Platform device of plasma numerical control cutting machine

A technology of platform device and cutting platform, which is used in plasma welding equipment, auxiliary devices, welding/cutting auxiliary equipment, etc., can solve the problems of encountering obstacles, cutting flame reverse penetration, oxide slag, etc., and achieve cutting quality. Good, easy to maintain, stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

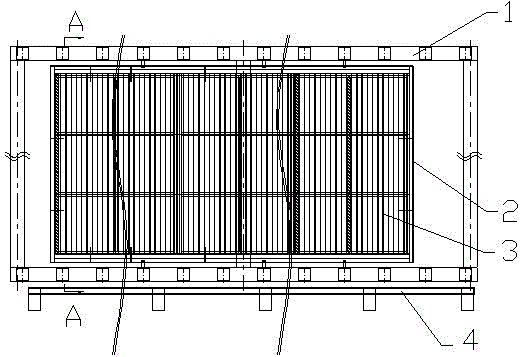

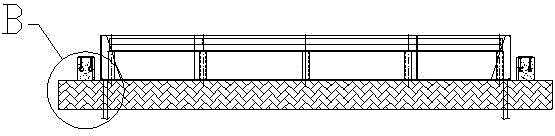

[0029] see Figure 1~Figure 9 , The present invention relates to a plasma CNC cutting machine platform device, which includes a device base 1, a cooling water tank 2, a cutting platform 3 and a cutting machine traveling device 4.

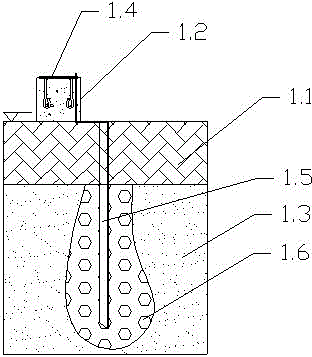

[0030] The device foundation 1 includes a cement floor 1.1, a strip foundation 1.2 arranged in a rectangle is arranged on the cement floor 1.1, the height of the strip foundation 1.2 is 400mm, the width of the strip foundation 1.2 is 300mm, and the bottom of the cement floor 1.1 is soil 1.3, An anchor plate 1.4 is arranged inside the strip foundation 1.2, and a ground flat steel 1.5 bent at a right angle is arranged downward from the inside of the strip foundation 1.2. 3m, the part of the ground flat steel 1.5 in the soil 1.3 is covered by the coating layer 1.6, and the coating layer 1.6 is a combination of salt and charcoal or a drag reducing agent. The inner edge of the strip foundation 1.2 is provided with a plurality of support frames. The str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com