Pipe body cutting device and working method thereof

A technology of cutting device and working method, applied in copper tube cutting and aluminum fields, can solve the problems of easy bending of saw blades, affect quality, increase de-flashing process, etc., and achieve the effect of good cutting quality and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

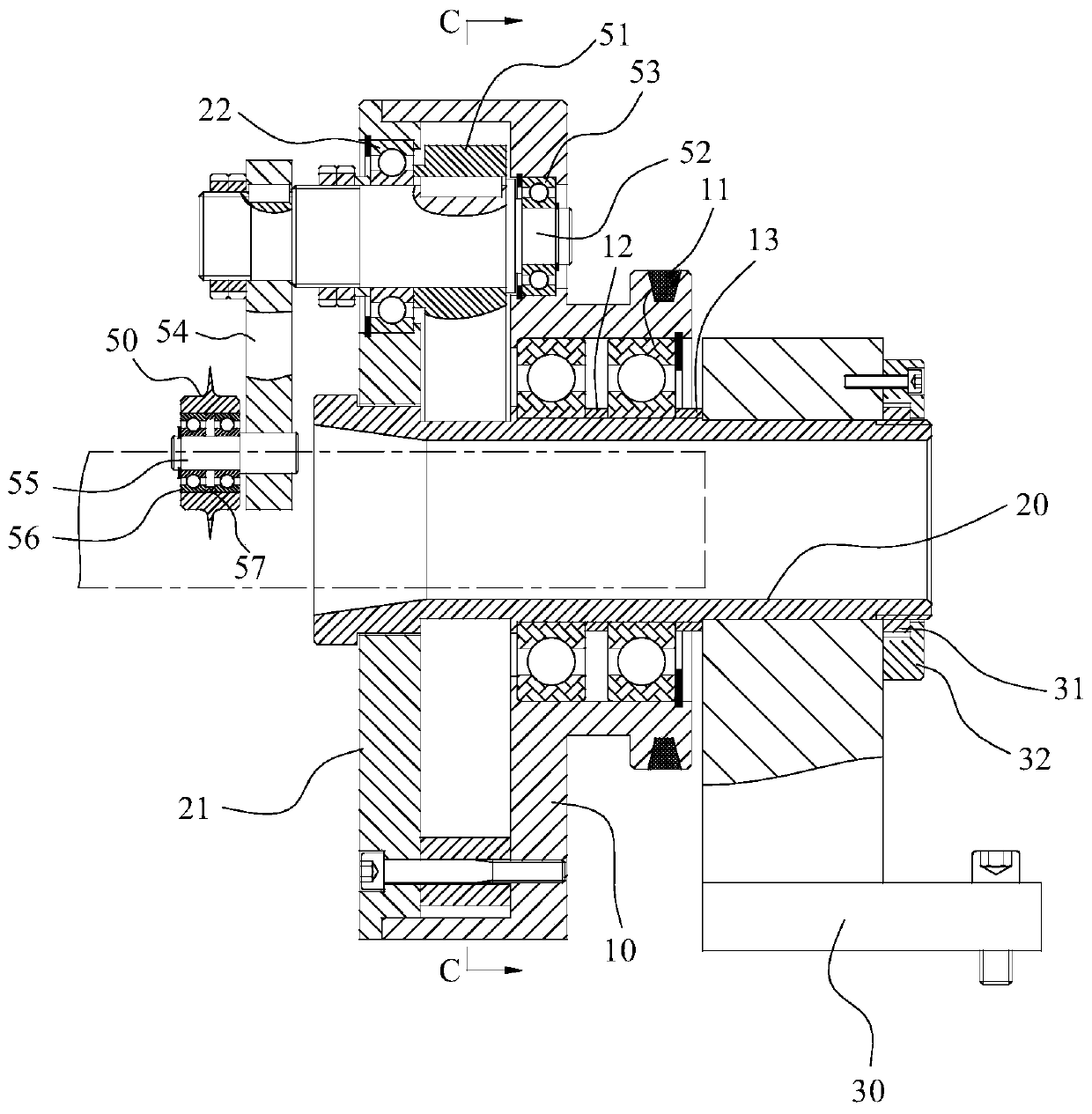

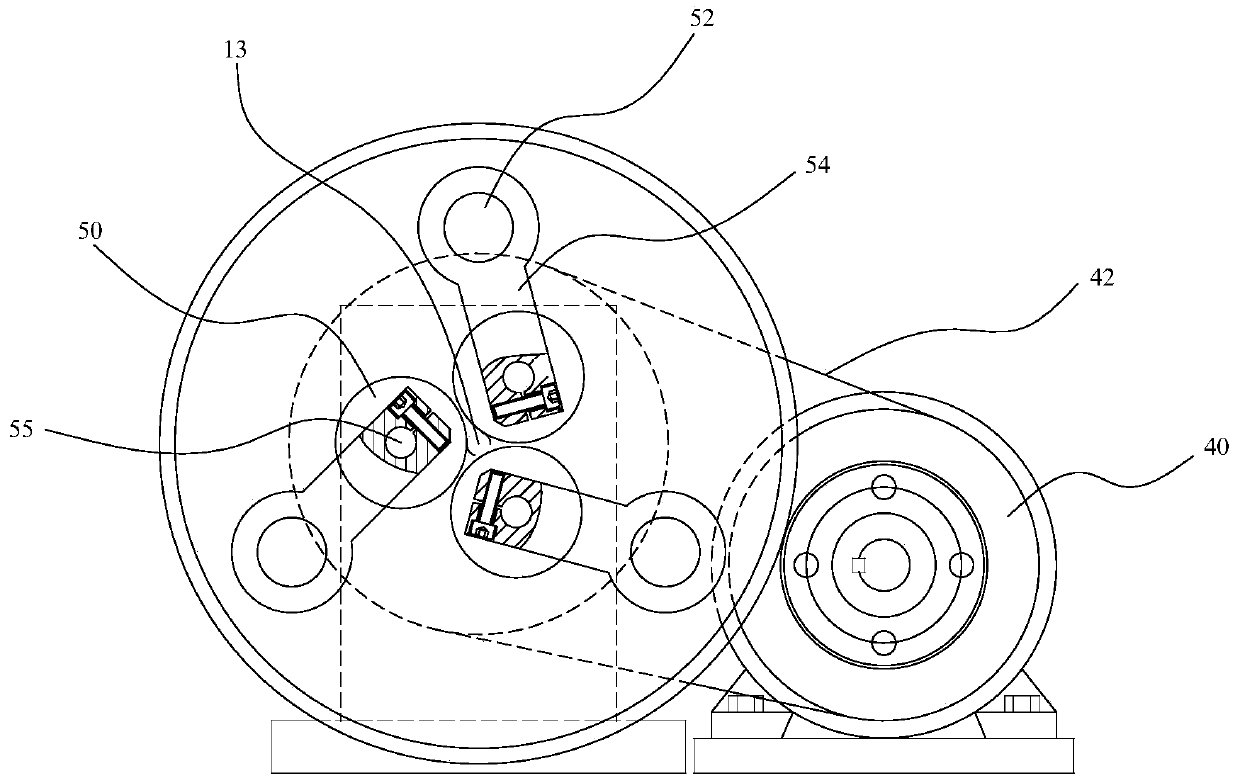

[0024] Such as Figure 1 to Figure 4 As shown, the present embodiment 1 provides a pipe body cutting device, including: a rotary disk 10, a cutting mechanism located on the rotary disk 10, and a driving mechanism; wherein the center of the rotary disk 10 is provided with a through hole to piercing the pipe body; and the driving mechanism is suitable for driving the rotary disk 10 to rotate, so as to drive the cutting structure to rotate to cut the pipe body.

[0025] The rotating disk 10 is sleeved on a supporting shaft 20 ; and the supporting shaft 20 is located on a supporting seat 30 .

[0026] Specifically, the support shaft 20 is installed on the support seat 30, and is locked by the first nut 31 and the gland 32; the rotary table 10 is installed on the support shaft 20 by the first bearing 11; the second A bearing 11 is axially fixed by a first spacer 12 and a second spacer 13 .

[0027] The drive mechanism includes: a motor 40 and a transmission wheel 41 positioned at...

Embodiment 2

[0040] On the basis of embodiment 1, this embodiment 2 provides a working method of a pipe body cutting device, including: piercing the pipe body from the center of the rotary disk; The cutting structure on the turntable rotates to cut the pipe body.

[0041] Specifically, the specific structure and principle of the pipe body cutting device can refer to the description of Embodiment 1, and will not be repeated here.

