Spray welding wire drawing machine reel with high wear resistance

A wire drawing machine reel, high wear resistance technology, applied in the field of steel wire manufacturing, can solve the problems of easy scaling and muddying of the reel, reducing the heat exchange efficiency of the reel, etc., to ensure the heat exchange efficiency, easy to clean, prolong The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

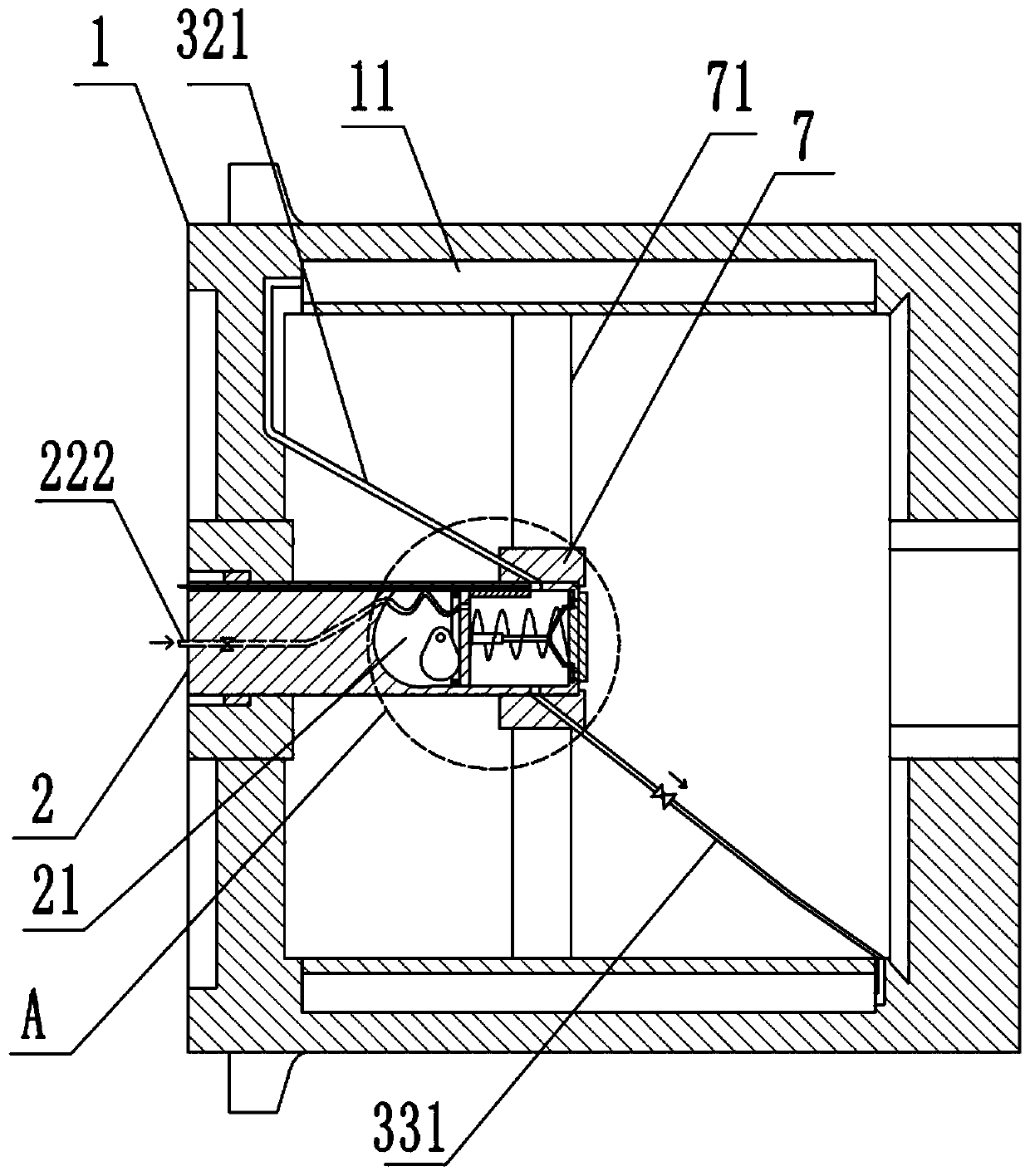

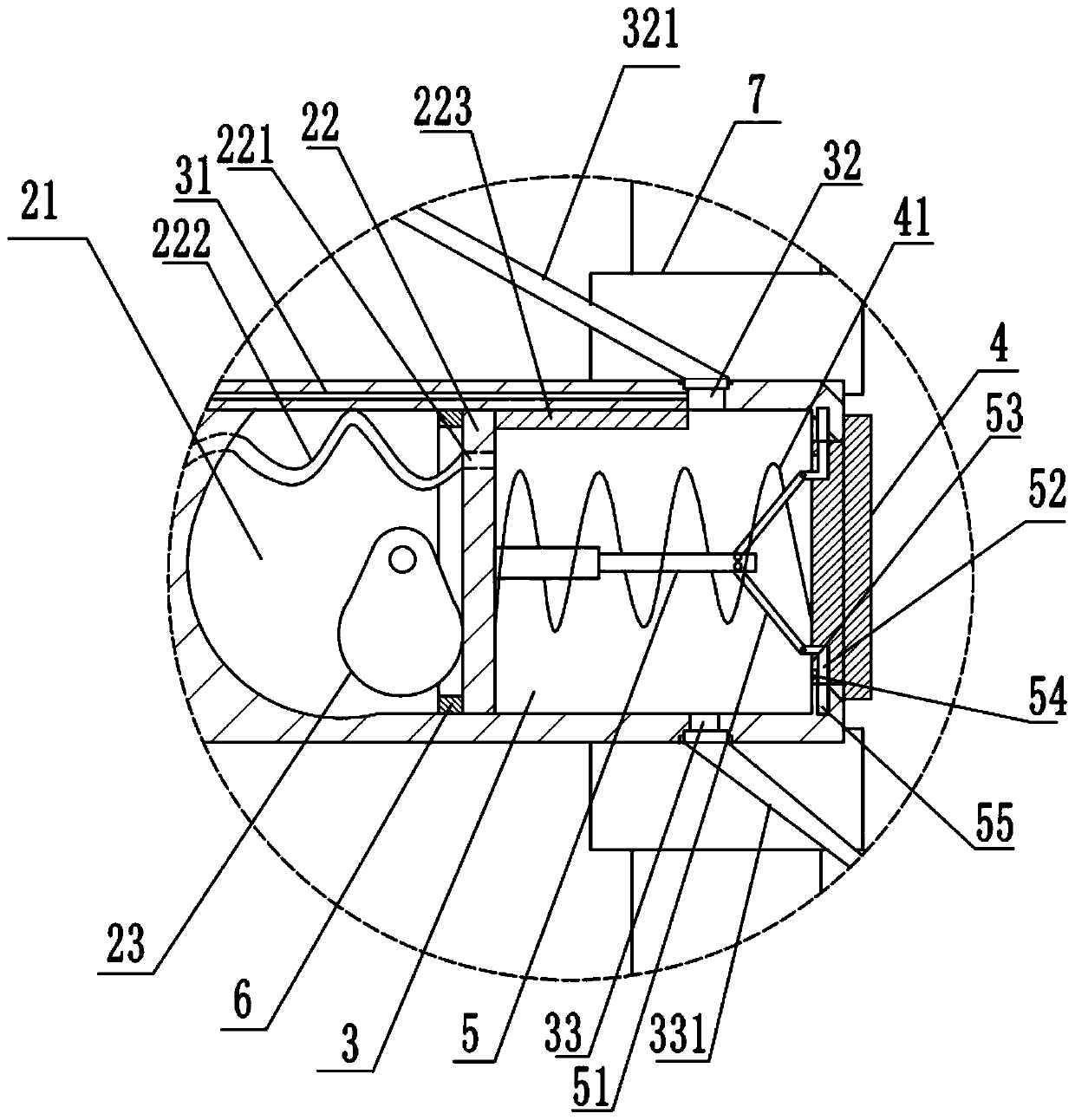

[0029] Basic as attached figure 1 with figure 2 As shown: the reel of the spray welding wire drawing machine with high wear resistance includes a reel body 1, and an annular cavity 11 is provided inside the wall of the reel body 1. There is also a positioning part inside the reel body 1 , the positioning part includes a mounting ring 7 and a support rod 71 , and the support rod 71 is fixed between the mounting ring 7 and the inner wall of the reel body 1 .

[0030] A mounting hole is provided on one side of the reel body 1 , and a columnar cooling part 2 is mounted in the mounting hole, and the end of the cooling part 2 protrudes into the mounting ring 7 . And the connection mode between the installation hole and the cooling part 2 is screw connection.

[0031] A cavity, a piston 22 and a cam 23 for moving the piston 22 are provided inside the cooling part 2 , the piston 22 is slidably connected in the cavity, and the piston 22 separates the cavity into a placement cavity 2...

Embodiment 2

[0044] The difference between this embodiment and the first embodiment is that, in order to facilitate the installation of the cooling part 2, an installation cavity is provided in the outer wall of the cooling part 2, and the motor is fixed in the installation cavity. The connection mode between the installation hole and the cooling part 2 is clamping; the details are as follows: the hole wall of the installation hole is provided with an L-shaped card slot, which specifically includes a vertical slot and a horizontal slot connected with the vertical slot; the cooling part 2 The outer wall is provided with a card protrusion for locking into the card slot; when installing, insert the cooling unit 2 from the installation hole until the card protrusion enters the vertical groove, and when the card protrusion moves to the junction of the vertical groove and the horizontal groove, turn Cooling part 2, so that the card protrusion enters the horizontal groove, that is, the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com