High-performance heat-resistant mineral fireproof cable

A fire-resistant cable and mineral technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of poor compressive performance of fire-resistant cables, achieve poor compressive performance, simple structure, and improve compressive capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

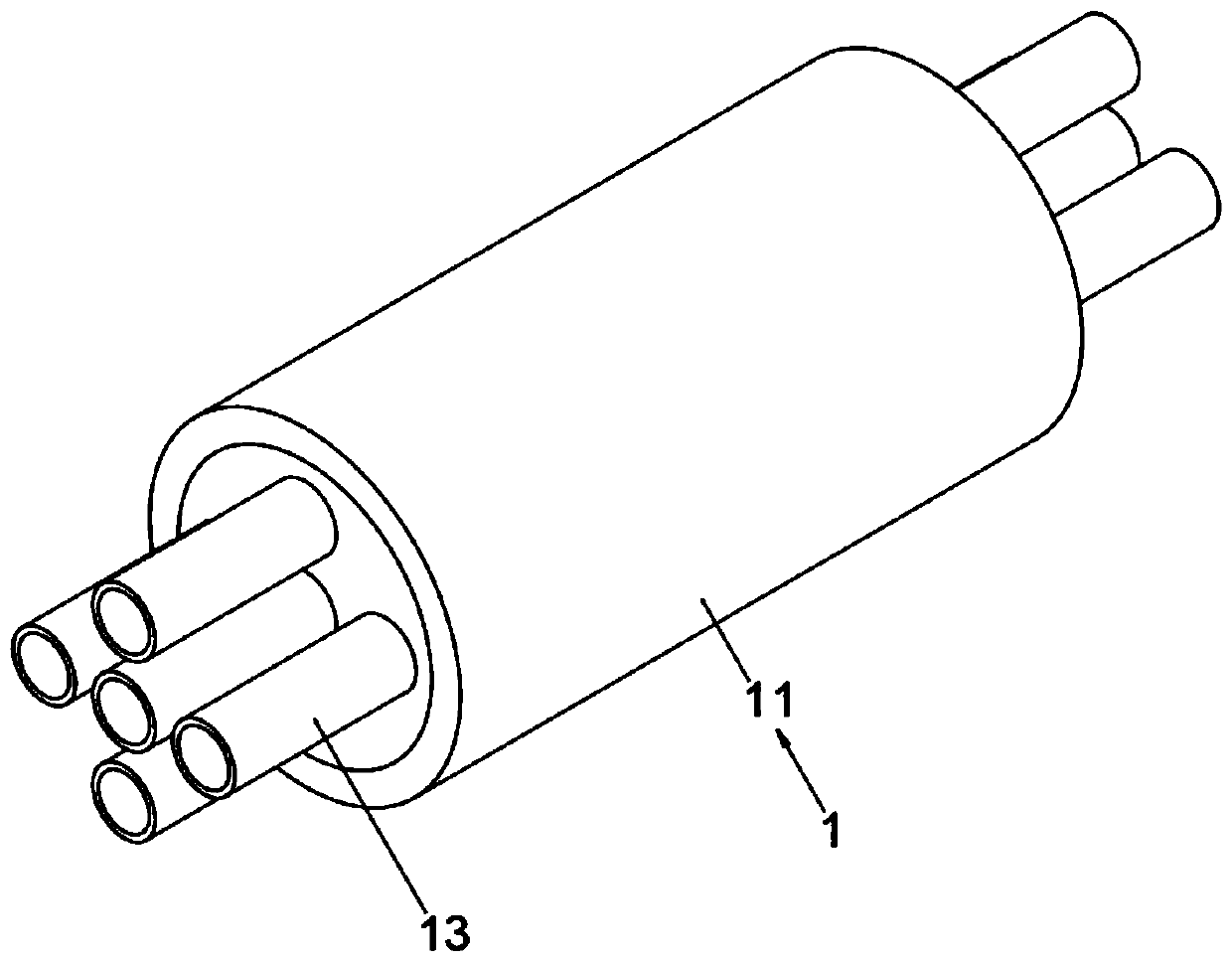

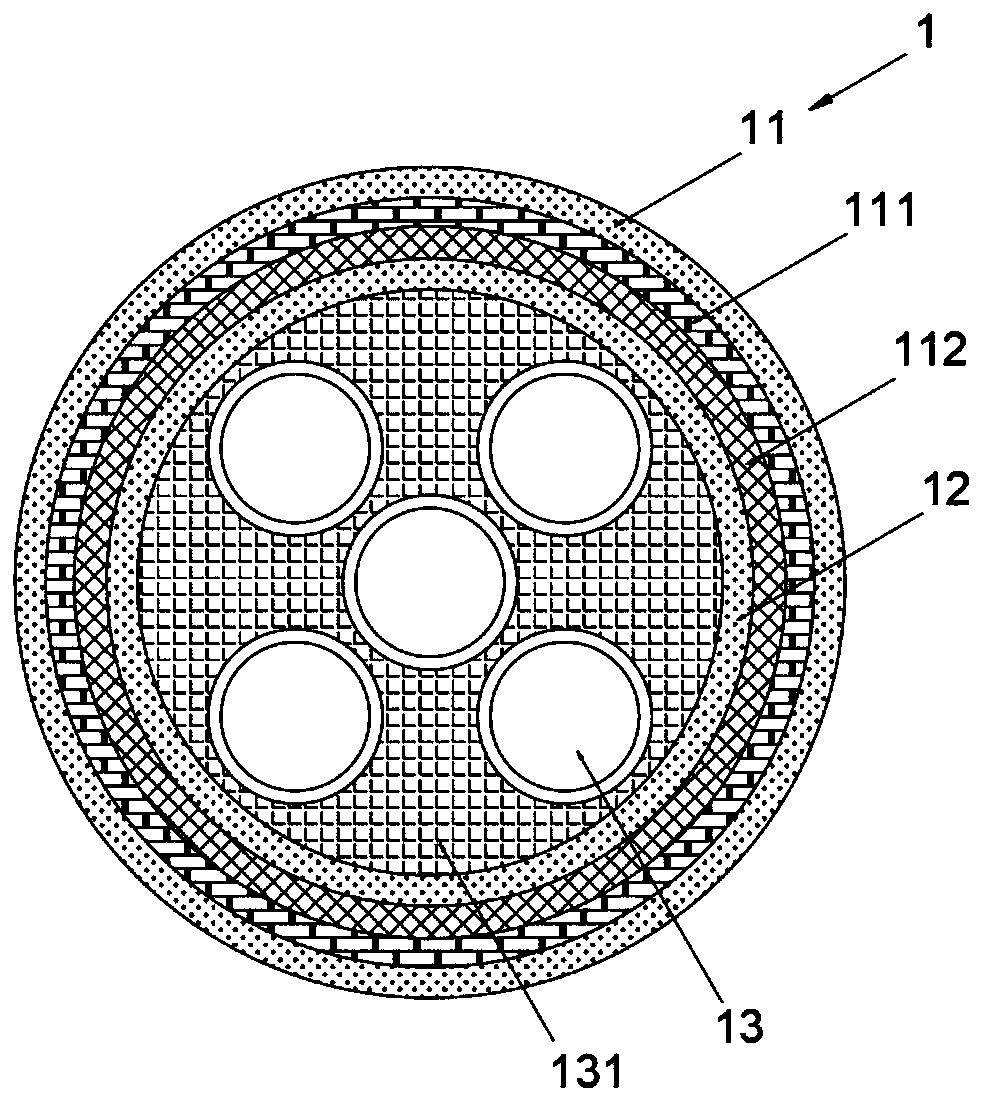

[0031] A high-performance heat-resistant mineral fire-resistant cable, such as Figure 1-3 As shown, it includes a cable body 1, the cable body 1 includes an outer insulating layer 11, an inner insulating layer 12 and several cable cores 13, and a heat-resistant layer 111 and a steel wire mesh are tightly bonded between the outer insulating layer 11 and the inner insulating layer 12 layer 112 , the cable core 13 is located within the inner insulating layer 12 .

[0032] In this embodiment, the outer insulating layer 11 and the inner insulating layer 12 are all made of PVC (polyvinyl chloride) material, which has good wear resistance and corrosion resistance, and has better insulation and toughness, and lower cost. Advantages, prolong its service life.

[0033] Furthermore, the heat-resistant layer 111 is made of mineral fiber material, which has good heat insulation and fire prevention effects, and has the advantages of a stable structure and is not easy to crack, so as to im...

Embodiment 2

[0038] As a second preferred embodiment of the present invention, a filling rubber 131 is provided between the cable core 13 and the inner insulating layer 12 , so that the filling rubber 131 can play a role of shock absorption and compression resistance on the cable core 13 .

