Bunching cabling equipment and production process thereof

A cabling and equipment technology, which is used in the manufacture of cables/conductors, insulation of conductors/cables, electrical components, etc., can solve the problems of difficulty in installing spools, inapplicability, etc., and achieve the effect of avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

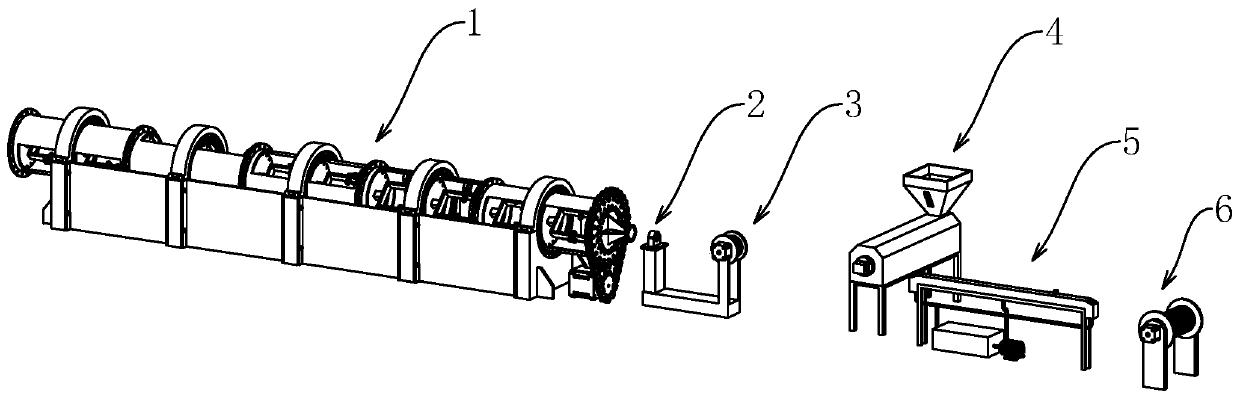

[0054] Such as figure 1 As shown, a wire-bundling equipment includes a rotating stranding device 1, a stranding device 2 for binding the twisted wires together, a tensioning device 3 for tensioning the twisted wires, and an extruding molding device for forming an outer insulating sleeve. A device 4, a cooling device 5 for cooling the insulation jacket, and a winding device 6 for winding the cable.

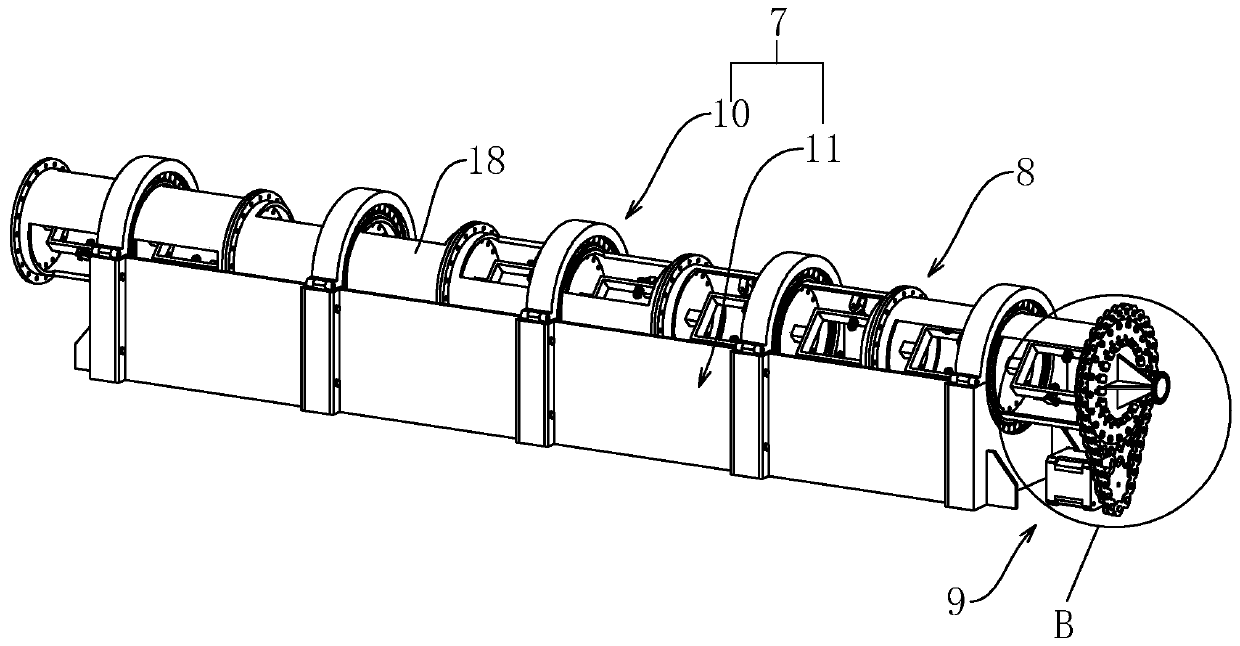

[0055] Such as figure 2 As shown, the rotary stranding device 1 includes a support mechanism 7 , a rotating drum 8 mounted on the supporting mechanism 7 and rotating along its own horizontal axis, and a driving mechanism 9 for driving the rotating drum 8 to rotate.

