Die-cutting machine used for paper product packaging

A technology for packaging and die-cutting machines, applied in packaging, transportation and packaging, container manufacturing machinery, etc., can solve problems affecting die-cutting efficiency, irregular creasing lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

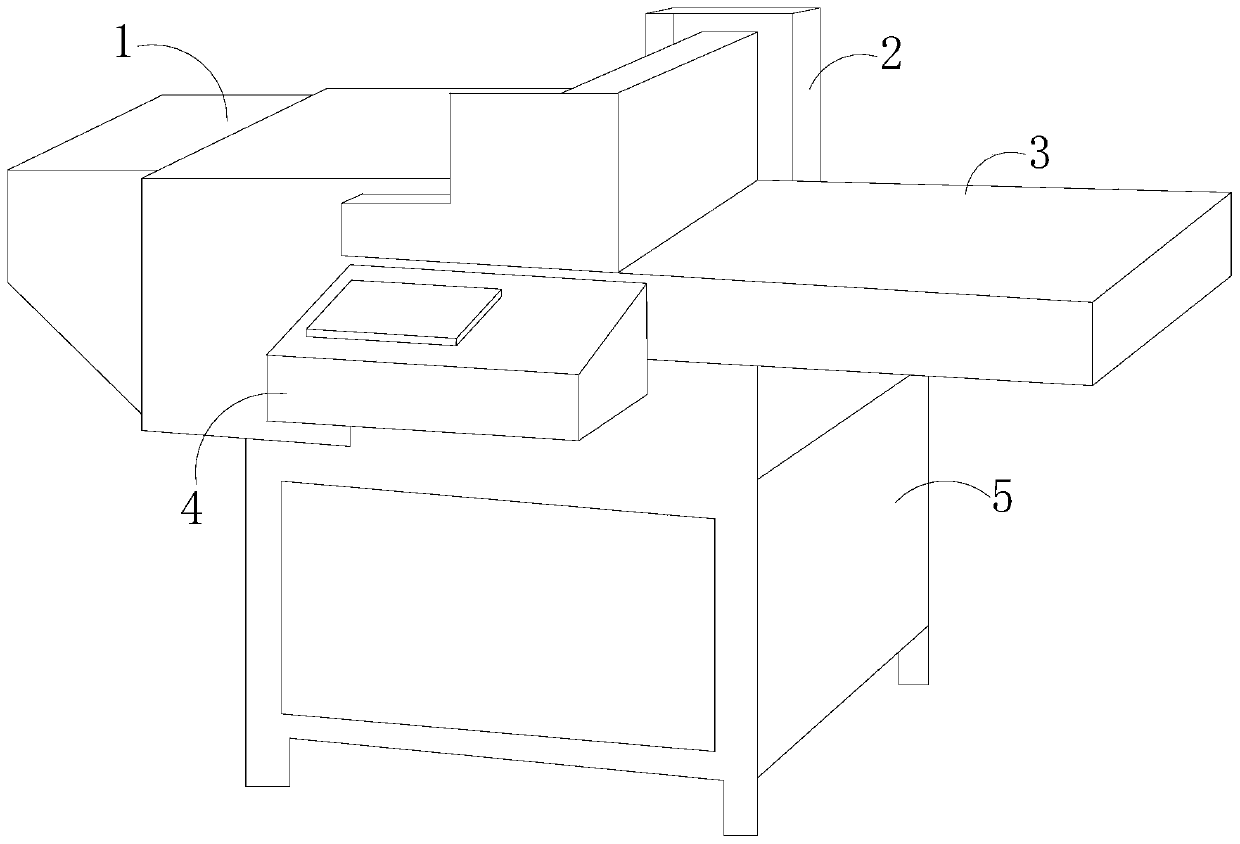

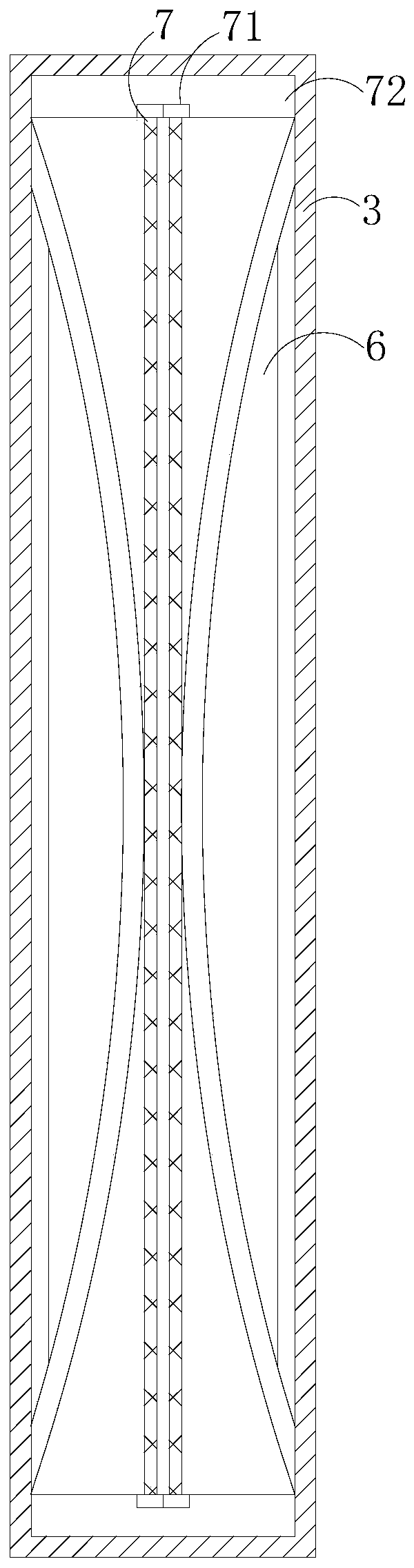

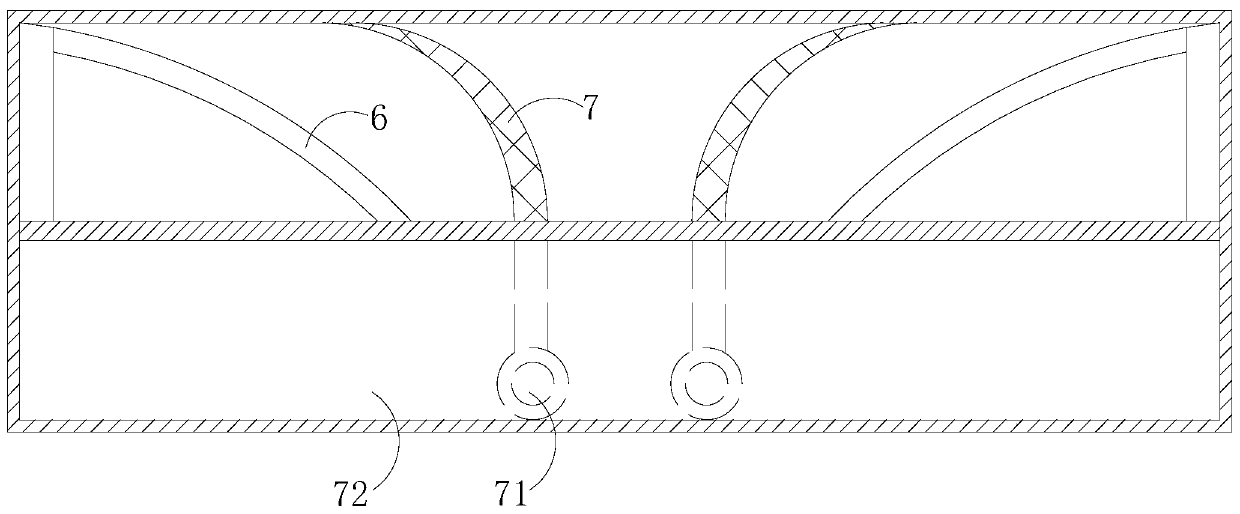

[0030] Such as Figure 1-Figure 7 As shown, the present invention provides a die-cutting machine for paper product packaging. Its structure includes a protective cover 1, a dust-proof baffle 2, a die-cutting base 3, an operation panel 4, and a control host 5. The inside of the die-cutting base 3 A movable sector plate 6 and an indentation plate 7 are provided. The movable sector plate 6 and the indentation plate 7 form an indentation die. The protective cover 1 is arranged on the die-cutting base 3 and is located on the dustproof baffle 2. On the left, the signal terminal inside the die-cutting base 3 is electrically connected to the circuit between the operation panel 4 and the control host 5. The indentation plate 7 is slidably fitted in the guide wheel rail 72 through the movable guide wheel 71. The guide wheel The rails 72 are arranged on both sides of the die-cutting base 3. The indentation plate 7 is provided with two movable grooves that cooperate with each other to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com