Chain transfer agent and preparation method and application thereof

A chain transfer agent and group technology, applied in the field of polymer material synthesis, can solve the problems of difficult regulation, poor solubility, wide molecular weight distribution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

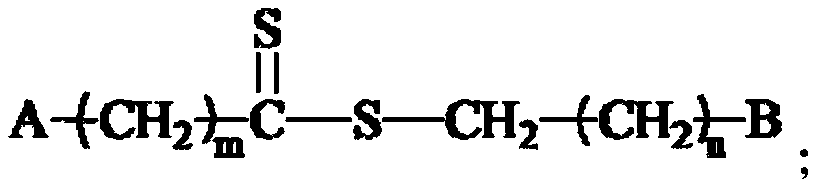

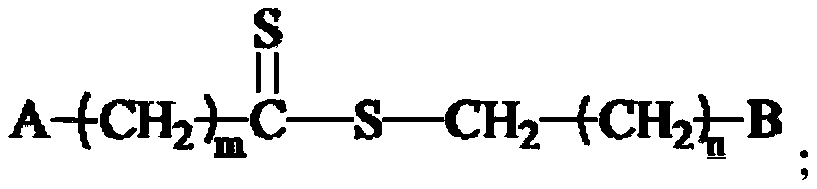

Method used

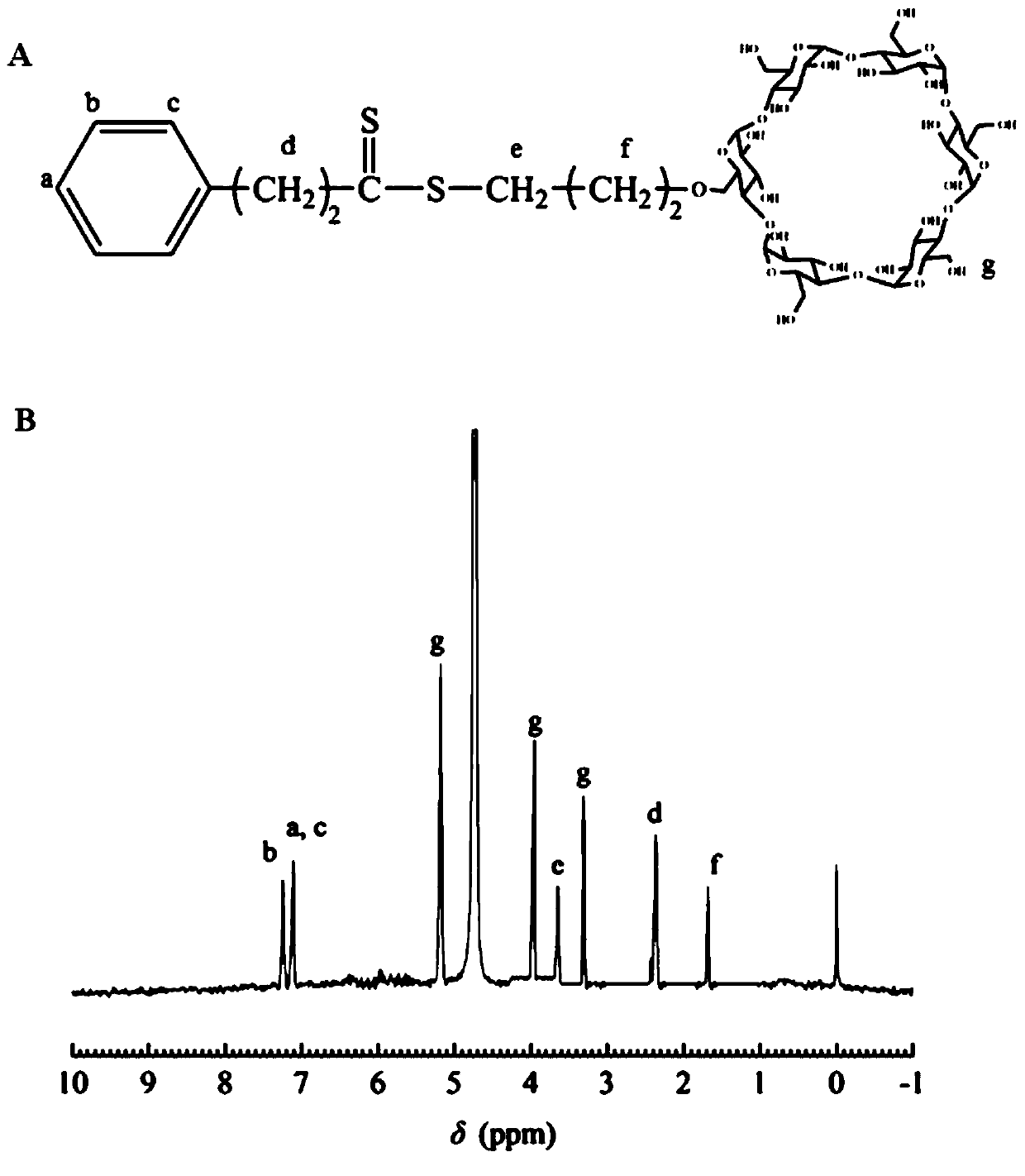

Image

Examples

Embodiment 1

[0036] Take 40mL of anhydrous THF and 0.1mol of bromoethylbenzene and mix them uniformly, then place them in a constant pressure dropping funnel to obtain a mixed solution, then take 0.105mol of magnesium strips and 0.2g of iodine in a conical flask, and drop them into the mixed solution under nitrogen protection. Solution 10mL, after the reaction, slowly add the remaining mixed solution dropwise, continue the reaction at 50°C for 2h after the dropwise addition, and add dropwise the solution containing 0.15molCS after cooling in an ice-water bath 2 35mL THF solution, after the dropwise addition, react at 50°C for 1h. Remove unreacted magnesium strips by filtration, distill off THF from the filtrate under reduced pressure, add 60 mL of ether and 40 mL of HCl with a content of 10%, take the upper organic liquid and dry it with anhydrous magnesium sulfate, and distill under reduced pressure to obtain red purple dithiocarboxylic acid, producing rate of 64%.

[0037] Finally, take...

Embodiment 2