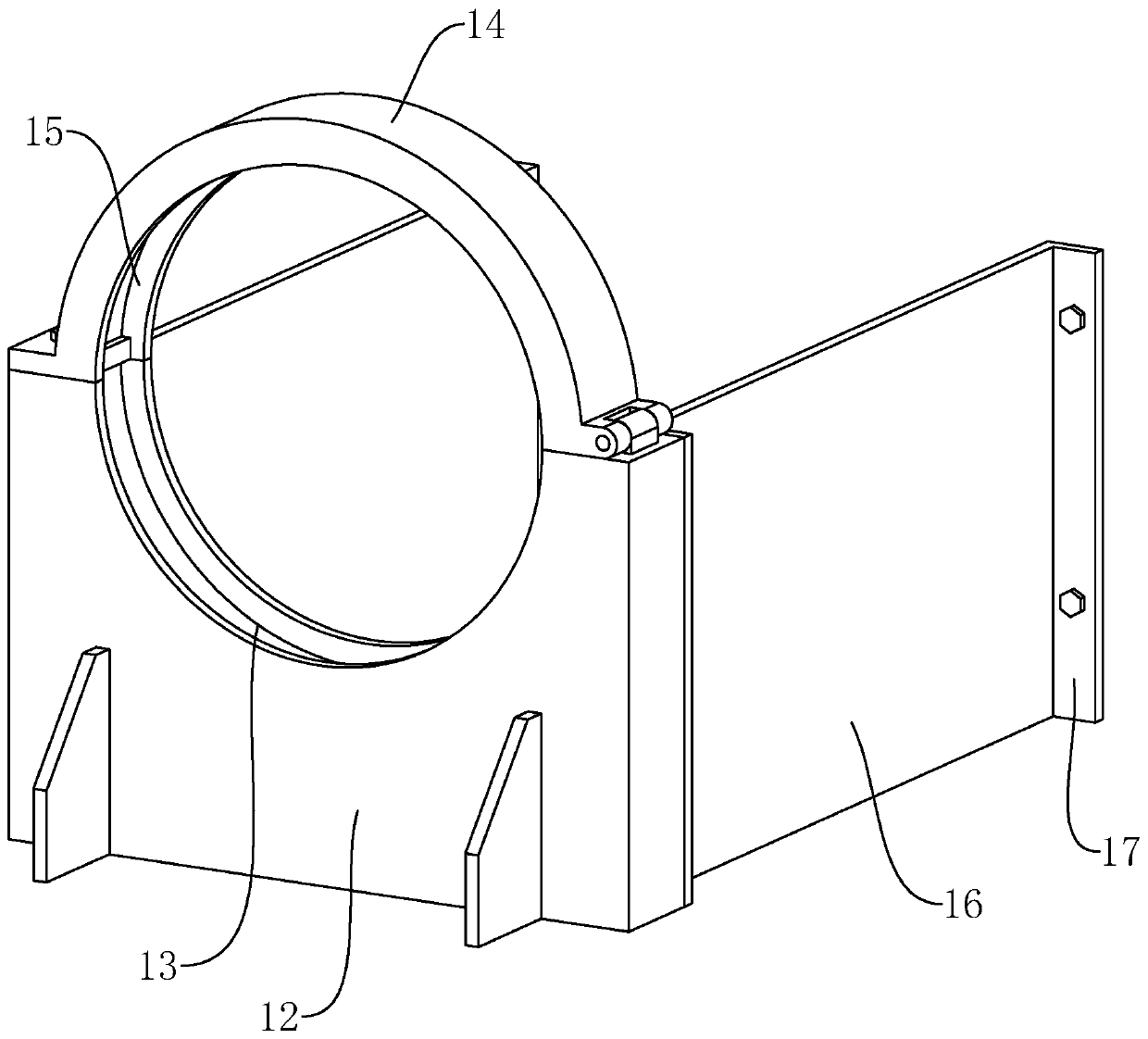

[0056] Such as figure 2 and image 3 As shown, the support mechanism 7 includes a plurality of middle support frames 10 and a protective frame 11 connecting adjacent middle support frames 10, the rotating drum 8 is installed through the middle supporting frame 10, and the rotating drum 8 is played by the protectiv...

Embodiment 2

[0068] A production process for bundled filaments into cables, comprising:

[0069] Step 1: Install the spool

[0070] Put the bobbin into the square frame 29, turn the worm wheel 33 by rotating the worm screw 35 with the handle, the worm wheel 33 rotates to make the screw rods 31 move toward each other, and the contact post 32 is inserted into the bobbin so that the bobbin can only rotate along the axis without will move. Pass the wire core around the first fixed pulley 38 and pass through the through hole 37, then bypass the second fixed pulley 41 and the transition hole 44, and pass through the subsequent wire harness device 2, tensioning device 3, extrusion device 4, cooling The device 5 is connected with the winding roller 58 of the winding device 6 afterward.

[0071] Step 2: Twisting the core

[0072] The driving motor 46 drives the rotary cylinder 8 to rotate, and the tensioning device 3 pulls the wire cores during this process, so that multiple wire cores form twis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com