Golf club shaft having wave shaped reinforced part and making method thereof

A golf ball and wave-shaped technology, applied to golf balls, golf clubs, rackets, etc., can solve the problems of reduced flexural strength, complicated manufacturing process, increased flight distance, etc., and achieve the effect of improving twist characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

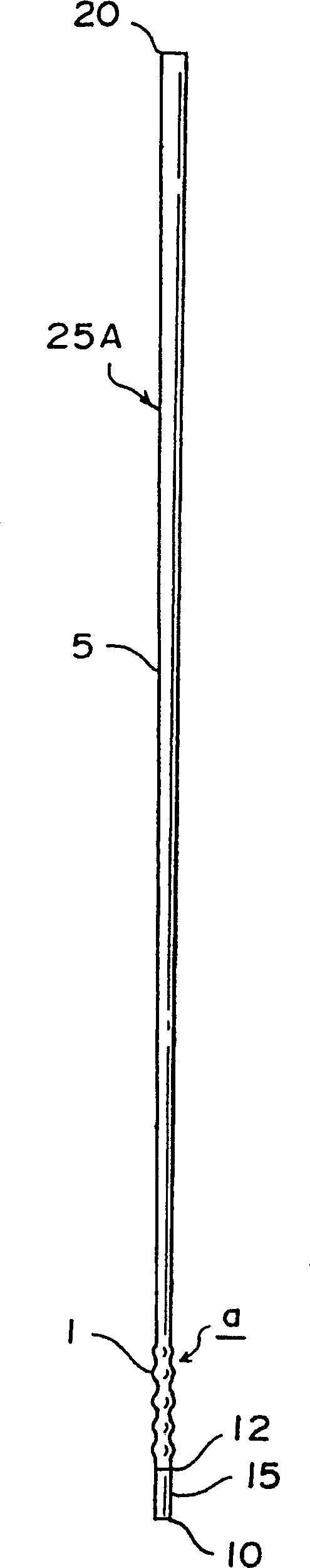

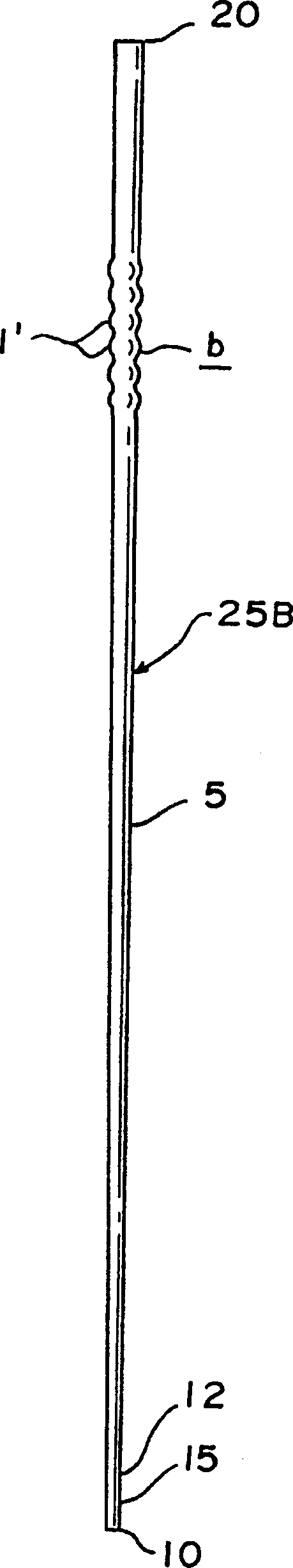

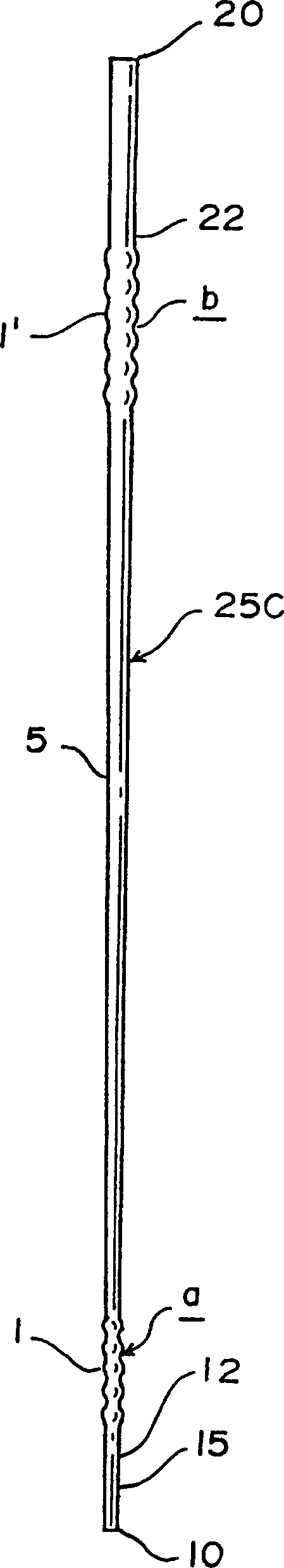

[0032] figure 1 A first embodiment of the golf club shaft 25A of the present invention is shown in which the wave-shaped reinforcing portion 1 is formed at the lower portion of the golf club shaft. The lower part of the rod is located between the midpoint of the entire length of the rod and the upper end 12 of the sleeve part. figure 1 A preferred position a of the reinforcement close to the sleeve part 15 is shown. Of course, the corrugated part 1 can be located at other positions between the upper end of the sleeve part and the midpoint of the lower part of the rod. When the wave-shaped reinforcing part 1 is located at the position a of the base shaft 5, the flexing characteristics of the golf club shaft are significantly improved.

[0033] The wave-shaped reinforced portion of the golf club shaft of the present invention is composed of reinforced segments. In the wave-shaped reinforced part 1, the number of reinforcing segments is 1-6 segments, preferably 1-3 segments. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com