Self-tightening bolt and nut tightening assembly

A technology for fastening components, bolts and nuts, applied to threaded fasteners, locking fasteners, nuts, etc., can solve the problems of easy loosening and displacement, and achieve the effect of loosening and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

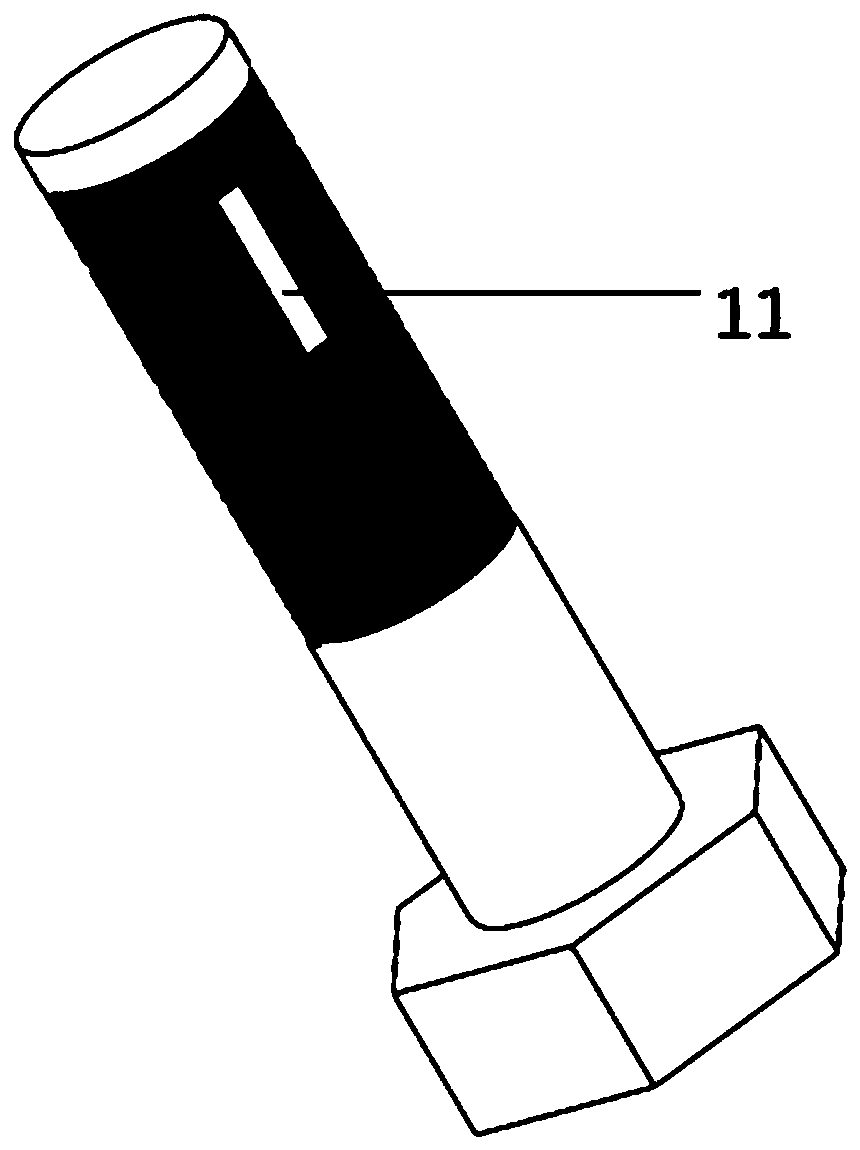

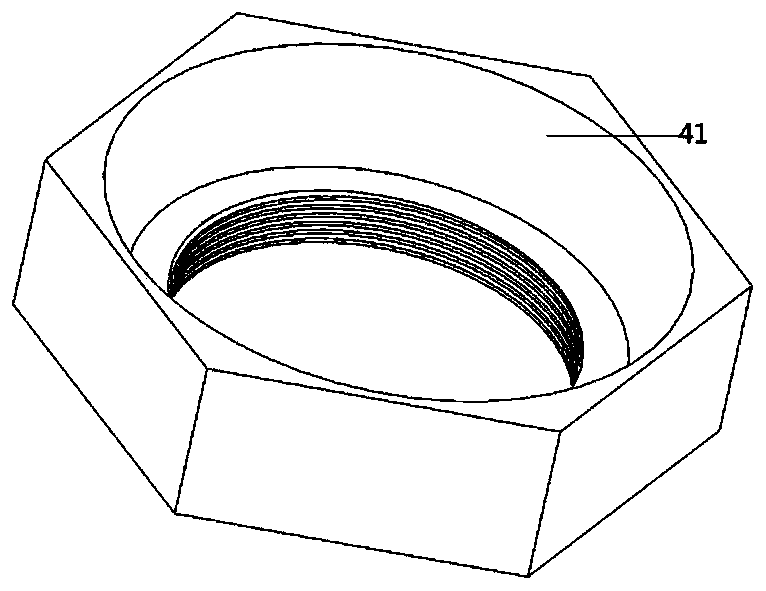

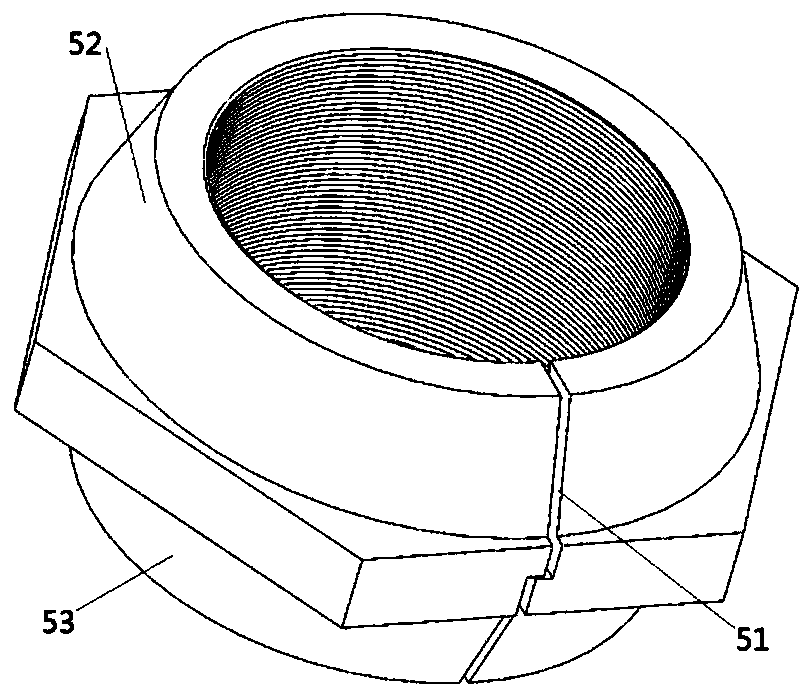

[0027] like figure 1 —7, the present invention provides a self-tightening bolt and nut fastening assembly, including a bolt 1 and an upper nut 4, a self-tightening nut 5, a lower nut 6, a self-locking washer 7, and an end nut 8 that are sequentially connected and matched; the bolt 1 is Hexagon head bolts, including the head and the screw rod, the screw rod has a long groove part 11 arranged symmetrically in the diameter direction; the upper nut 4, the self-tightening nut 5, the lower nut 6, and the end nut 8 are hexagonal blocks, and the center hole has internal threads. Aperture and internal thread are all matched with the screw rod and external thread of bolt 1; Upper nut 4 and lower nut 6 respectively include round table holes 41,61; Round table column, and self-tightening nut 5 also comprises radially a misplaced through slit; Self-locking washer 7 has central hole, and aperture matches the screw rod of bolt and the aperture of upper nut 1, self-locking nut, lower nut 6, s...

Embodiment 2

[0033] like figure 2 , 3 , 6, 8, 9, 10, 11, the present invention provides a self-tightening bolt and nut fastening assembly, including a bolt 1 and an upper nut 4, a self-tightening nut 5, a lower nut 6, and a self-locking washer 7 that are sequentially connected and matched , end nut 8; bolt 1 is a hexagon head bolt, including a head and a screw rod, and the screw rod has a long groove portion 11 arranged symmetrically in the diameter direction; the upper nut 4, the self-tightening nut 5, the lower nut 6, and the end nut 8 are hexagonal blocks , the center hole has an internal thread, and the central aperture and internal thread are matched with the screw rod and the external thread of the bolt 1; the upper nut 4 and the lower nut 6 respectively include the round table holes 41 and 61; the self-tightening nut 5 includes the upper nut 4 and the lower nut 6 round table holes match the two round table columns, and the self-tightening nut 5 also includes a radially dislocated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com