Processing method of solid-wood composite floor, solid-wood composite floor and mold

A solid wood composite flooring and solid wood composite technology, applied in the field of home decoration, can solve the problems of cutting, affecting the appearance of solid wood composite flooring, reducing the service life of solid wood composite flooring, etc., and achieve the effect of good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

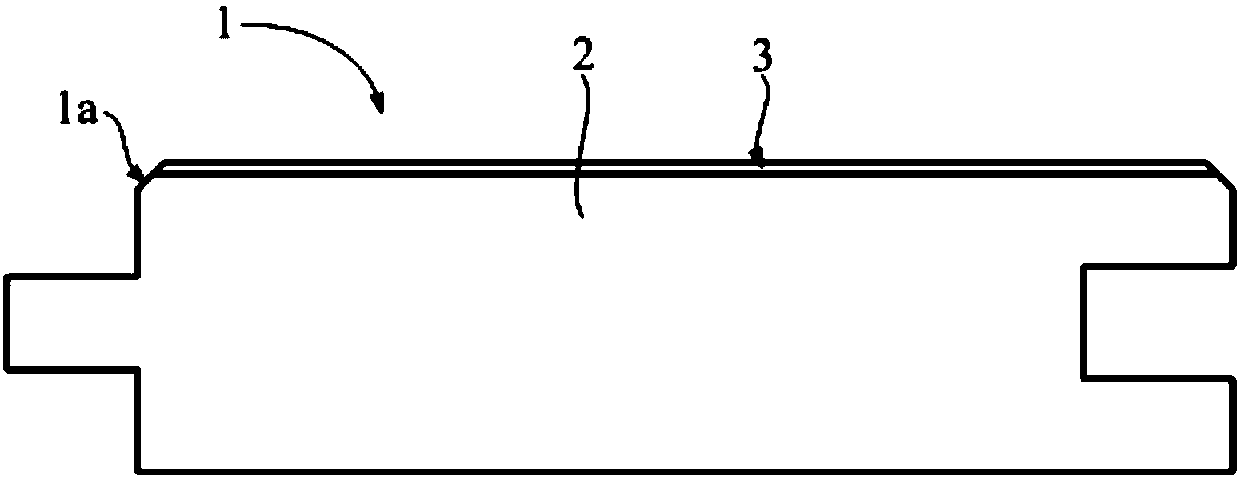

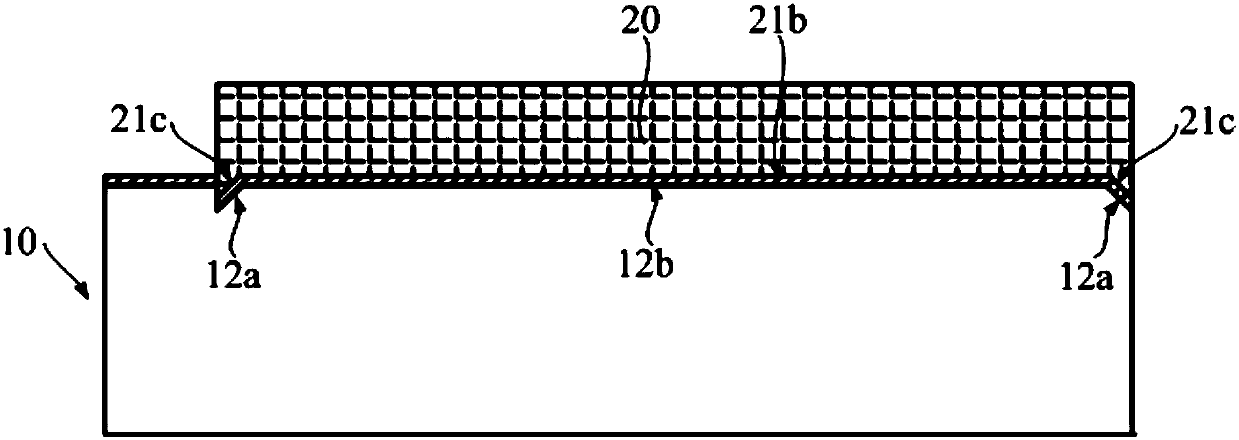

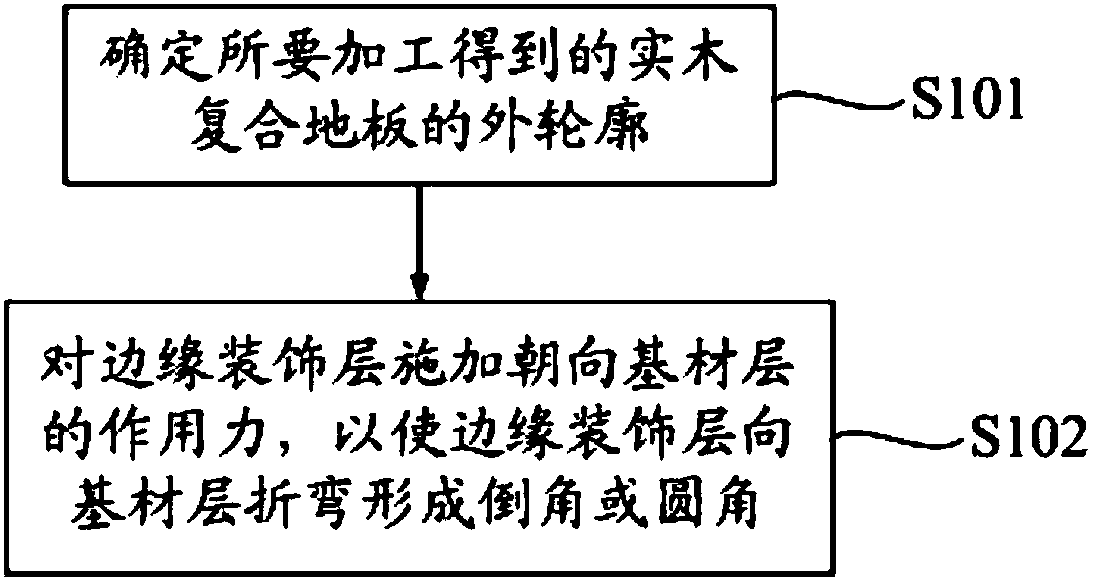

[0036] refer to figure 1 A solid wood composite flooring 1 in the prior art includes a base material layer 2 and a decoration layer 3 , and the decoration layer 3 is fixedly arranged on the upper surface of the base material layer 2 . When the solid wood composite floor 1 is laid on the ground, the decorative layer 3 is the surface of the floor, and the human body is suitable for walking on the decorative layer 3 . Since the decorative layer 3 forms the surface of the floor, relatively high-quality wood will be selected to retain the beautiful and natural characteristics of the wood grain of the solid wood floor. The base material layer 2 is located under the decoration layer 3 and is not easy to be noticed by the human body. Its main function is to make the solid wood composite floor 1 have a stable structure and prevent deformation. Therefore, the materials selected for the decoration layer 3 and the base layer 2 are different.

[0037] In the prior art, in order to make t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com