Inflation heat sealing device

A heat-sealing device and film-laying technology, which is used in transportation and packaging, winding strips, and thin material processing, etc., can solve the problem that the tension of the roll film cannot be guaranteed to be consistent, and achieve the effect of convenient film penetration and good running effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

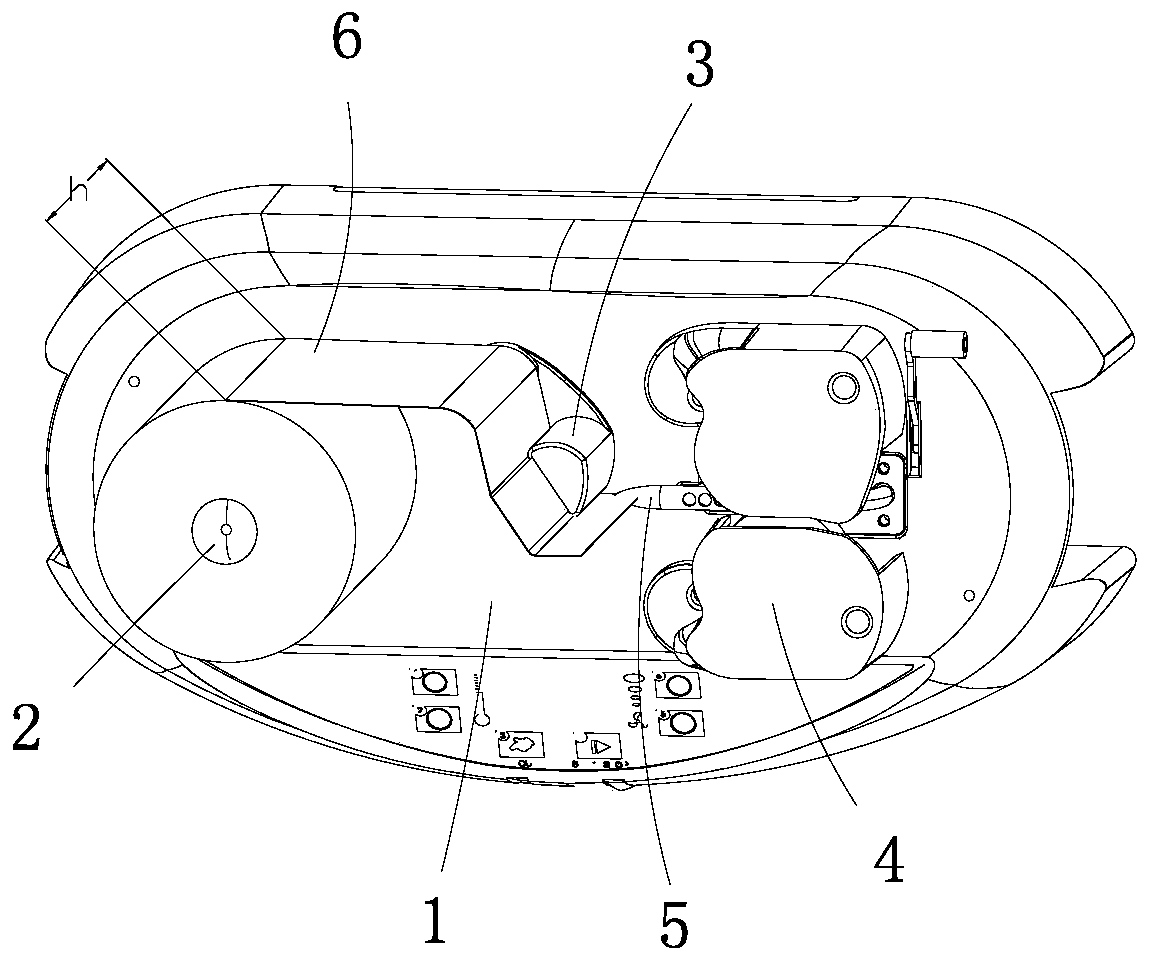

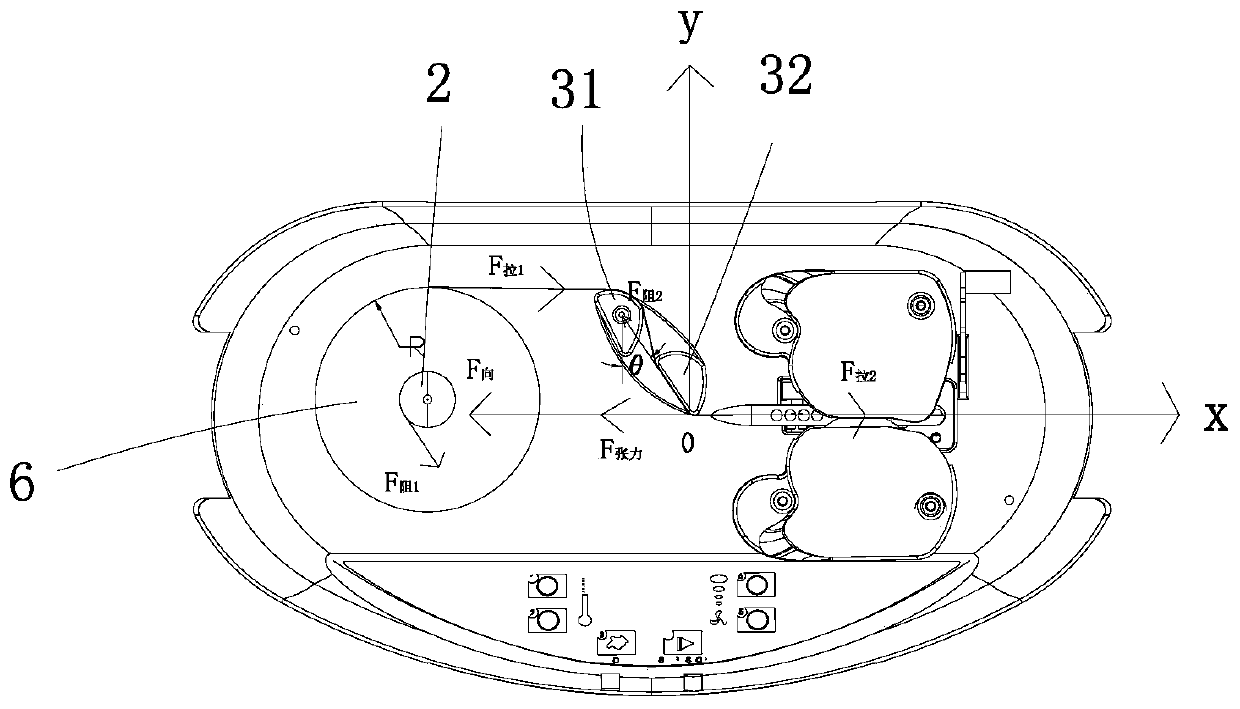

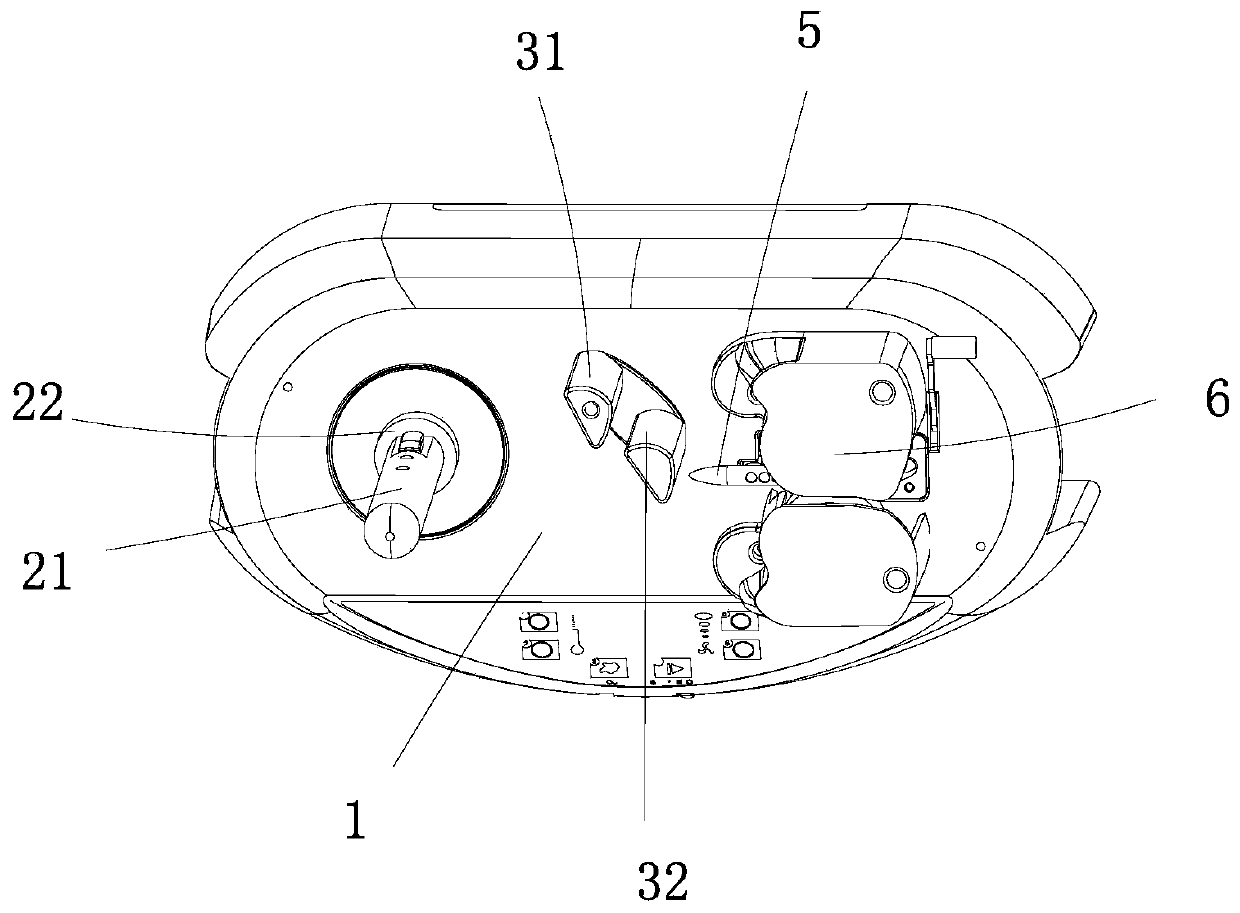

[0040] see Figure 1 to Figure 8 , an inflatable heat-sealing device, comprising a film setting rod assembly 2 and a film transmission assembly 4 arranged on a substrate 1, a film guide assembly 3 is arranged between the film placement rod assembly 2 and the film transmission assembly 4, and the film guide assembly 3 includes a film guide rod. The roll film 6 sleeved on the film rod assembly 2 is conveyed by the film transmission assembly 4 after passing through the film guide rod assembly. The roll film 6 on the film rod assembly 2 is from large roll to small roll During the change process, the film guide rod rotates with the change of the roll film 6 to adjust the force on the film, so that the pulling force F of the film transmission assembly 4 on the film 拉2 Under the condition of constant, the film is always conveyed at a constant speed.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com