Substrate detection device

A substrate detection and sliding plate technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of increasing acuity, inability to provide, clear visual environment, etc., to achieve easy observation, improve visual comfort, and clear visual environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

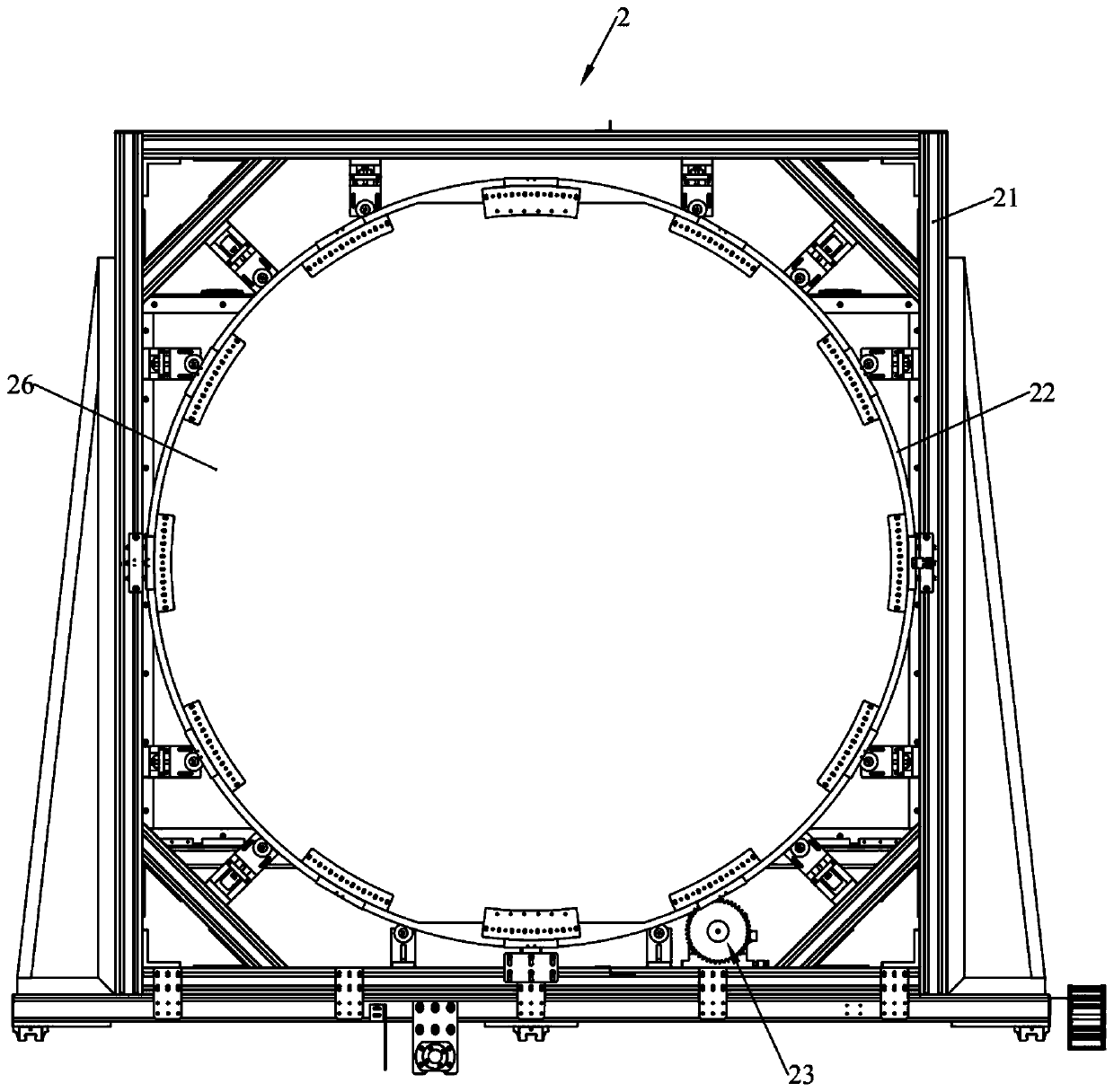

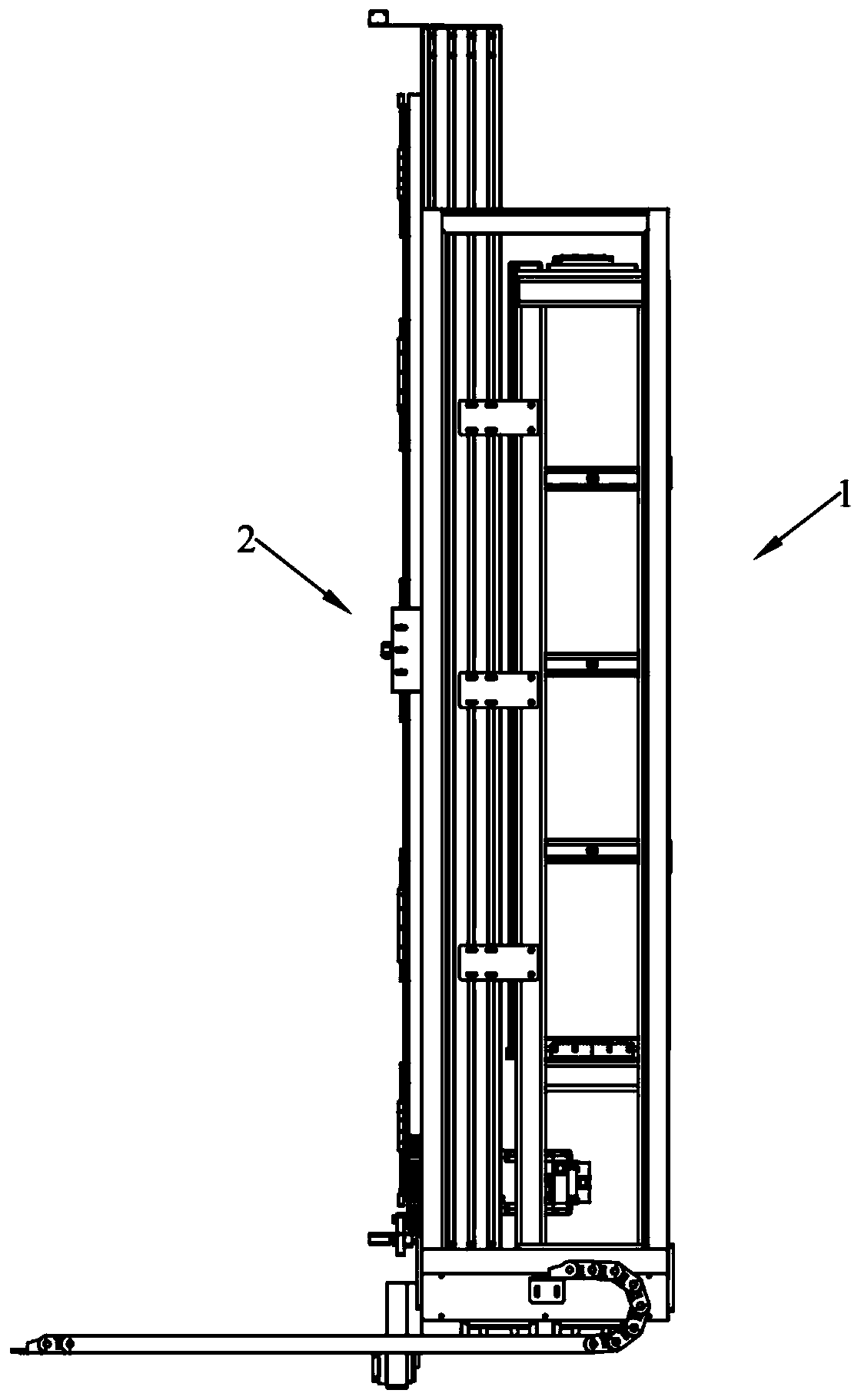

