Anti-electromagnetic interference wiring harness box

An anti-electromagnetic interference, wire harness technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of inconvenient wire arrangement, poor isolation effect of wire harness boxes, etc., to facilitate the arrangement and reduce workload. , the effect of reducing radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

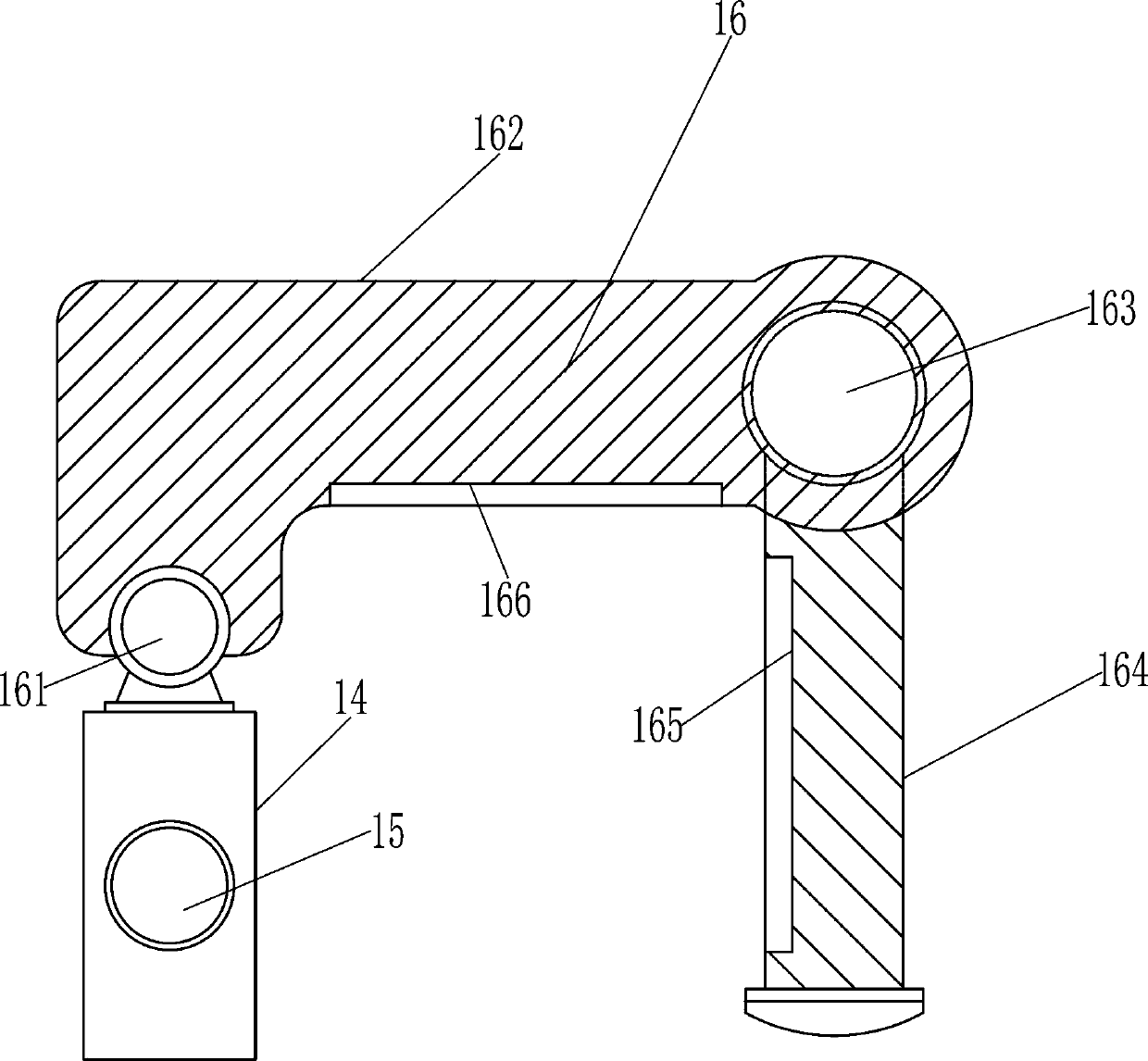

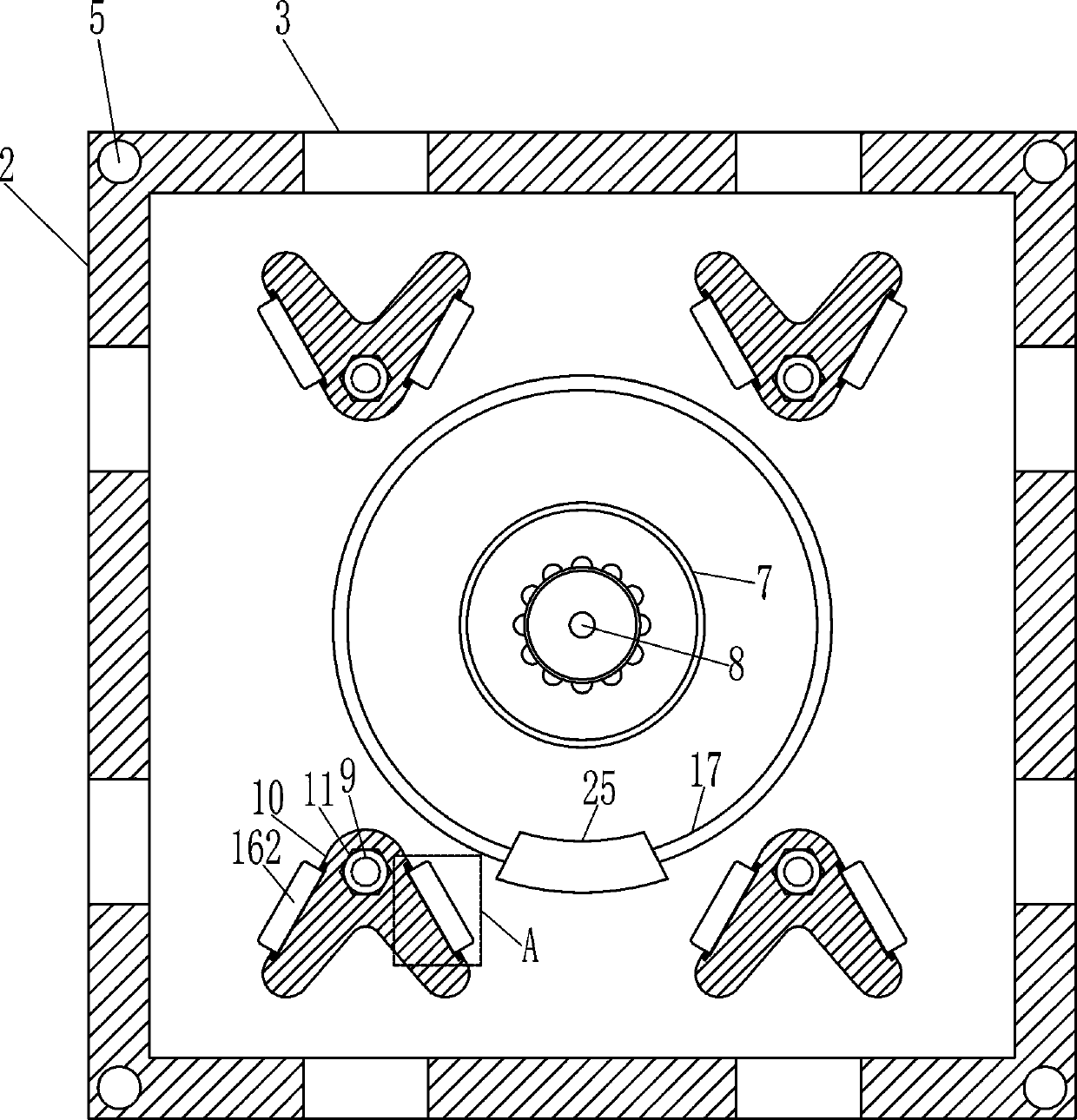

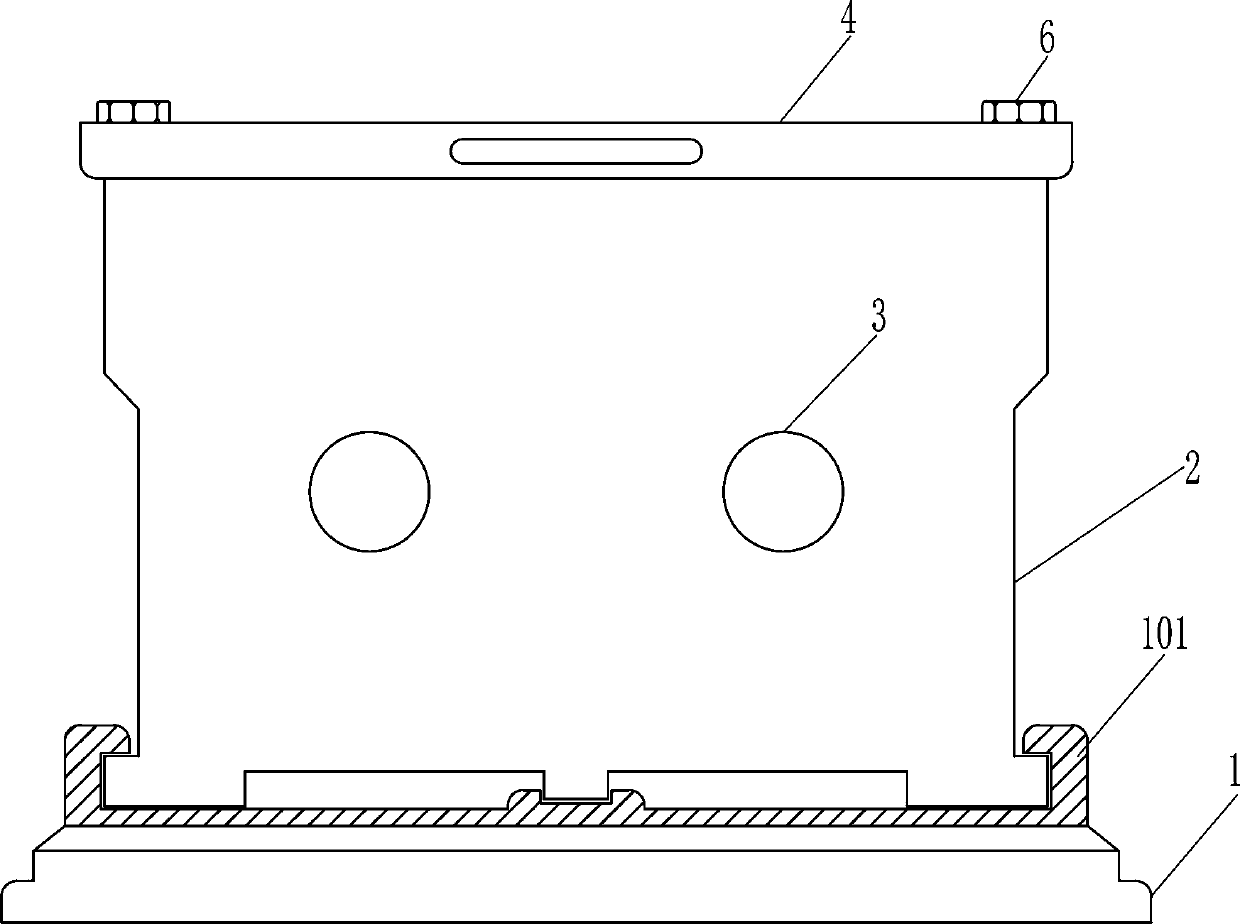

[0019] An anti-electromagnetic interference harness box, such as Figure 1-4 As shown, it includes a base 1, a ferrule 101, a box body 2, a cover plate 4, a first bolt 6, a first winding reel 7, a turntable 8, an arc plate 10, a second bolt 11, a placement plate 14, and a Rod 15 and wire harness 16, the top of the base 1 is equipped with a ferrule 101 that can be fixed to the box body 2, the base 1 is connected to the ferrule 101 by welding, the ferrule 101 is provided with a sliding box body 2, the box There are two inlet holes 3 on the front, rear, left, and right sides of the body 2, a cover plate 4 is placed on the top of the box body 2, and a first threaded hole 5 is