Flange disc spring, flange disc spring forming tool and forming method

A forming tooling and flanging technology, which is applied in the field of flanging disc spring forming tooling and forming, and flanging disc springs, can solve the problems that the pressure cannot be effectively adjusted, the life of the application equipment is affected, and the position of the disc spring is prone to displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

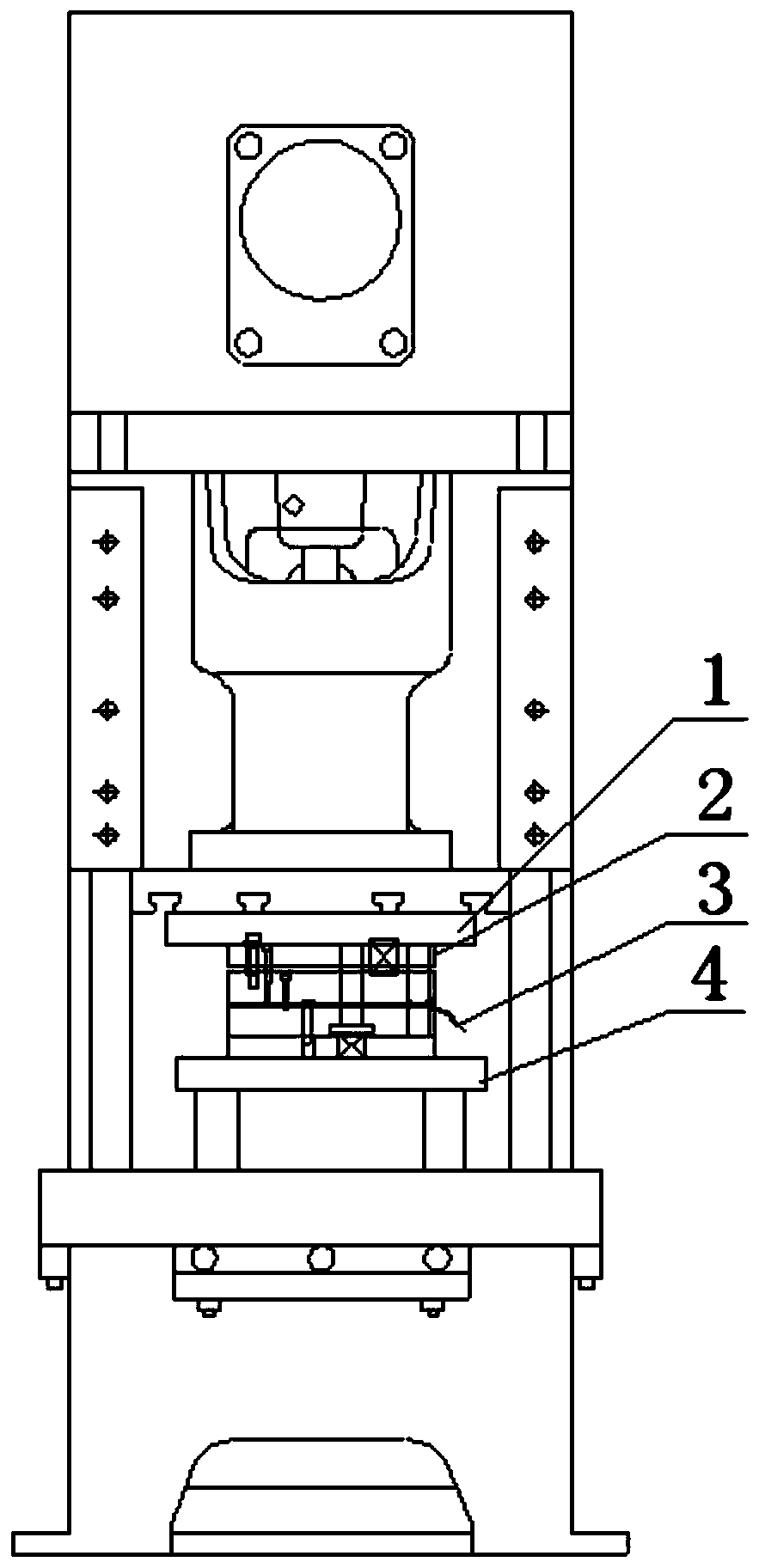

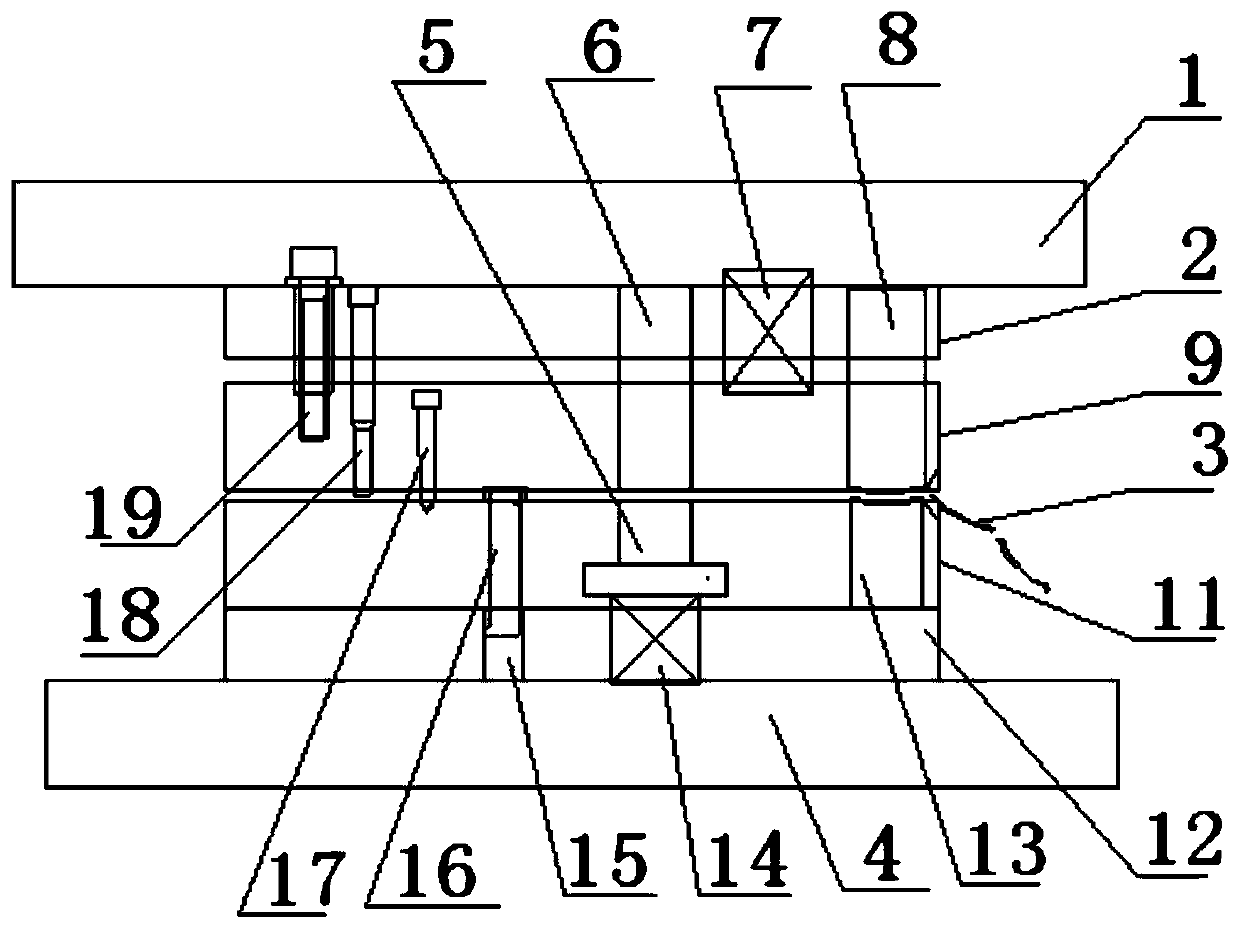

