A stainless steel material, a heating tube using the material and its application

A technology of stainless steel and heating tubes, applied in the field of stainless steel materials, can solve the problems of declining yield of heating tubes, difficulties in refining and processing, and increased production costs, etc., and achieve the effects of reducing the rate of broken tubes, making the smelting process easier, and reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

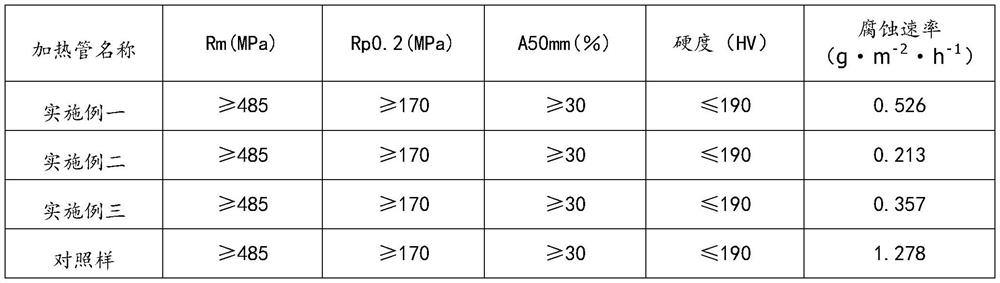

Examples

preparation example Construction

[0023] A kind of preparation method of stainless steel material of the present invention, comprises the following steps:

[0024] Take carbon steel, metal nickel, metal chromium, metal molybdenum, metal aluminum and metal titanium, and smelt them in an electric furnace to obtain molten steel;

[0025] Under vacuum or an inert atmosphere, the molten steel is subjected to secondary refining to obtain a billet, and the composition of the billet is adjusted to reach the content of each element in the stainless steel material described in any one of the above;

[0026] Continuous casting or die casting of billets to produce rough steel plates with a width of 1200-1300 mm and a thickness of 200-240 mm;

[0027] The thick steel plate is hot-rolled into steel coil twice, and the thickness of the steel coil is 3-5mm;

[0028] The steel coil is cut, twice cold rolled and heat treated to make a steel plate with a thickness of 0.25-1mm and a width of less than 400mm, that is, stainless s...

Embodiment 1

[0037] A kind of preparation method of stainless steel material of the present invention, comprises the following steps:

[0038] 1) Take carbon steel, metal nickel, metal chromium, metal molybdenum, metal aluminum and metal titanium, and smelt them in an electric furnace to obtain molten steel;

[0039] 2) Under vacuum atmosphere, carry out secondary refining to above-mentioned molten steel, obtain billet, adjust the composition of billet to be:

[0040] C 0.03%, Si 1.00%, Mn 1.00%, Ni 16.00%, Cr 18.00%, Mo 0.50%, Al 0.15%, Ti 0.10%, Cu 0.75%, P 0.030%, S 0.015%, Fe balance;

[0041] 3) continuous casting billets, made of rough steel plates with a width of 1200 mm and a thickness of 200 mm;

[0042] 4) The thick steel plate is hot-rolled into steel coil twice, and the thickness of the steel coil is 3mm;

[0043] 4) The steel coil is cut, cold rolled twice and heat treated to make a steel plate with a thickness of 0.25mm and a width of 400mm, that is, a stainless steel mater...

Embodiment 2

[0045] A kind of preparation method of stainless steel material of the present invention, comprises the following steps:

[0046] 1) Take carbon steel, metal nickel, metal chromium, metal molybdenum, metal aluminum and metal titanium, and smelt them in an electric furnace to obtain molten steel;

[0047] 2) Under a nitrogen atmosphere, the above-mentioned molten steel is subjected to secondary refining to obtain a billet, and the composition of the billet is adjusted to be:

[0048] C 0.005%, Si 0.30%, Mn 0.50%, Ni 20.00%, Cr 23.00%, Mo 3.00%, Al0.65%, Ti 0.65%, Cu 0.50%, P 0.02%, S 0.010%, Fe balance;

[0049] 3) Die-cast steel billets to make rough steel plates with a width of 1300 mm and a thickness of 240 mm;

[0050] 4) The rough steel plate is hot-rolled into steel coil twice, the thickness of the steel coil is 5mm, the starting temperature of hot rolling is 1050°C, the final rolling temperature is 950°C, and the maintenance rolling temperature is 1100°C;

[0051] 4) S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com