The construction method suitable for the secondary restoration of the ore-drawing system of the deep-large chute

A technology of deep and large sliding wells and construction methods, which is applied in mining equipment, earth-moving drilling, vertical shaft equipment, etc. Reasonable and shortened repair period effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

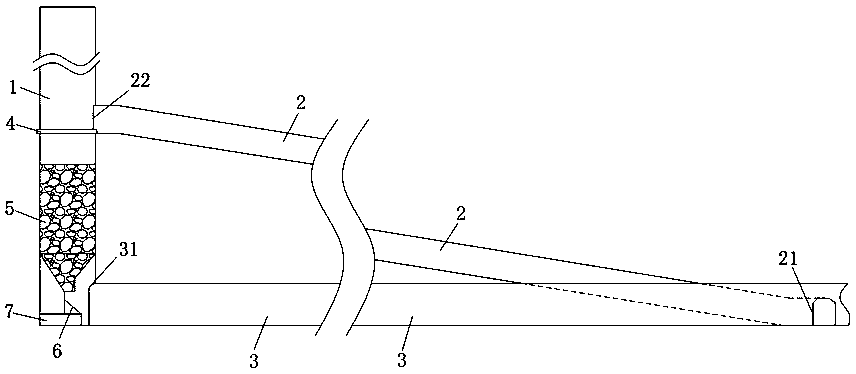

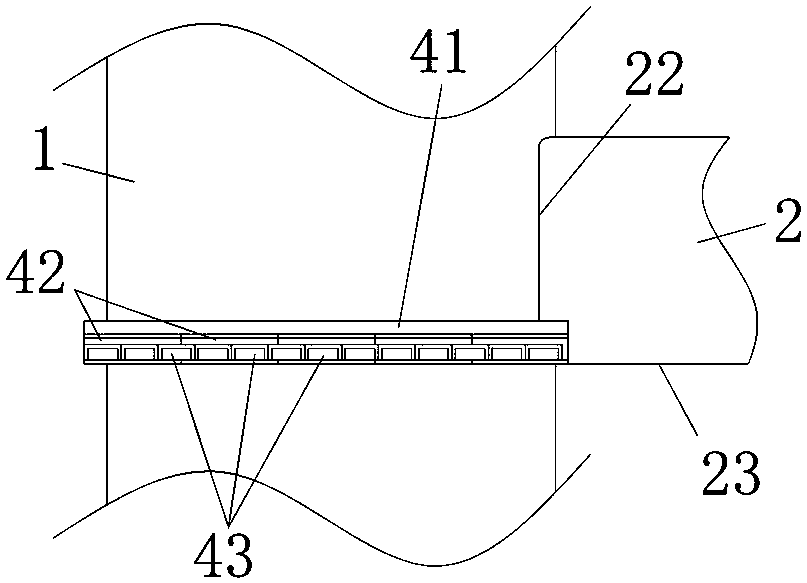

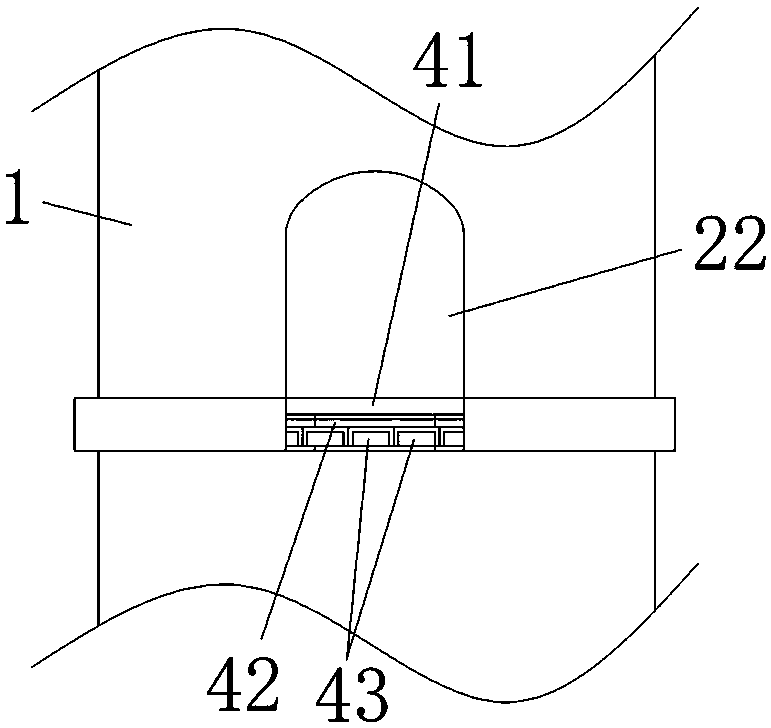

[0035] Such as Figure 1-8 As shown, the present invention is applicable to a construction method for the secondary repair of the ore-drawing system of the deep-large chute, comprising the following steps:

[0036] Step S1: Use the method of rock drilling and blasting to dig a ramp from the transportation roadway 3 as the measure lane 2; the slope of the measure lane 2 is 16%, and the exit 22 of the measure lane 2 is set at 2m above the ore storage section of the chute , to prevent high-altitude operations and reduce the engineering volume of the measure lane; leave a 5m horizontal section 23 at the exit 22 of the measure lane for temporary placement of materials and equipment;

[0037] Step S2: Drilling rock with a pneumatic pick, starting from the two corners at the exit 22 of the measure lane, and horizontally excavating a section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com