Transfer device used for buried pipeline installation

A transfer device and pipeline technology, applied in tool storage devices, workshop equipment, manufacturing tools, etc., can solve the problems of high resource occupation, complicated laying methods, and low laying efficiency, and achieve low labor intensity, improve laying efficiency, and occupy resources. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

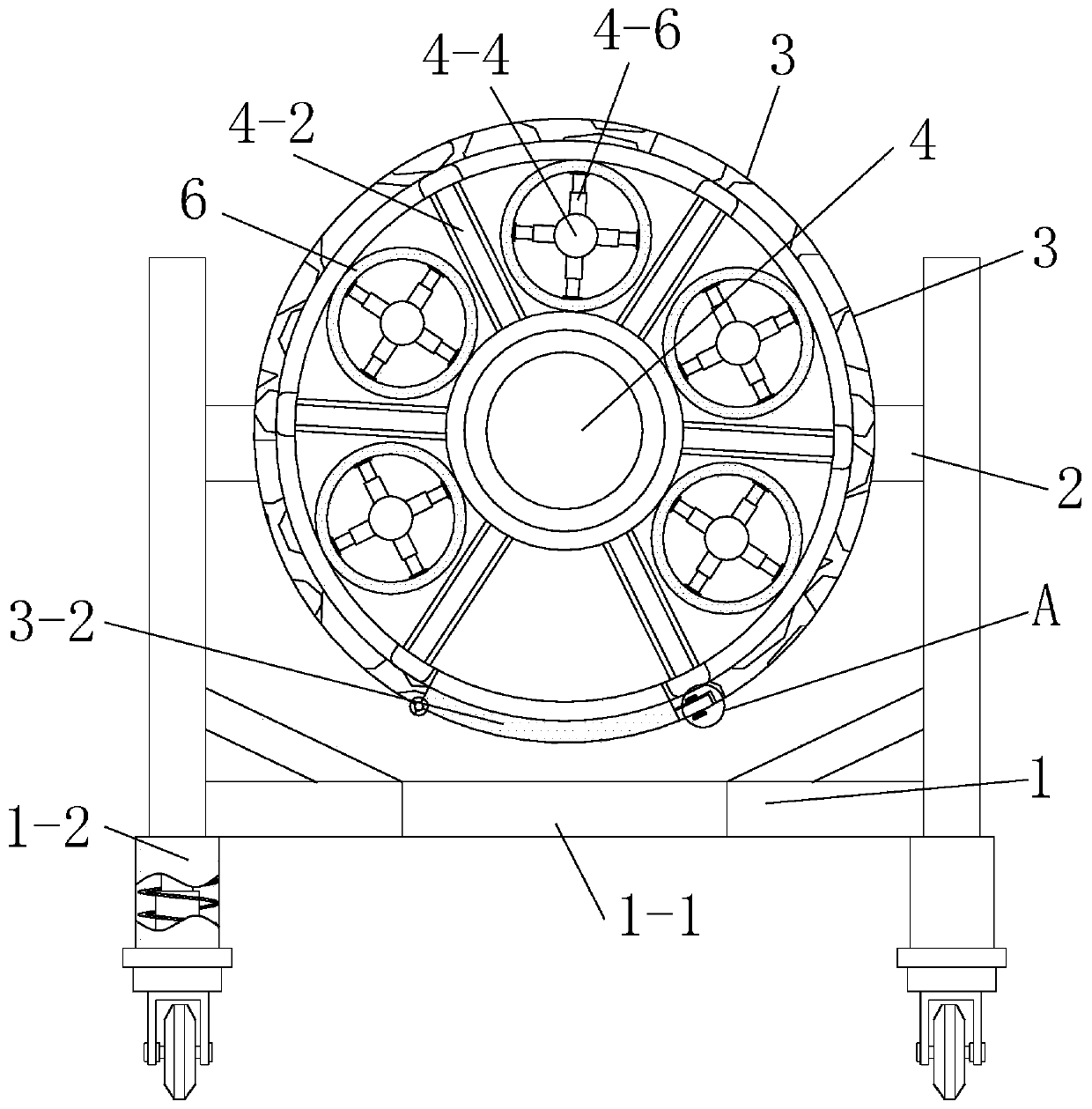

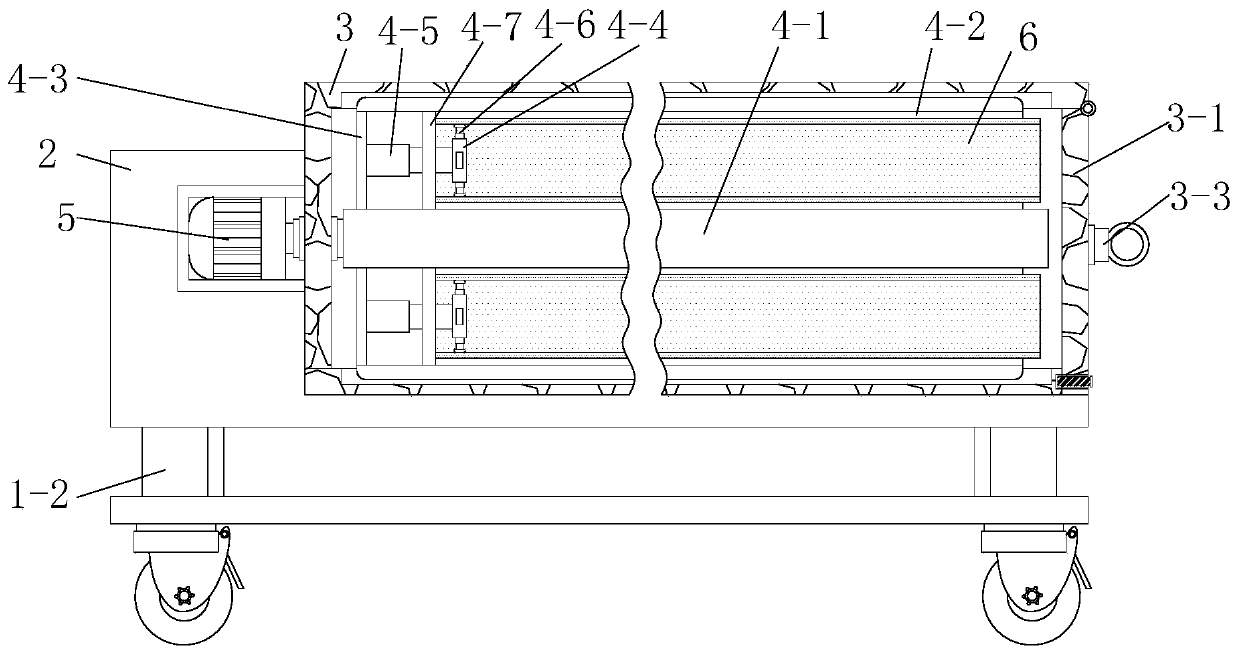

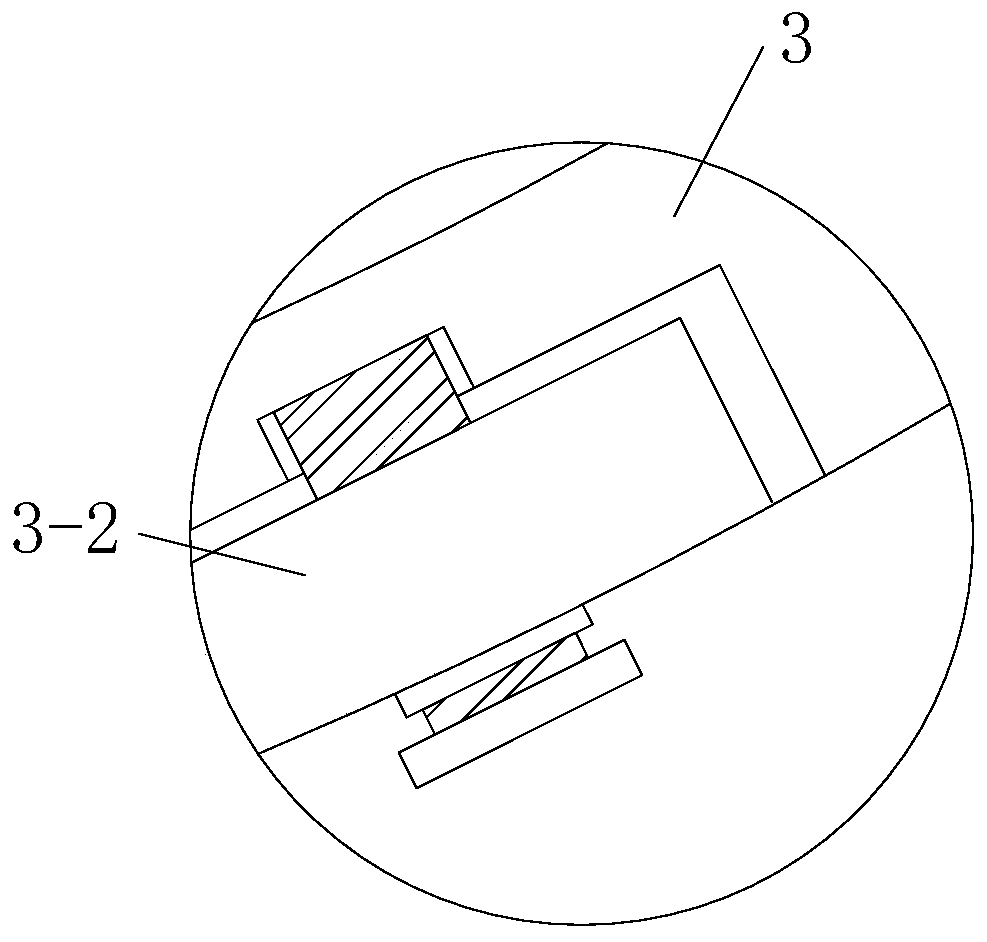

[0018] see Figure 1 ~ Figure 3 , a transfer device for installation of buried pipelines, comprising a flatbed truck 1, a support fixture 2 is fixedly connected to the flatbed trolley 1, and a cylindrical storage box horizontally arranged along the length direction of the flatbed trolley is fixed on the support fixture 2. Box 3, in the storage box 3 is provided with a runner 4 connected to it in rotation, the runner 4 is provided with a central rotating shaft 4-1, and a plurality of peripheral rollers are fixed around the central rotating shaft 4-1 For the partitions 4 - 2 arranged uniformly and extending in the radial direction, a pipe nest is formed between two adjacent partitions 4 - 2 for arranging the pipes 6 .

[0019] The central rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com