Concrete block production equipment with auxiliary demolding device

A demoulding device and concrete block technology, applied in auxiliary forming equipment, unloading devices, manufacturing tools, etc., can solve problems such as difficult concrete cleaning, and achieve the effects of avoiding waste of production time, avoiding waste of concrete raw materials, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

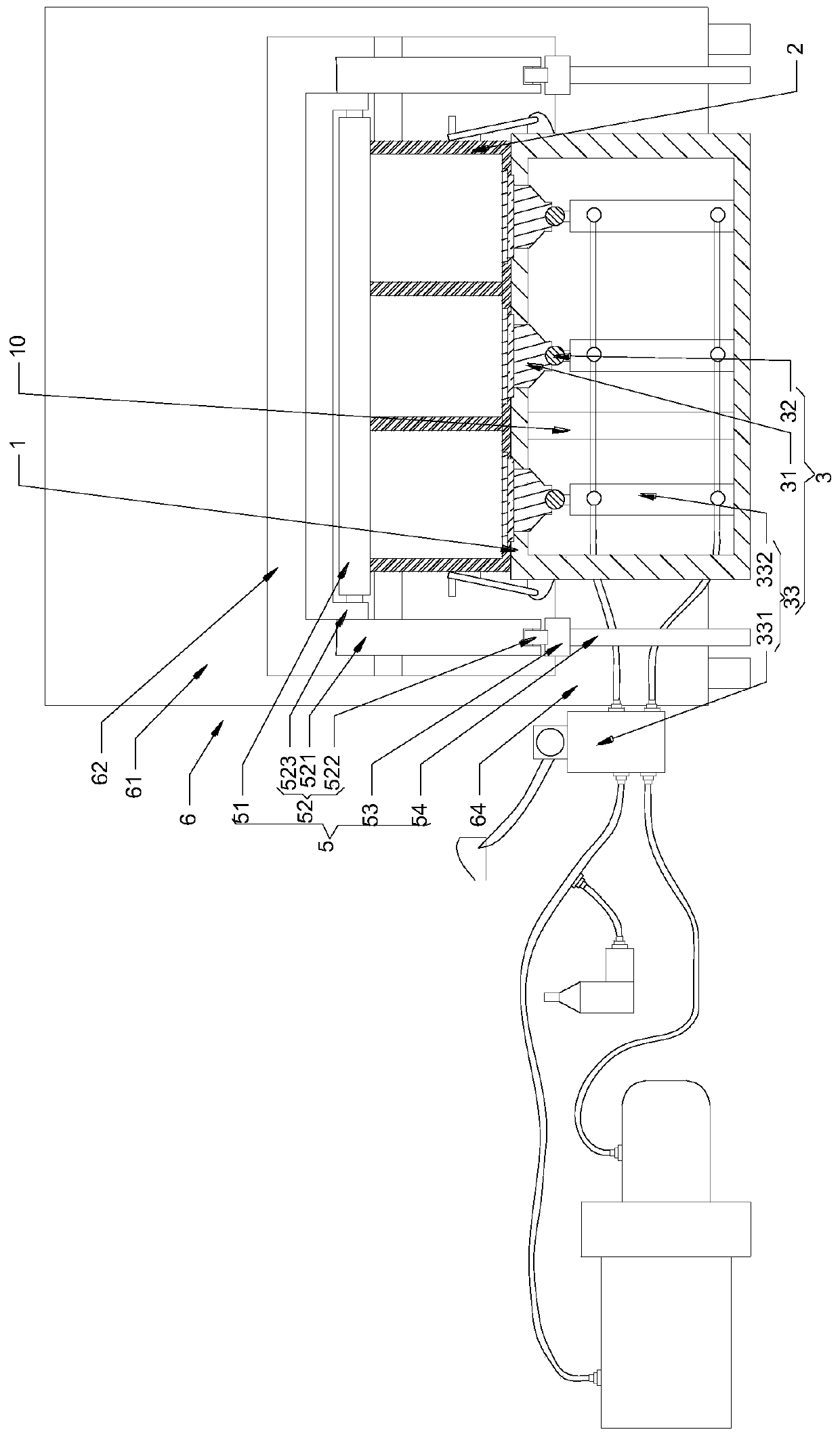

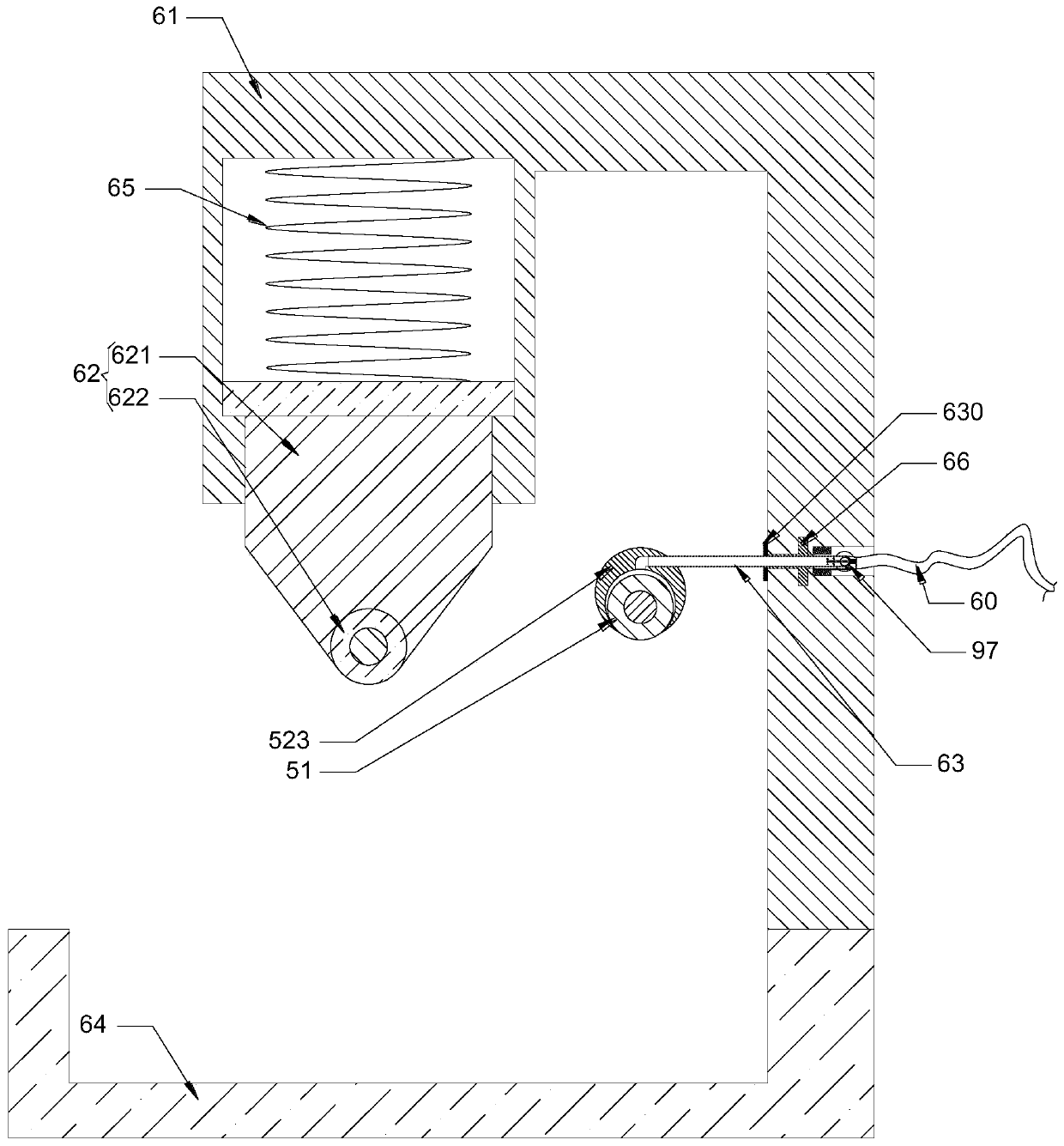

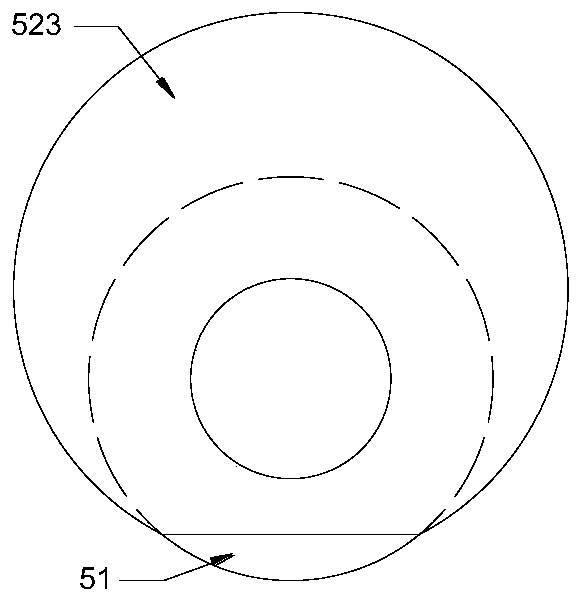

[0029] Such as Figure 1 to Figure 7 As shown, the present embodiment proposes a concrete block production equipment with an auxiliary demoulding device 3, including:

[0030] Support base 1, which stands on the ground through the first stand 10;

[0031] a mold 2, which is installed on the support base 1, and the inner bottom surface of the mold 2 is recessed to form an installation groove communicating with the outside world; and

[0032] Auxiliary demoulding device 3, it comprises: helping to take off seat 31, steel ball 32 and lifting drive mechanism 33, for helping to take off seat 31 to put into in the installation groove, the installation groove inner wall is used for supporting and helping to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com