[0039] A dithioester-type chain transfer agent grafted with α-cyclodextrin and benzene ring at the end is used to polymerize with the hydrophobic association monomer to obtain a hydrophobic association polymer containing α-cyclodextrin and benzene ring at both ends. The molecular weight is about 180,000. Dissolve 0.2 g of the polymer in 100 mL of water to prepare a polymer solution. The complete dissolution time is 1 h, and the viscosity is 205.7 mPa·s. Under the same conditions, the viscosity of conventional polyacrylamide with equal molecular weight is 80.3mPa·s. In contrast, the viscosity of the instant self-adhesive polymer system synthesized based on RAFT chain transfer agent increased by 156.2%. The viscosity recovers to 190.2mPa·s 1h after high-speed shearing, and the recovery rate can reach 92.3%.

Embodiment 3

[0041] The dithioester type chain transfer agent grafted with γ-cyclodextrin and anthracycline at the end is used to polymerize with polyacrylamide monomer to obtain polyacrylamide containing γ-cyclodextrin and anthracycline at both ends, with a molecular weight of about 130,000. 0.5 g of the polymer was dissolved in 100 mL of water to prepare a polymer solution, the complete dissolution time was 1.5 h, and the viscosity was 394.1 mPa·s. The viscosity of polyacrylamide with the same molecular weight is 189.9mPa·s, compared with that, the viscosity of the instant self-adhesive polymer system synthesized based on RAFT chain transfer agent is increased by 107.5%. The viscosity recovers to 369.7mPa·s after high-speed shearing for 1 hour, and the recovery rate can reach 93.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com