A kind of assembly process and assembly tooling of the contact pressure spring of the arc extinguishing chamber

A contact pressure spring and assembly tooling technology, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problem that the pin hole of the tie rod joint and the threaded hole of the static end of the arc extinguishing chamber cannot be guaranteed to be in the circumferential direction of the arc extinguishing chamber. The positional relationship meets the design and assembly requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

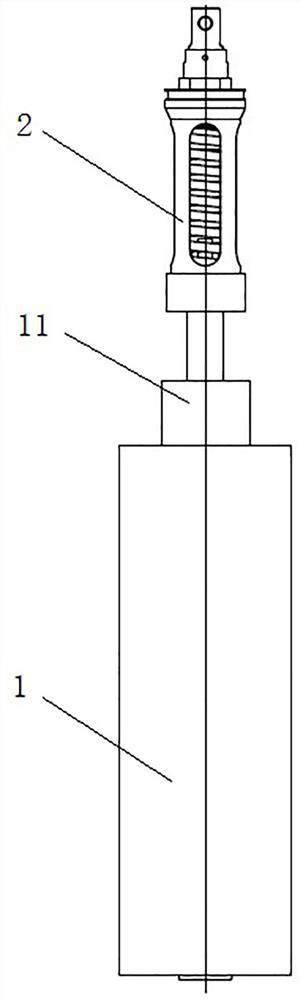

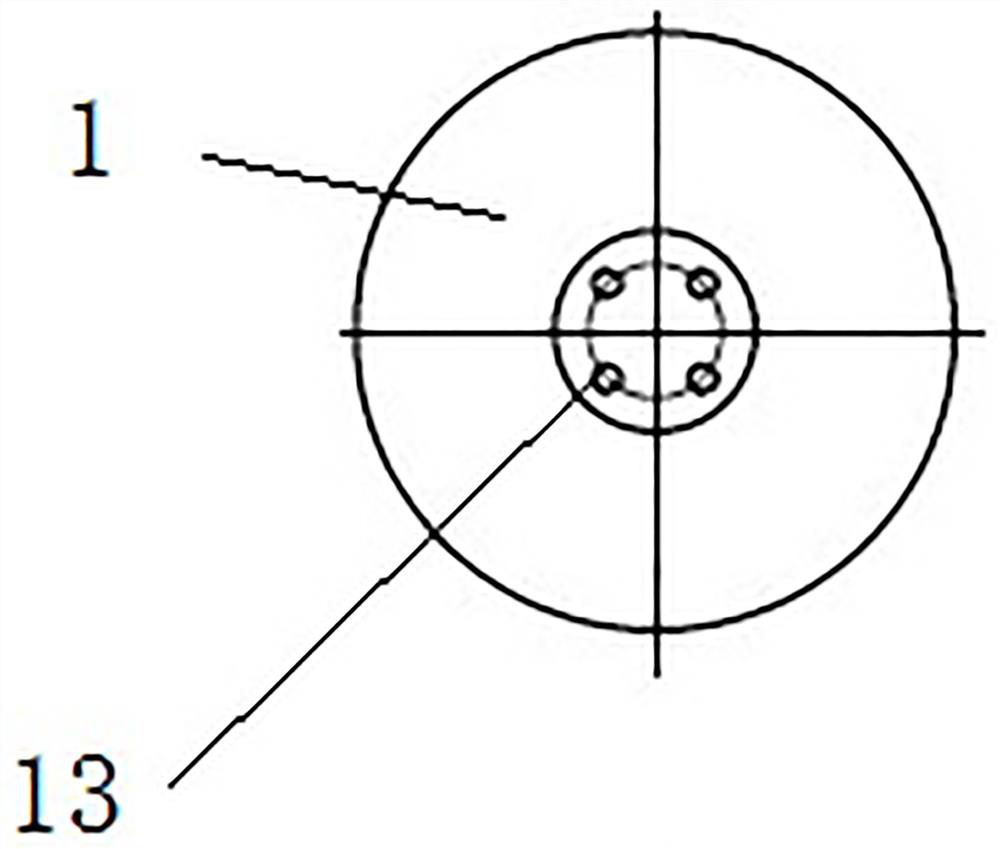

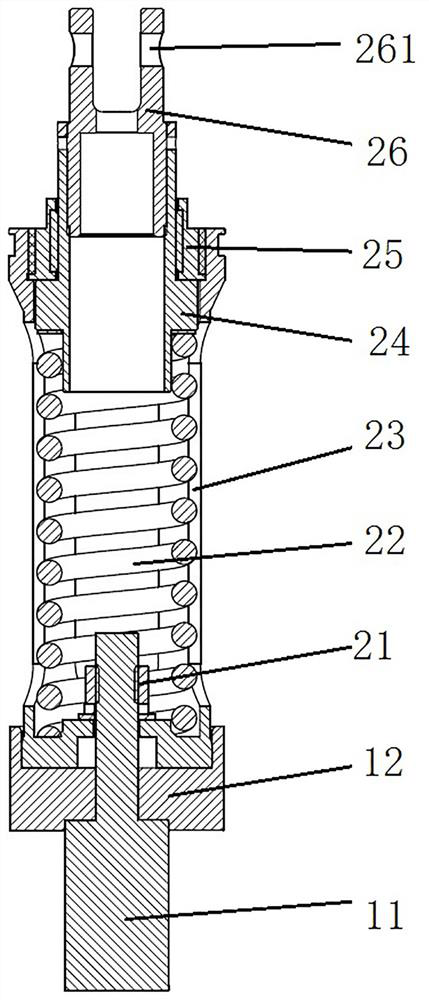

[0034] In the present invention, the arc extinguishing chamber and the contact pressure spring assembly suitable for the assembly tooling of the contact pressure spring are as follows: figure 1 As shown, the contact compression spring assembly 2 is installed on the moving contact rod 11 connected by the moving contact transmission at the upper end of the arc extinguishing chamber 1 . Among them, such as figure 2 As shown, the lower end of the arc extinguishing chamber 1 is provided with four static end threaded holes 13 . And the concrete composition and structure of contact clip spring assembly 2 are as follows: image 3 As shown, the contact compression spring assembly 2 includes a spring barrel 23, a contact compression spring 22 sleeved in the spring barrel 23, a slider 24, a joint body 26 and a fixed stopper fixedly assembled with the spring barrel 23, wherein the slider The block 24 and the joint body 26 are threaded and fixedly assembled together to form a pull rod j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com