A molding machine for extruding and preventing breakage of rigid foamed plastic particles

A foam plastic granule, anti-break technology, applied in the field of rigid foam plastic granule extrusion anti-break molding machine, can solve the problems of loosening, material breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] as attached figure 1 To attach Figure 7 Shown:

[0029] The present invention provides a molding machine for extruding and preventing fracture of rigid foamed plastic particles.

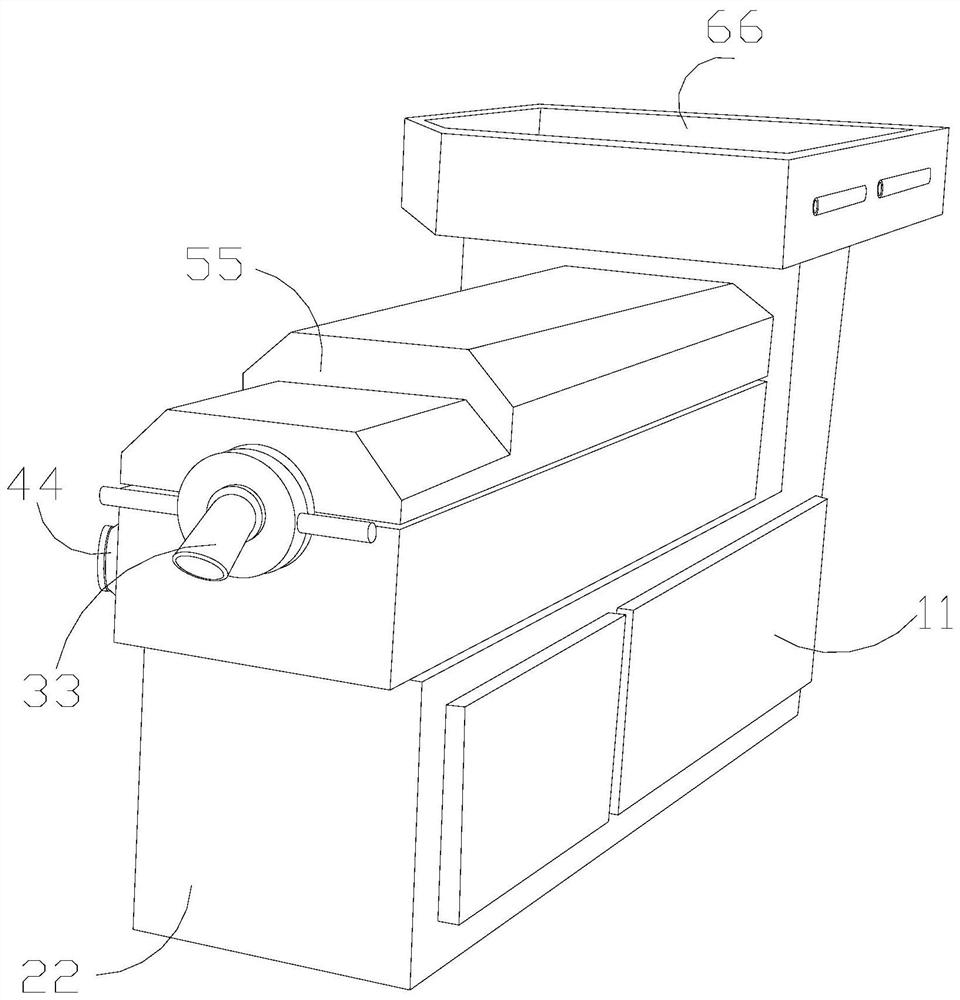

[0030] The bottom box 11 is connected to the bottom control end 22, the top of the bottom control end 22 is equipped with a processing box 55, the auxiliary port 33 runs through the inside of the processing box 55, and the molding extrusion hole 44 is embedded in the processing box 55 Inside, the outer surface of the processing box 55 is connected to the outer surface of the introduction port 66 .

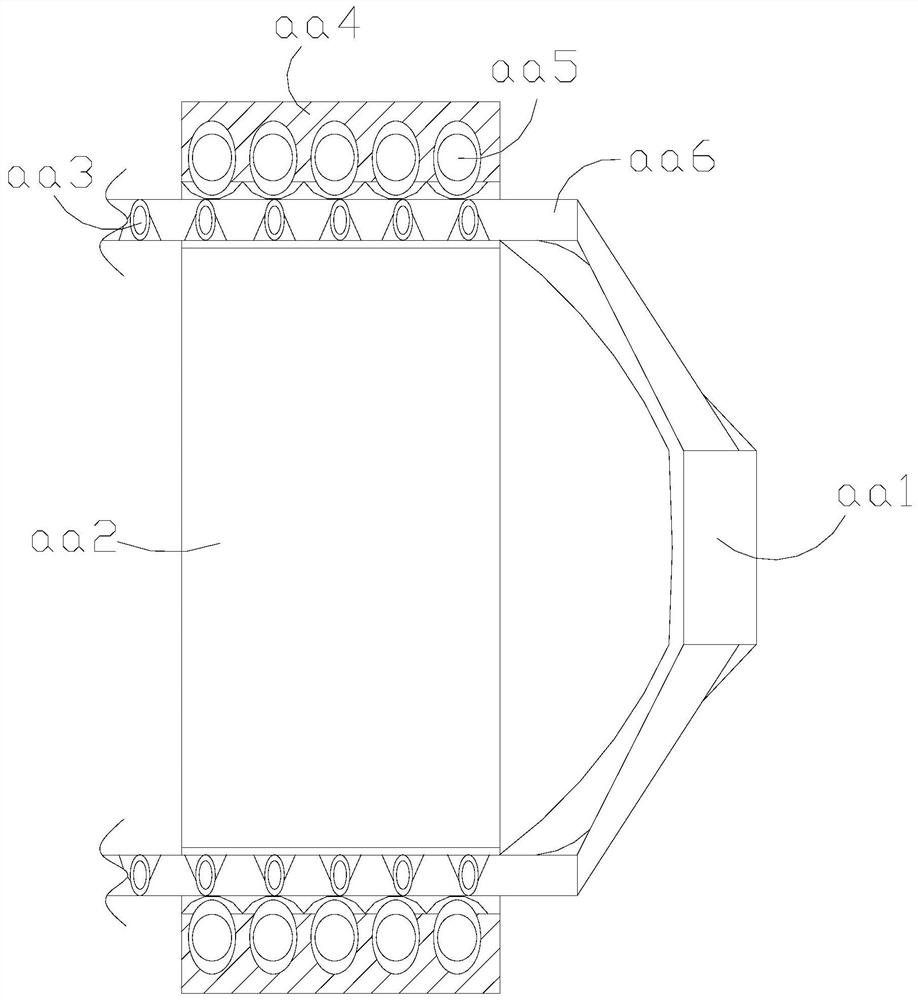

[0031] The forming extrusion hole 44 includes an end cap aa1, an output channel aa2, a stretched top circle aa3, a socket aa4, an ellipsoid aa5, and a sticker aa6. The end cap aa1 is connected with the sticker aa6, and the The output channel aa2 runs through the inside of the bracket aa4 and is located on the same axis, the stretched top circle aa3 is embedded in the inside of the sticker aa6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com