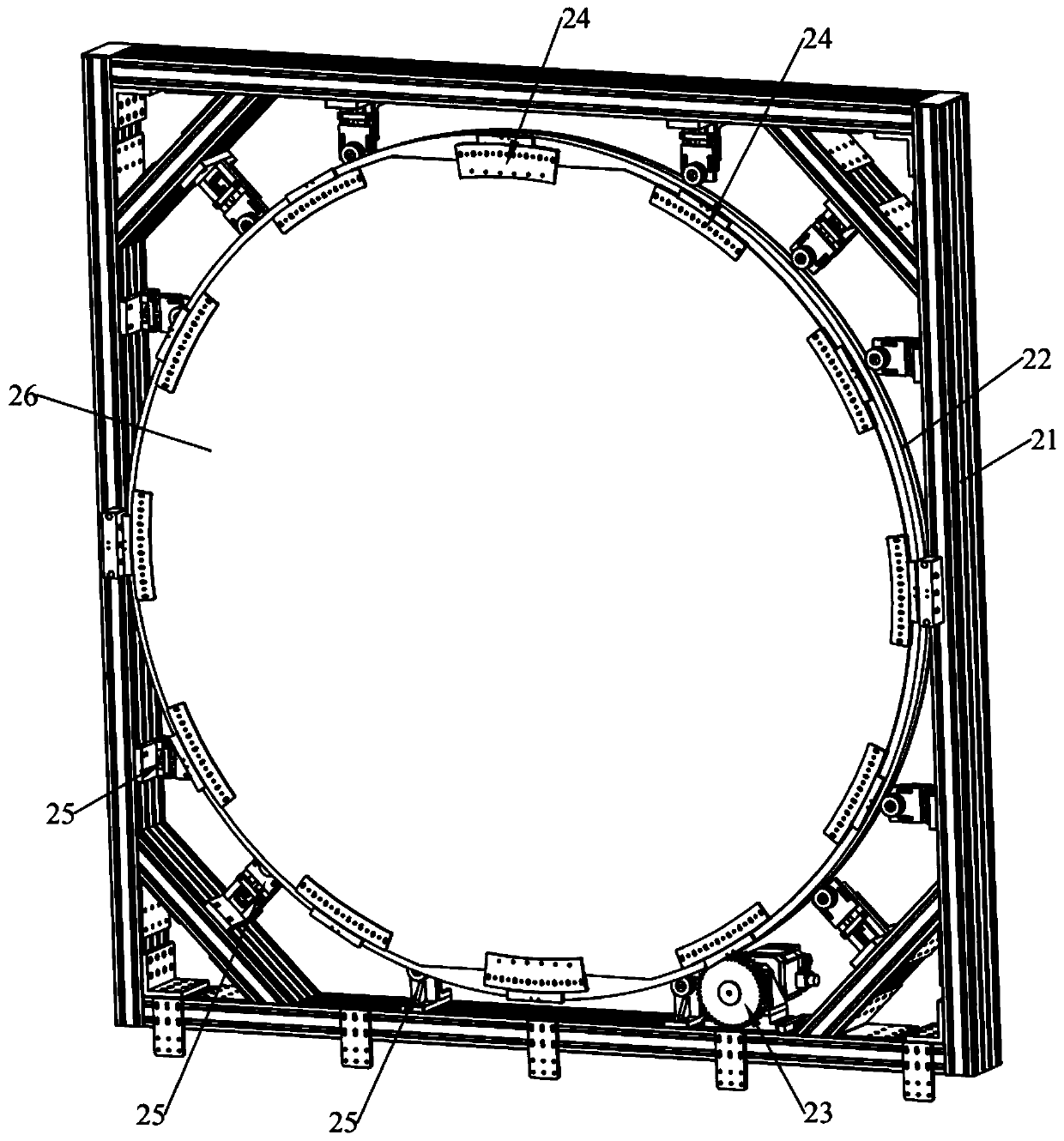

[0040] The invention provides a substrate detection device, such as figure 1 and figure 2 As shown, the substrate inspection device includes a backlight box assembly 1 through which a backlight is emitted, and the backlight is irradiated onto the substrate to be inspected, and inspectors detect defects on the substrate by observing the substrate.

[0041] Since the transparent acrylic on the back light box does not have the functions of filtering stray light, increasing sensitivity, etc., and cannot provide a clearer visual environment, too long observation time may easily cause discomfort or visual fatigue to the inspectors.

[0042] In order to solve the above problems, the substrate detection device provided by the present invention also includes a polarizer assembly 2, such as figure 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com