Multi-process automatic switching device

An automatic switching and multi-process technology, which is applied in the direction of the device for removing poultry viscera, can solve the problems of multiple processing procedures, reduce space utilization, and a large number of operating workers, so as to save labor resources, small space occupancy, and high integration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

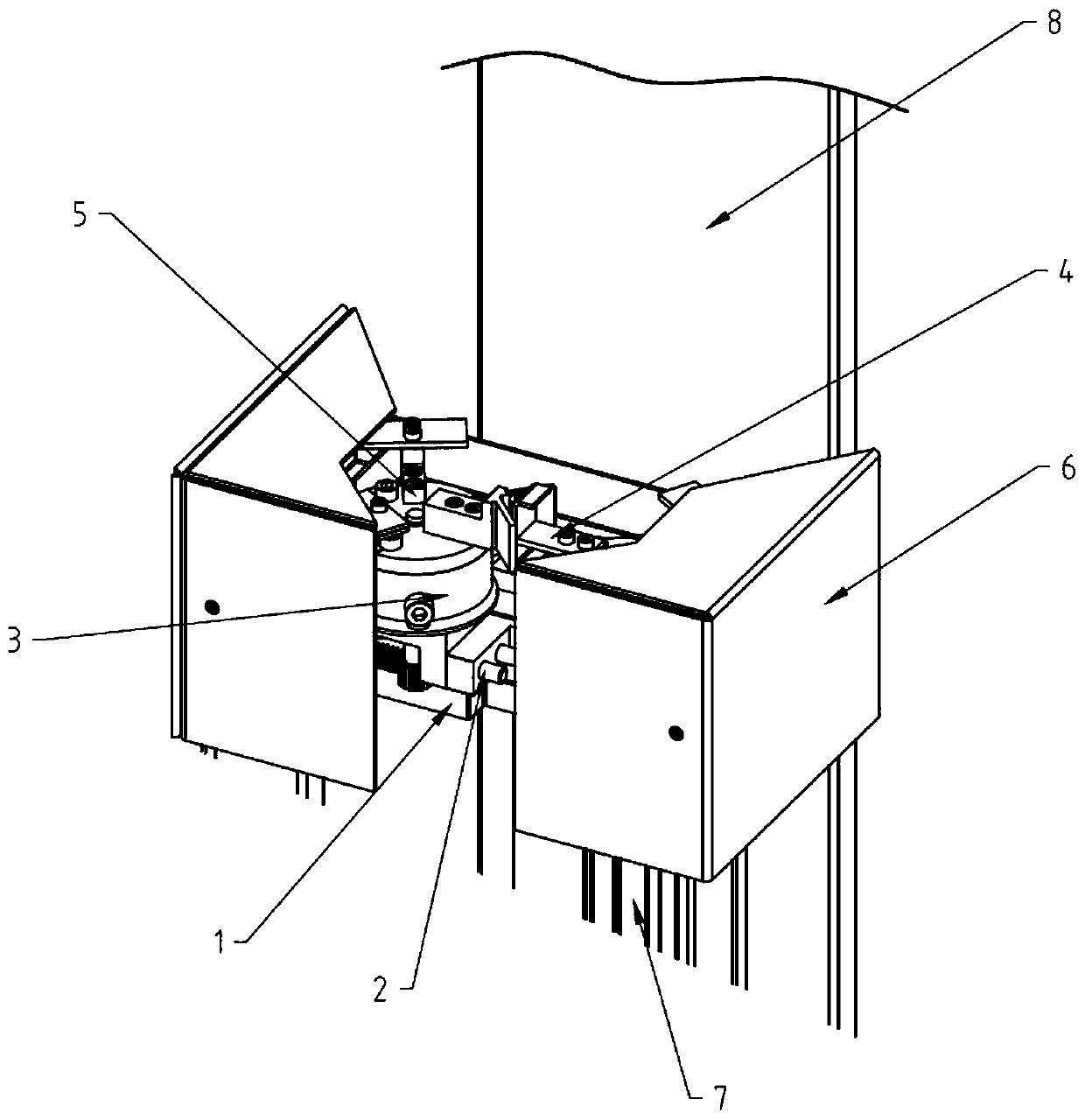

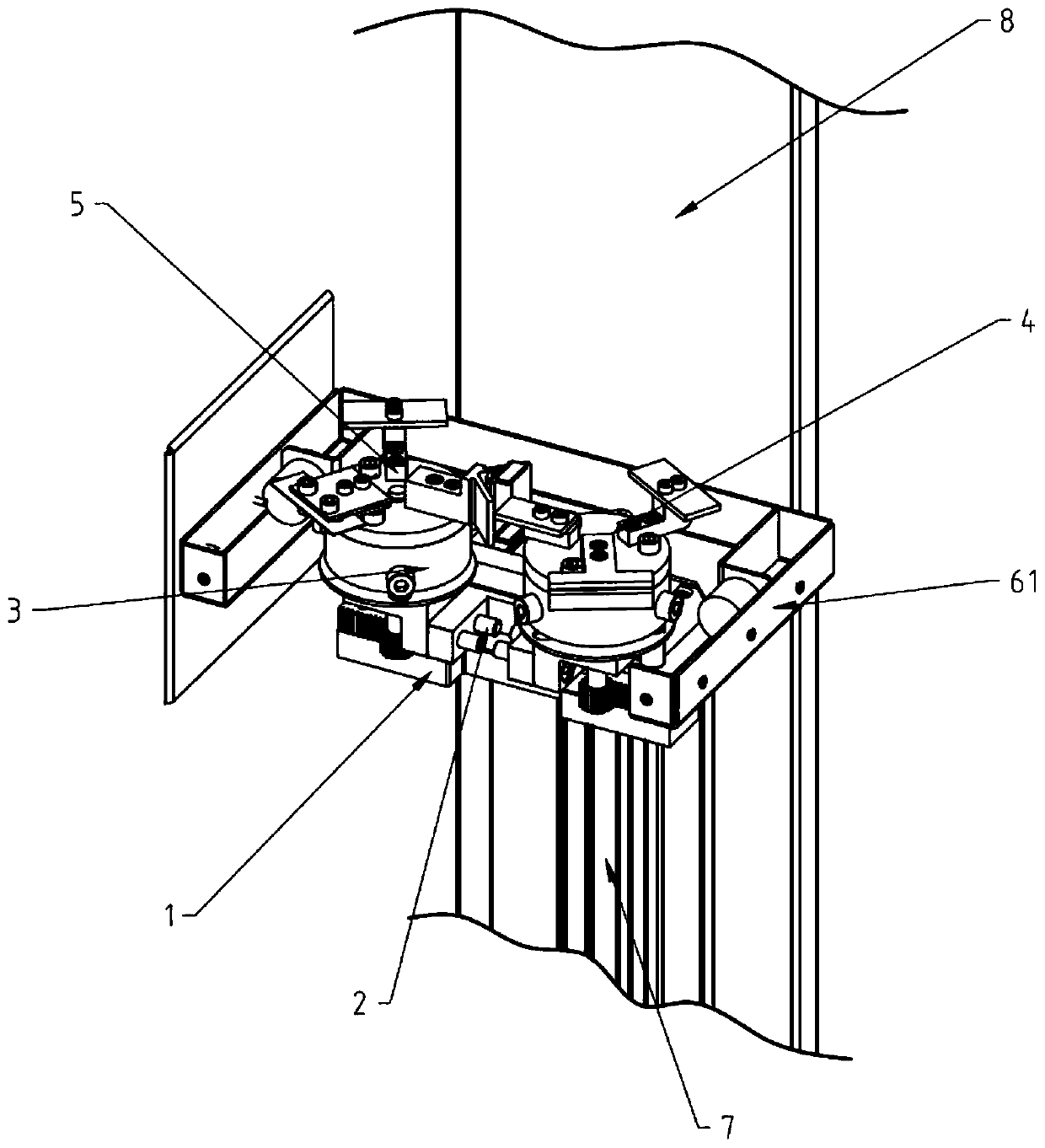

