Laser cutting process for hot-rolled steel plate

A hot-rolled steel plate, laser cutting technology, applied in laser welding equipment, manufacturing tools, metal processing equipment and other directions, can solve the problems of rough cut surface, easy deformation of steel plate, poor processing accuracy of hot-rolled steel plate, etc., to achieve good cutting quality , the effect of small vibration and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

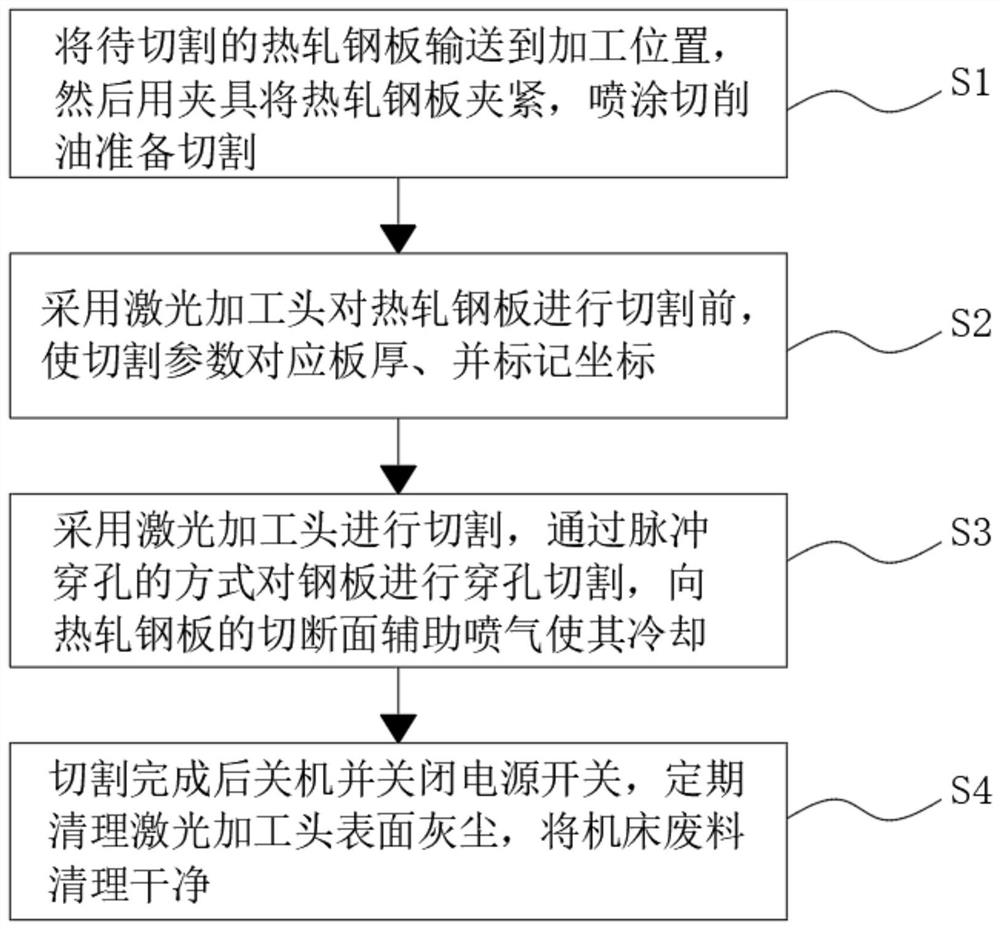

[0024] A laser cutting process for hot-rolled steel plates, comprising the following steps:

[0025] S1: Transport the hot-rolled steel plate to be cut to the processing position through the transmission equipment, then clamp the hot-rolled steel plate with a clamp, spray cutting oil according to the thickness of the hot-rolled steel plate to be processed, and prepare for cutting. If the thickness of the hot-rolled steel plate is greater than 10mm, then Spray a layer of cutting oil on the surface of the hot-rolled steel plate to be processed. Applying oil to the surface of the workpiece during processing can get a better cutting effect and improve the cutting quality. After spraying the cutting oil, it takes a period of time before cutting, and the interval is longer than 8min, the cutting oil is immersed in the hot-rolled steel plate;

[0026] S2: Before using the laser processing head to cut the hot-rolled steel plate, make the cutting parameters correspond to the plate thic...

Embodiment 2

[0030] A laser cutting process for hot-rolled steel plates, comprising the following steps:

[0031] S1: Transport the hot-rolled steel plate to be cut to the processing position through the transmission equipment, then clamp the hot-rolled steel plate with a clamp, spray cutting oil according to the thickness of the hot-rolled steel plate to be processed, and prepare for cutting. If the thickness of the hot-rolled steel plate is greater than 10mm, then Spray a layer of cutting oil on the surface of the hot-rolled steel plate to be processed. Applying oil to the surface of the workpiece during processing can get a better cutting effect and improve the cutting quality. After spraying the cutting oil, it takes a period of time before cutting, and the interval is longer than 8min, the cutting oil is immersed in the hot-rolled steel plate;

[0032] S2: Before using the laser processing head to cut the hot-rolled steel plate, make the cutting parameters correspond to the plate thic...

Embodiment 3

[0036] A laser cutting process for hot-rolled steel plates, comprising the following steps:

[0037]S1: Transport the hot-rolled steel plate to be cut to the processing position through the transmission equipment, then clamp the hot-rolled steel plate with a clamp, spray cutting oil according to the thickness of the hot-rolled steel plate to be processed, and prepare for cutting. If the thickness of the hot-rolled steel plate is greater than 10mm, then Spray a layer of cutting oil on the surface of the hot-rolled steel plate to be processed. Applying oil to the surface of the workpiece during processing can get a better cutting effect and improve the cutting quality. After spraying the cutting oil, it takes a period of time before cutting, and the interval is longer than 8min, the cutting oil is immersed in the hot-rolled steel plate;

[0038] S2: Before using the laser processing head to cut the hot-rolled steel plate, make the cutting parameters correspond to the plate thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com