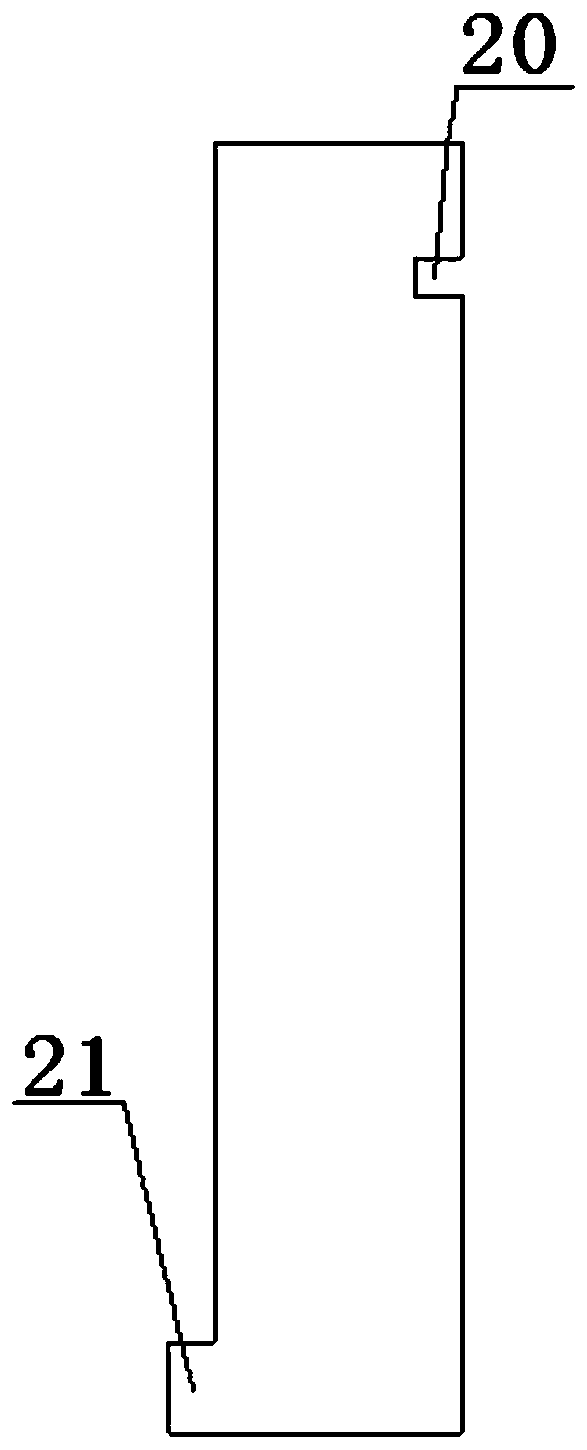

[0027] refer to Figure 1-Figure 4 , the flanging disc spring forming tooling of the present embodiment comprises an upper mold fixing plate 1, an upper template 2, a lower mold, a lower mold fixing plate 4, a pressure plate 11, and a guide plate 9, and the upper mold fixing plate 1 and the upper template 2 are welded connection, the upper template 2 and the guide plate 9 are connected up and down by screws, the lower mold fixing plate 4 is welded and connected with the lower template 12, and the upper template 2 is fixed with an inner punching die 19, a positioning punch 18, an outer punch Cutting die 6, die spring 7 and upper forming template 8, described guide plate 9 is provided with the guide through hole of corresponding inner punching die 19, positioning punch 18, outer punching die 6 and upper forming template 8, and described lower The template 12 is provided with a limit clamping shaft 16, a blanking die 5, and a lower forming template 13. The lower template 12 is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com