension, etc., can solve the problems of power transmission system failure, slipping of detached bolts, slipping of transmission lines, etc., to achieve the effect of stable work, reliable fixation, and not easy to slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

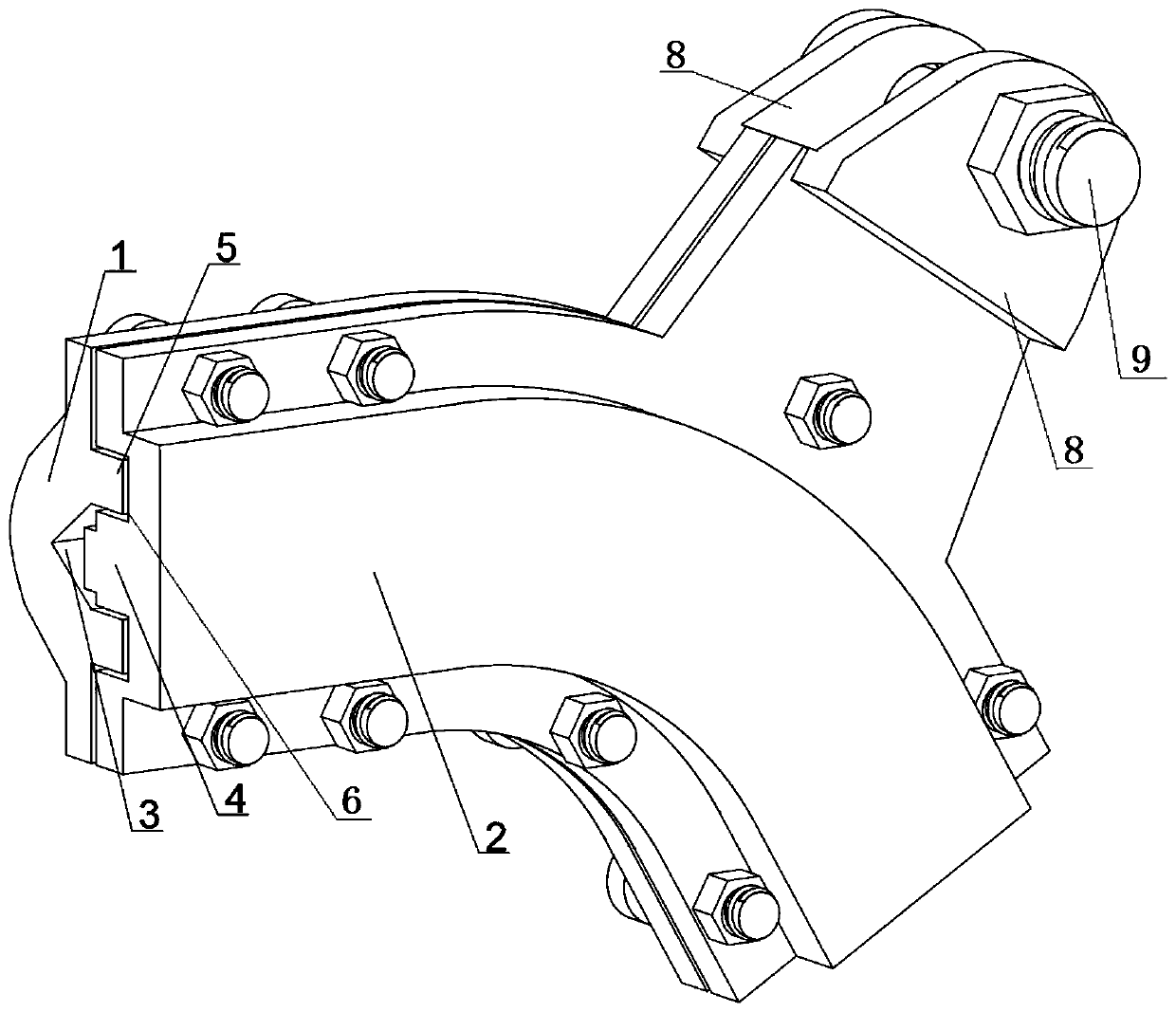

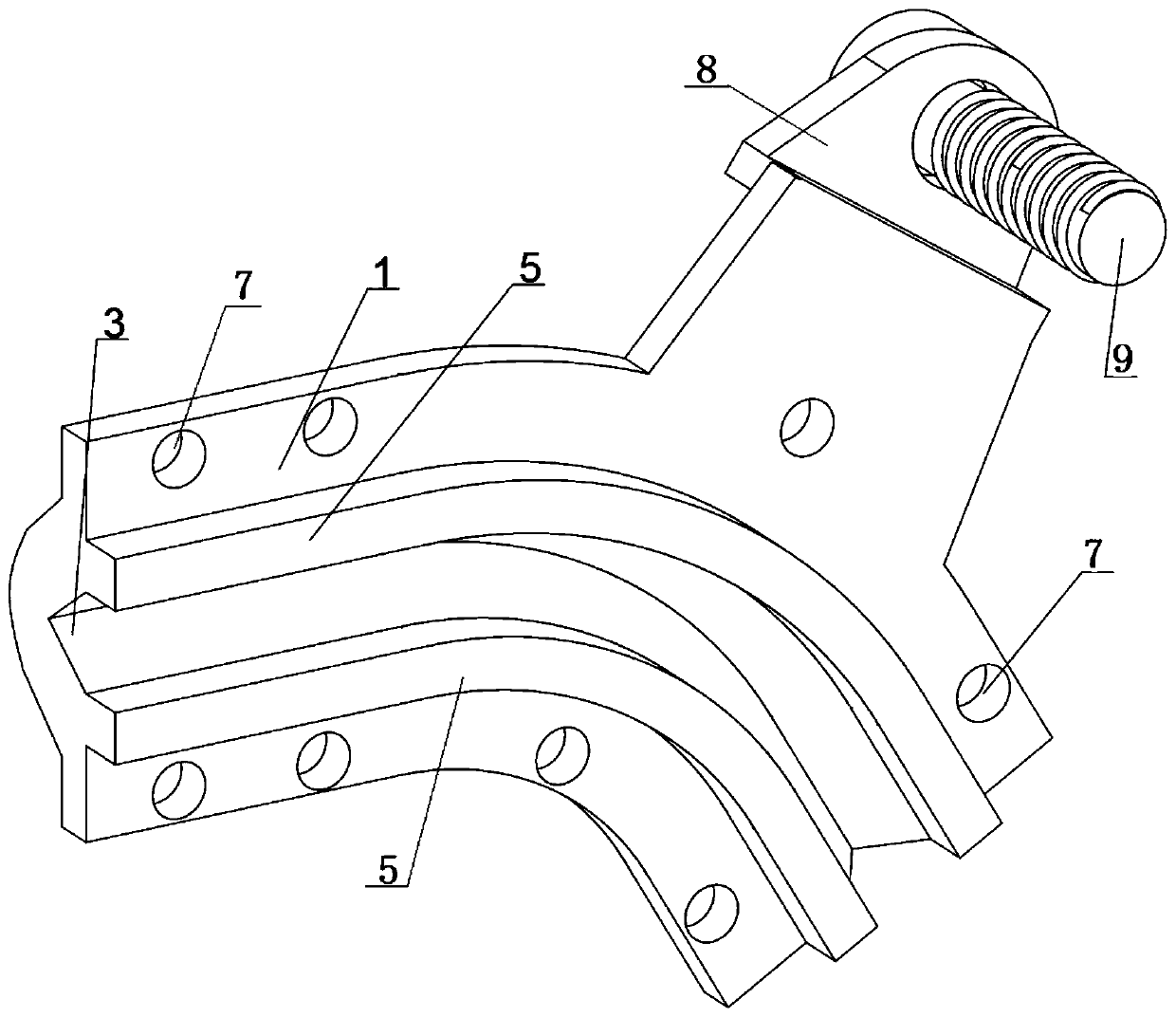

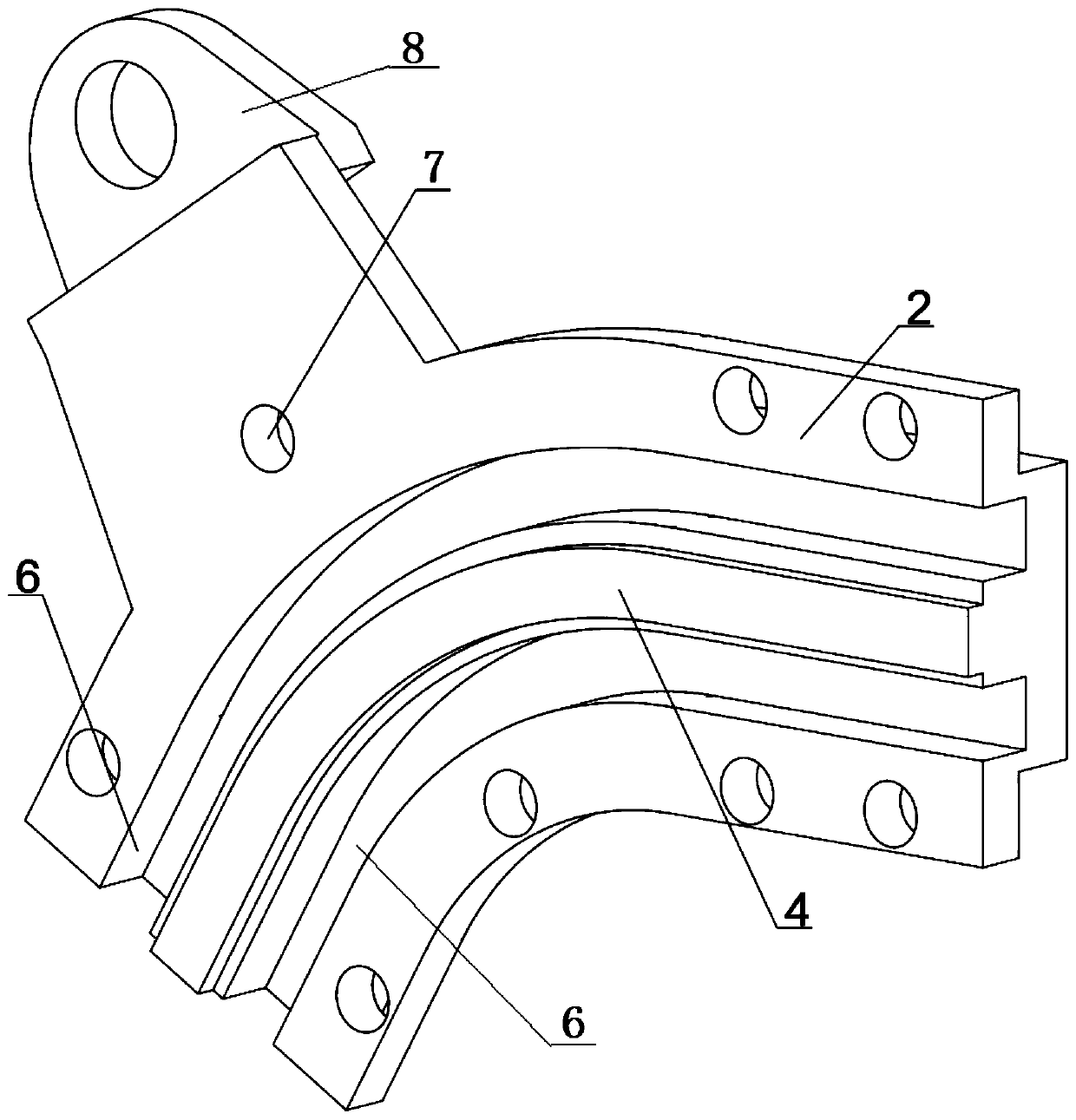

[0024] Such as figure 1 — Figure 4 As shown, a tension-resistant clamp structure for electric power engineering includes a left splint 1 and a right splint 2, the inner surface of the left splint 1 is provided with a wire groove 3, and both sides of the wire groove 3 are provided with convex strips 4, and the right splint 2 The inner surface of the inner surface is provided with a clamping block 5 for clamping the cables in cooperation with the wire groove 3, and the two sides of the clamping block 5 are provided with grooves 6 adapted to the convex strips 4, and the left splint 1 and the right splint 2 are provided with There are several connection holes 7, the left splint 1 and the right splint 2 are connected by bolts passing through the connection holes 7, the left splint 1 and the right splint 2 are both provided with an extension plate 8, and the extension plate 8 is penetrated by a fixing bolt through the connection hole 7 9. The tension clamp structure is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com