Three-dimensional vision grasping method of mobile robot for unmanned fdm additive manufacturing

A mobile robot and 3D vision technology, applied in the direction of manufacturing tools, program control manipulators, manipulators, etc., can solve the problems of scalability affecting the scalability of the printing system, increasing equipment costs, and large cost expenses, so as to avoid poor scalability , easy to expand, and improve the effect of site restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

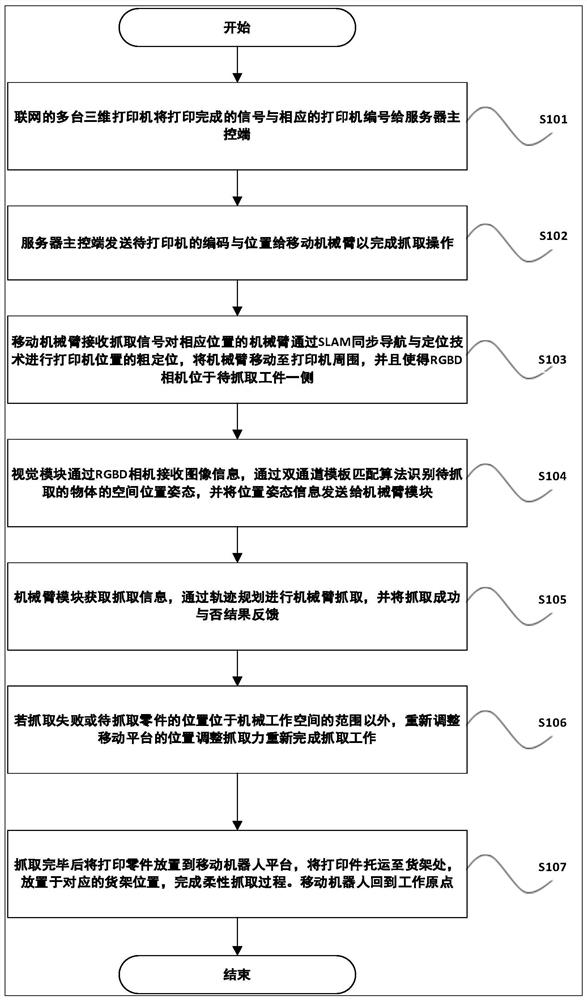

[0058] figure 1 It is a flow chart of a two-step positioning and grabbing scheme with hand, eye, and foot coordination for mobile robotic arms to grab and store printed parts of multiple FDM 3D printers. Such as figure 1 shown, including:

[0059] The present invention provides a two-step positioning and grabbing solution for a mobile robotic arm with hand-eye-foot coordination, including:

[0060] Step S101, multiple 3D printers and mobile robots have communicated with the main server, and the networked printers can respond to the printing instructions of the corresponding parts. After the printing is completed, the corresponding printer number, the model of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com