Embodiment 3

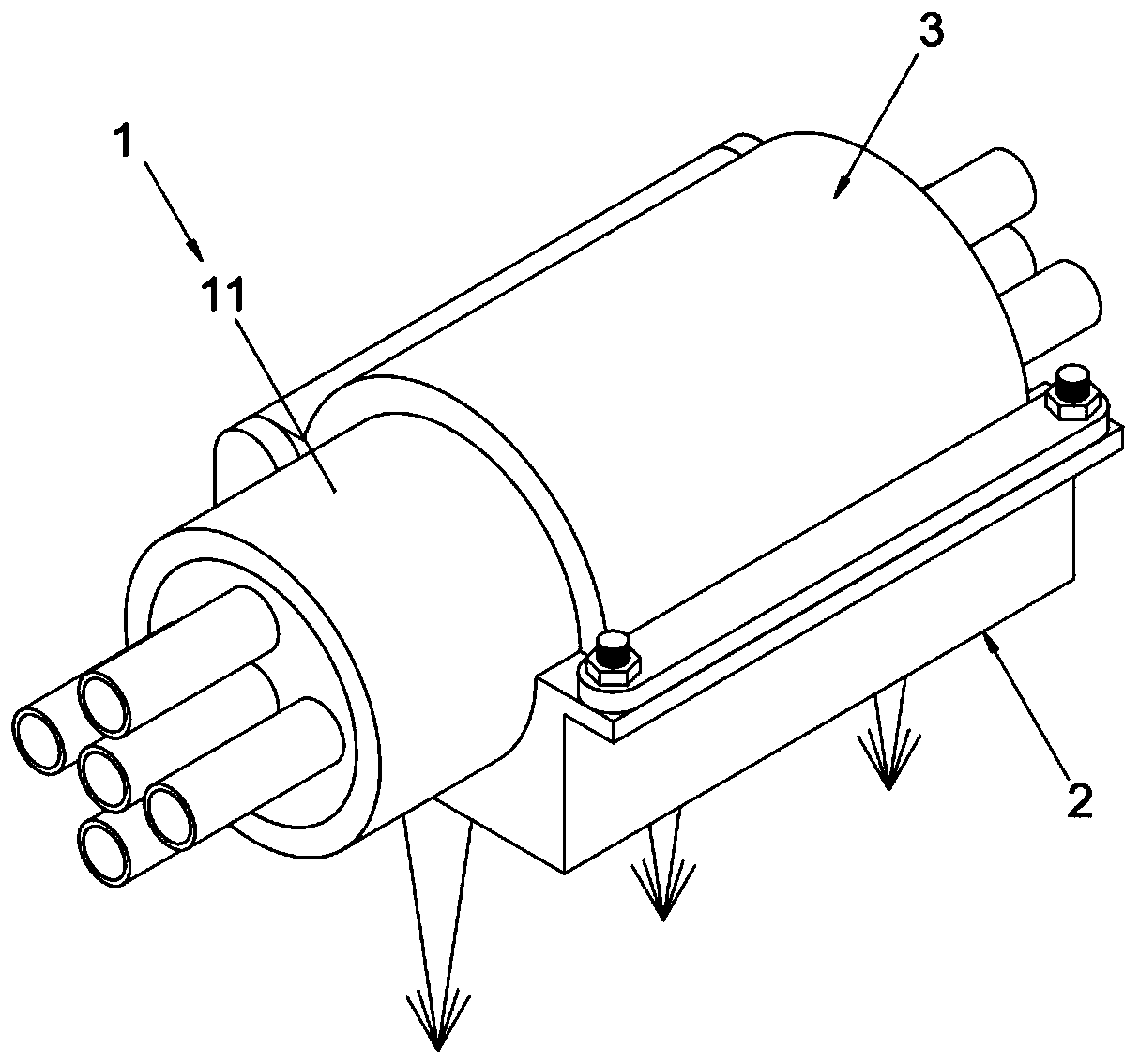

[0040] As the third preferred embodiment of the present invention, such as Figure 4-6 As shown, the cable body 1 is provided with a base 2, the upper surface of the base 2 is provided with a groove 21, and both ends of one side of the base 2 are tightly welded with fixing blocks 22, and the two fixing blocks 22 are tightly welded There is a rotating shaft 221, the other side of the base 2 is tightly welded with a baffle 23, the two ends of the upper surface of the baffle 23 are tightly welded with a screw 231, the screw 231 is provided with a nut 24, and the base 2 is provided with an arched cover Plate 3, one side of the arched cover plate 3 is tightly welded with a connector 31, the connector 31 is provided with a through hole 311, the other side of the arched cover plate 3 is tightly welded with a limiting plate 32, and the two sides of the limiting plate 32 Each end is provided with a round hole 321.

[0041]In this embodiment, the base 2 and the arched cover 3 are all m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com