Sliding plate valve structure

A technology for slide valves and plate valves, applied in slide valves, valve devices, engine components, etc., can solve problems such as fluid leakage and poor durability of slide valves, and achieve low cost, simple and fast installation methods, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

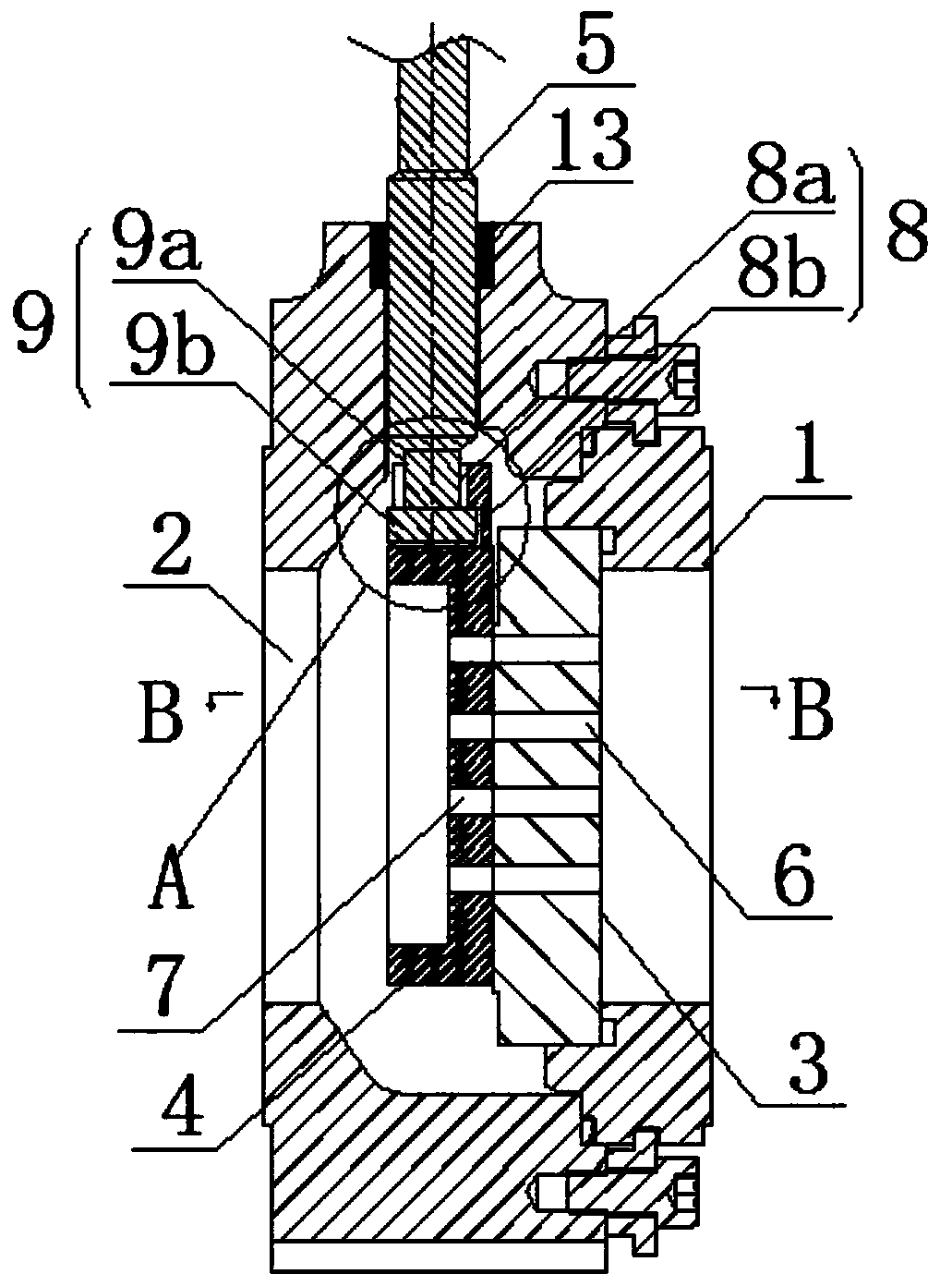

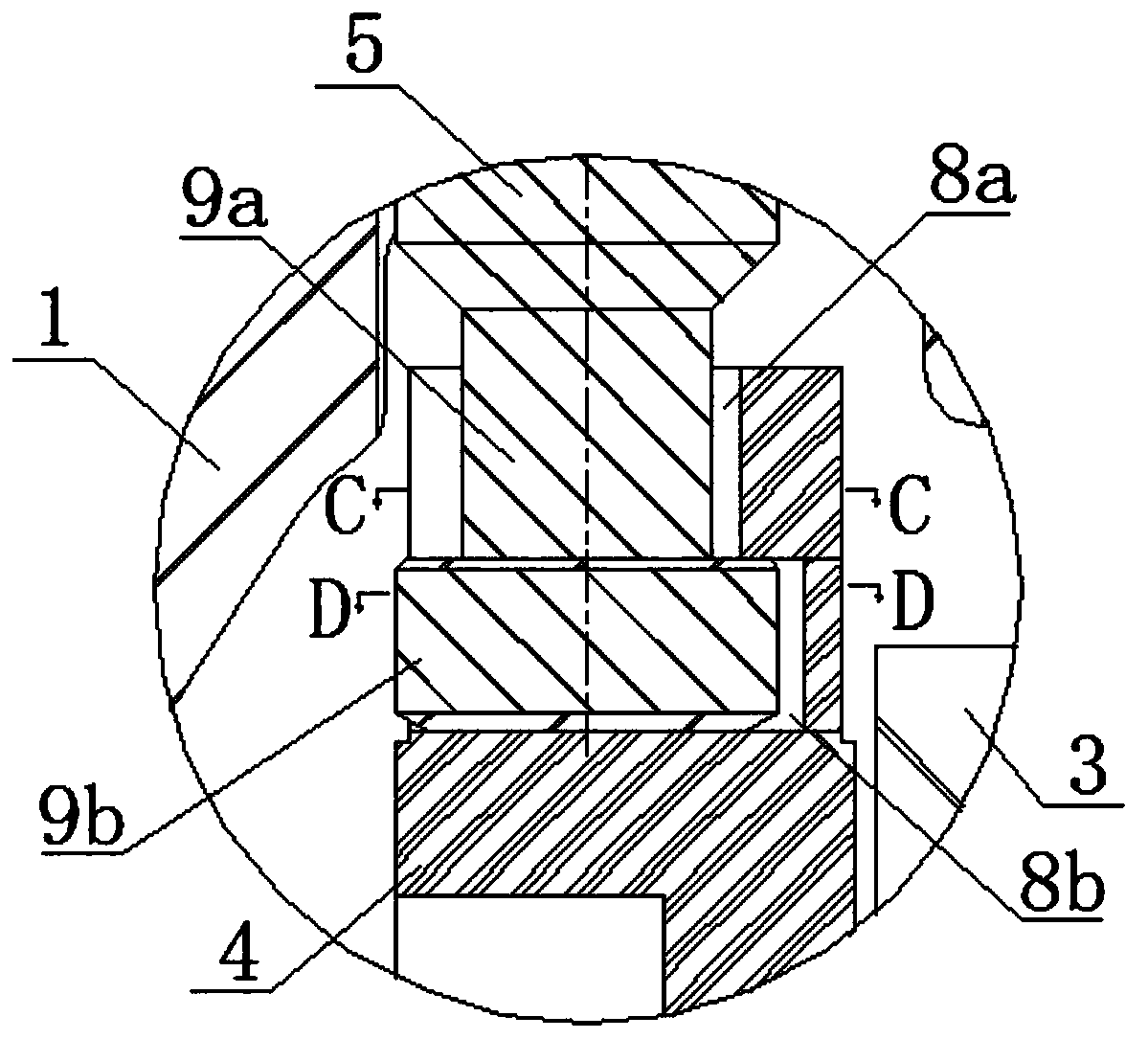

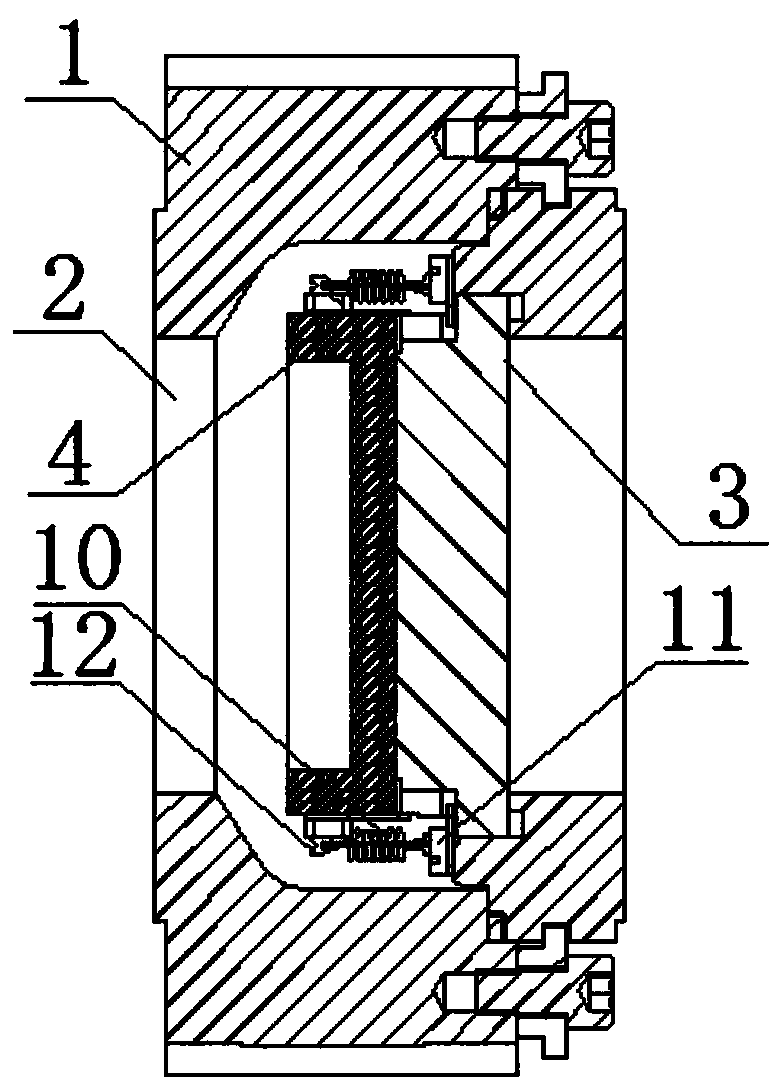

[0035] like Figure 1-Figure 3Shown: a slide valve structure, which is composed of a valve body 1, a flow channel 2, a plate valve seat 3, a plate valve core 4 and a valve stem 5, the flow channel 2 is arranged transversely and runs through the valve body 1, the The valve seat 3 is set in the flow channel 2 and is perpendicular to the flow direction of the medium. The edge of the valve seat 3 is sealed with the inner wall of the flow chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com