Portable type rope winding device

A winder, portable technology, applied in the field of power transmission line maintenance equipment, can solve the problems of small circle diameter, difficult to take out, inconvenient to use, etc., to achieve the effect of being conducive to management and uniform length of inner diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

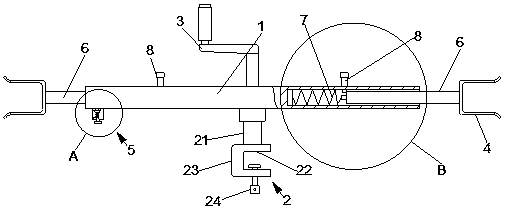

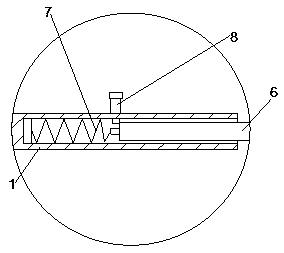

[0022] Figure 1-3 The portable rope winder shown includes a housing tube 1, which is rotatably arranged in the middle of the housing tube 1 and forms a T-shaped slot fixing mechanism 2 with the housing tube 1. The opposite hand handle 3 of the fixing mechanism 2 is symmetrically arranged at both ends of the housing tube 1, a U-shaped coil slot 4, and a clamping device for clamping the end of the rope is arranged at one end of the housing tube 1. Device 5; the U-shaped openings of the two wire slots 4 face away from each other to form a rope winding mechanism; the slot fixing mechanism 2 includes a connecting rod 21 that is rotatably connected to the middle of the casing tube 1 at one end, and is arranged on the cantilevered end of the connecting rod 21 There is a clamping seat 23 with a U-shaped opening 22 at the end and one side, and a handle bolt 24 screwed on the U-shaped opening 22 of the clamping seat 23; Structural connection; the telescopic and adjustable structure in...

Embodiment 2

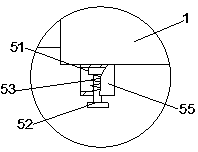

[0027] Figure 1-3 The portable rope winder shown in this example adopts a reset member and a clamping device different from that of Embodiment 1, and the rest are basically the same as Embodiment 1. Specifically, the reset part adopts a compression spring, and the compression spring is sleeved on the guide rod. The end of the guide rod is provided with a limit portion 9 at one end of the limit compression spring, and a limit portion 9 at the other end of the limit compression spring is set on the housing tube. Structure 10, the specific structure design is as follows Figure 6 As shown, the compression spring can keep the guide rod in a retracted state, while the spring pin can make the guide rod be positioned within its moving range, which can be positioned by slot positioning, non-positioning at the end or frictional resistance. The clamping device 5 includes a bracket 55 arranged at one end of the housing pipe 1, and a compression bolt 54 screwed on the bracket 55. The en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com