Method of pressure relief of dead oil section of liquid pipeline

A liquid pipeline and pressure relief technology, applied in functional valve types, instruments, safety valves, etc., can solve problems such as environmental pollution, seepage, and safety accidents, and achieve the effects of improving property safety, high accuracy, and timely alarm speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

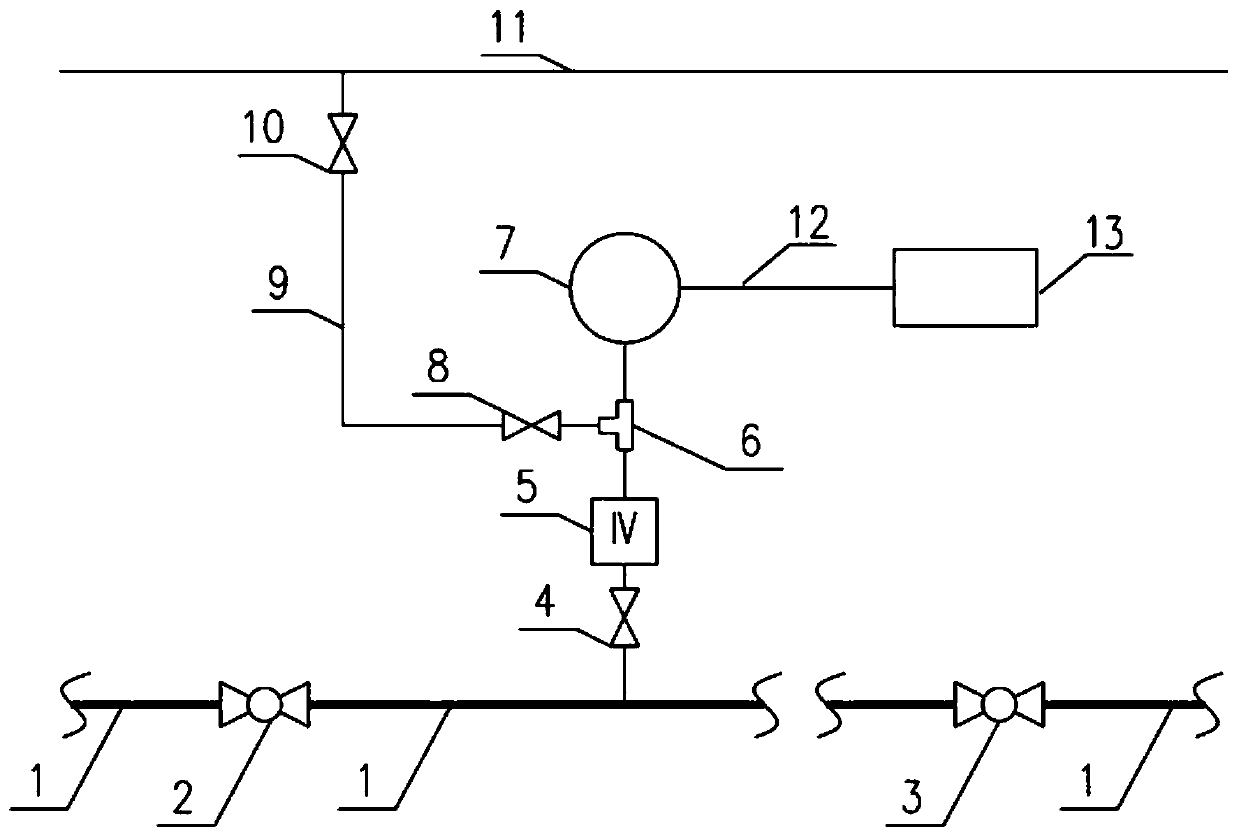

[0024] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

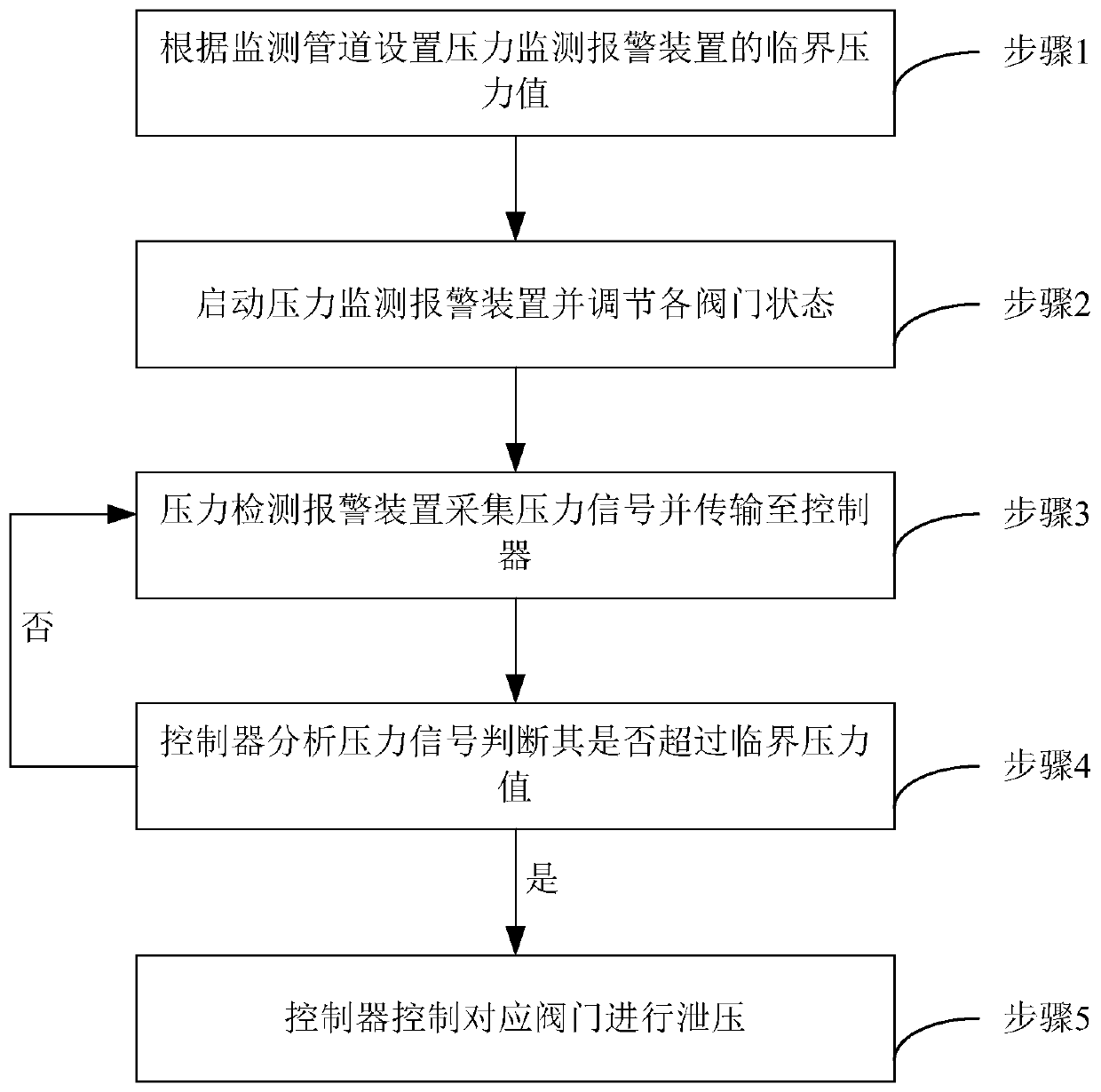

[0025] Such as figure 1 As shown, what is described in the embodiment of the present invention is a method for releasing pressure in a dead oil section of a liquid pipeline, the method comprising:

[0026] Step 1, setting the critical pressure value of the pressure monitoring alarm device 7 and the controller 13;

[0027] Step 2, turn on the pressure monitoring and alarm device 7 and the controller 13, and make the first valve 2, the second valve 3, the third valve 8 and the fourth valve 10 all in the disconnected state;

[0028] Step 3, the pressure monitoring and alarming device 7 collects the pressure signal in real time, and transmits the collected pressure signal to the controller 13;

[0029] Step 4, the controller 13 analyzes the received pressure signal, and when the pressure value is greater than the critical pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com