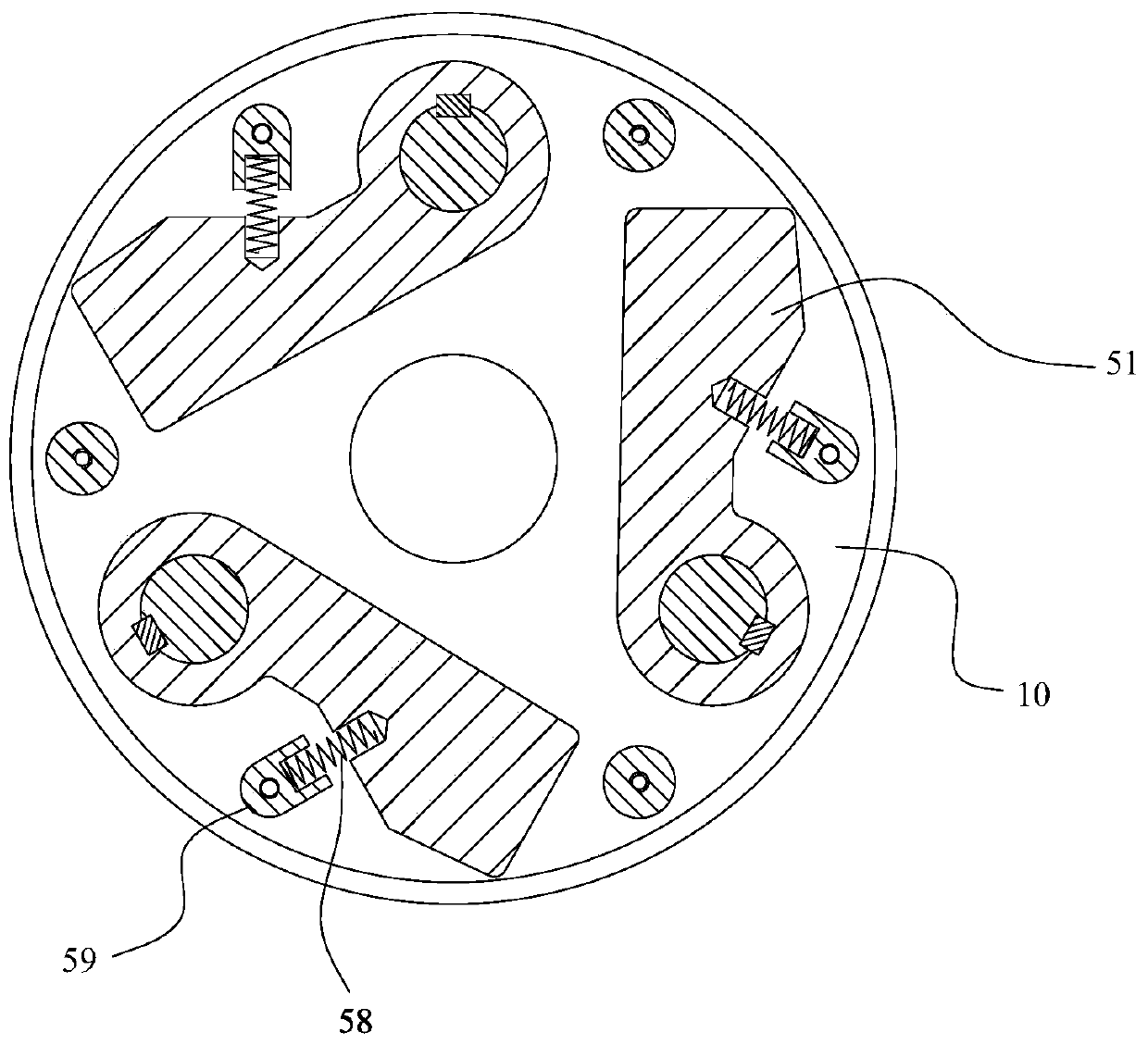

[0042]Further, the cutting mechanism includes: at least two cutting sub-mechanisms; each cutting sub-mechanism is evenly distributed on the rotary disk; Rotary shaft; the cutter is located at one end of the rotary shaft through a connecting assembly; the counterweight is located at the other end of the rotary shaft, and is located on the rotary disc through an elastic limit assembly; when the rotary disc When rotating, each counterweight is adapted to be thrown out of the rotary disc under the action of centrifugal force, and drives the corresponding rotary shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com