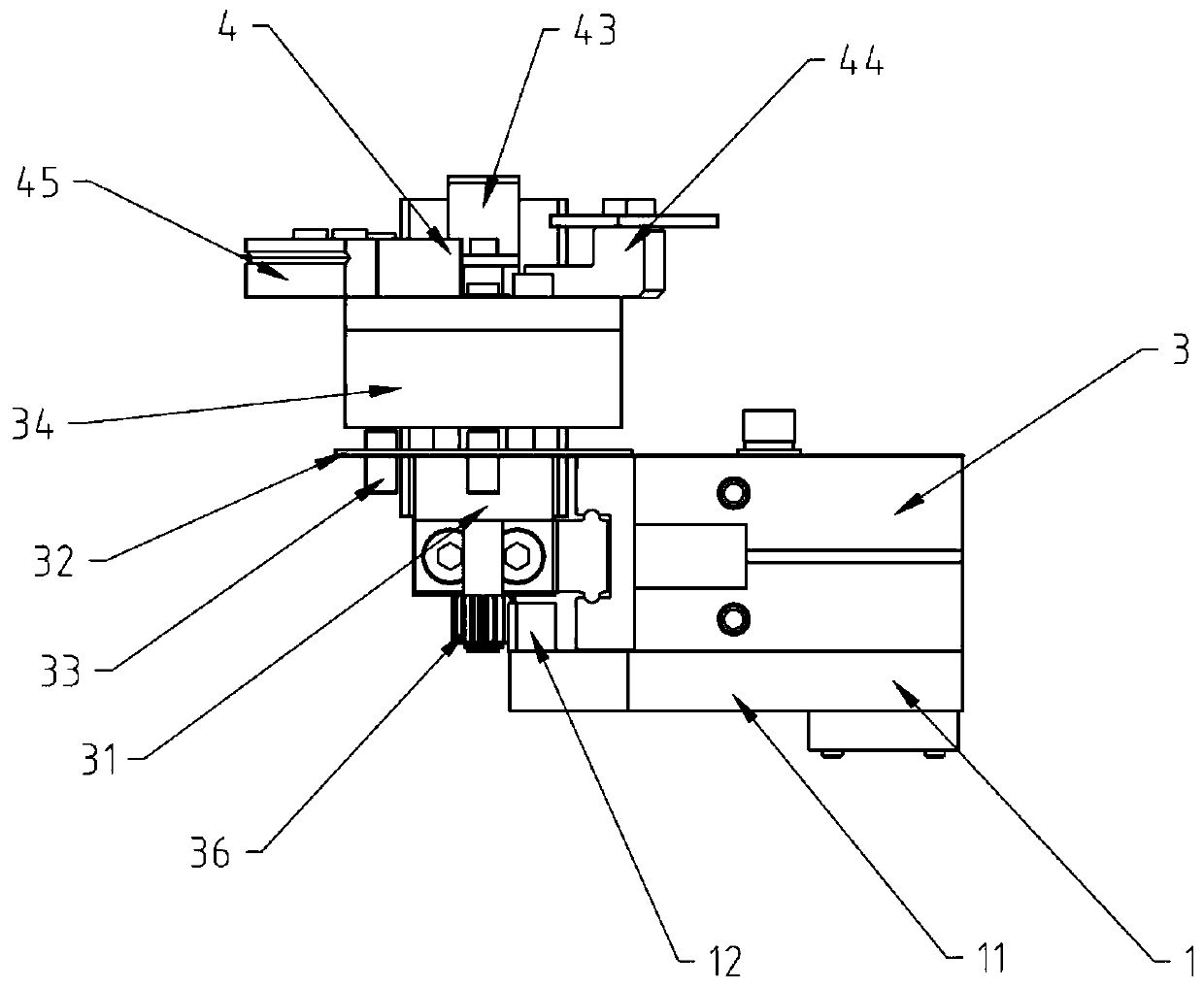

[0031] see Figure 1-Figure 3 , Figure 1-Figure 3 It is a multi-process automatic switching device of this embodiment, including a mounting base 1, a separation assembly 2, a clamping assembly 3 and a work disk, the work disk includes a first work disk 4 and a second work disk 5, and the first work disk A working disk 4 and a second working disk 5 are respectively assembled on the clamping assembly 3, and each working disk is provided with more than two different processing tools, and the processing tools on the first working disk 4 and the second working disk 5 are matched In use, the lower end of the clamping assembly 3 is connected to the separation assembly 2, and can be periodically approached along a certain trajectory under the drive of the separation assembly 2, and the separation assembly 2, the clamping assembly 3 and the working disk are jointly installed on the mounting base 1 .

[0032] Further, in order to meet the needs of automatic control of the processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com