opened on the front, rear, left, and right sides of the top of the box body 2, and the top of the cover plate 4 There are also first threaded holes 5 on the front, back, left, and right sides of the front and back, and the first bolts 6 for fixing are arranged between the upper and lower two adjacent first th...

Embodiment 2

[0021] An anti-electromagnetic interference harness box, such as Figure 1-4 As shown, it includes a base 1, a ferrule 101, a box body 2, a cover plate 4, a first bolt 6, a first winding reel 7, a turntable 8, an arc plate 10, a second bolt 11, a placement plate 14, and a Rod 15 and harness device 16, the ferrule 101 that can be fixed to box body 2 is installed on the top of base 1, is provided with sliding type box body 2 in ferrule 101, and box body 2 is provided with two inlets on the front, rear, left, and right sides. Wire hole 3, cover plate 4 is placed on the top of box body 2, the first threaded hole 5 is all opened on the front, rear, left, and right sides of the top of box body 2, and the first threaded hole is also all opened on the front, rear, left, and right sides of the top of cover plate 4 5. There is a first bolt 6 for fixing between the upper and lower two adjacent first threaded holes 5, and the first winding reel 7 that can wind the wire is rotatably connec...

Embodiment 3

[0024] An anti-electromagnetic interference harness box, such as Figure 1-5 As shown, it includes a base 1, a ferrule 101, a box body 2, a cover plate 4, a first bolt 6, a first winding reel 7, a turntable 8, an arc plate 10, a second bolt 11, a placement plate 14, and a Rod 15 and harness device 16, the ferrule 101 that can be fixed to box body 2 is installed on the top of base 1, is provided with sliding type box body 2 in ferrule 101, and box body 2 is provided with two inlets on the front, rear, left, and right sides. Wire hole 3, cover plate 4 is placed on the top of box body 2, the first threaded hole 5 is all opened on the front, rear, left, and right sides of the top of box body 2, and the first threaded hole is also all opened on the front, rear, left, and right sides of the top of cover plate 4 5. There is a first bolt 6 for fixing between the upper and lower two adjacent first threaded holes 5, and the first winding reel 7 that can wind the wire is rotatably connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com