Wide-section dummy bar and guiding device thereof

A dummy bar and section technology, applied in the field of guide devices, can solve the problems of twisted forward movement, left and right deviation of the dummy bar, inability to ensure that the dummy bar shaft 101 does not deviate, etc., so as to increase the accuracy and ensure the accuracy guided effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

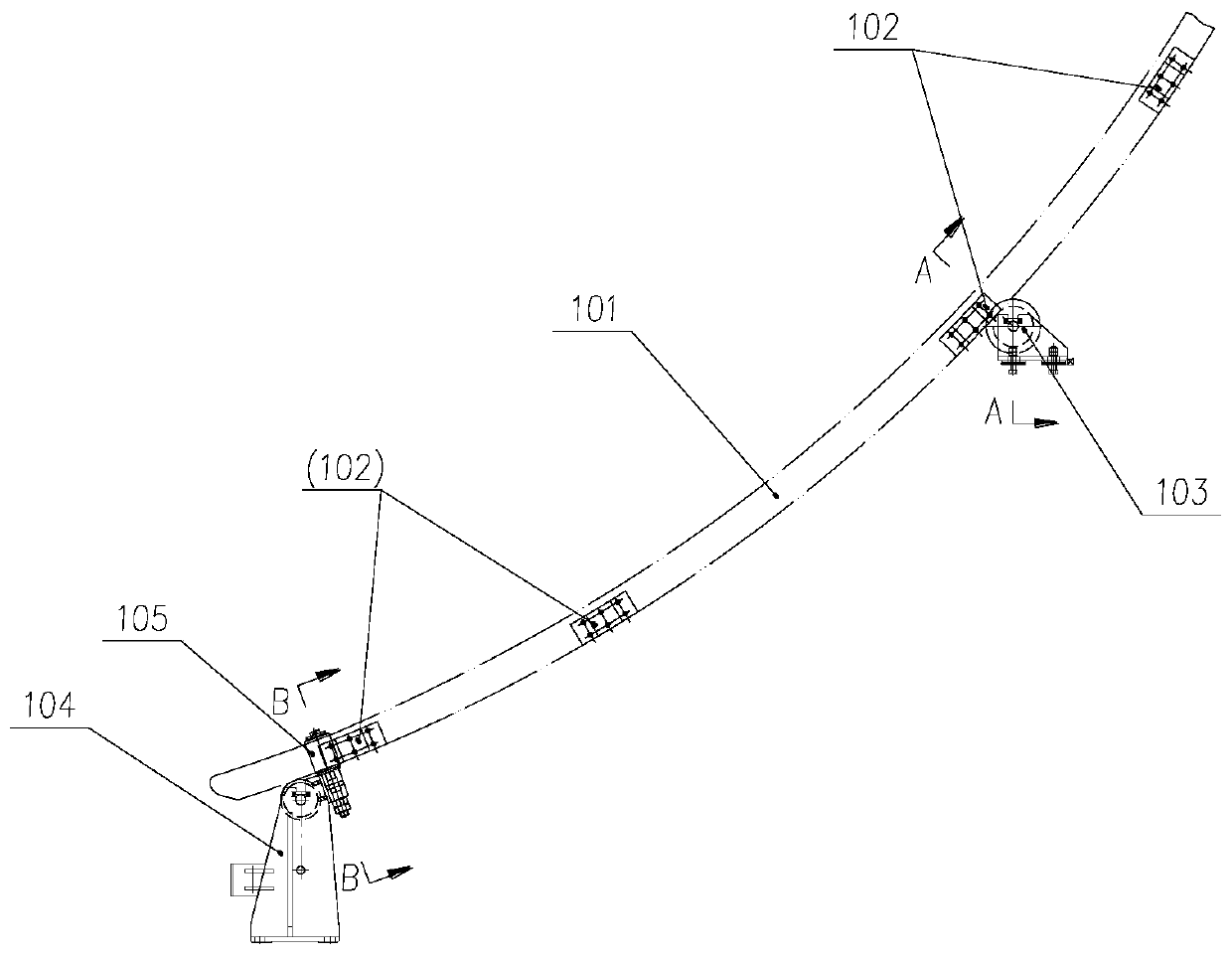

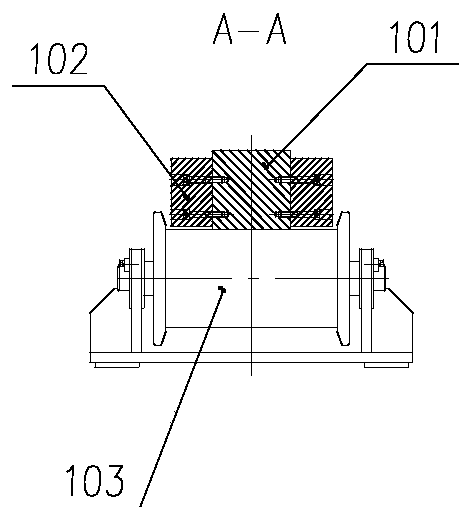

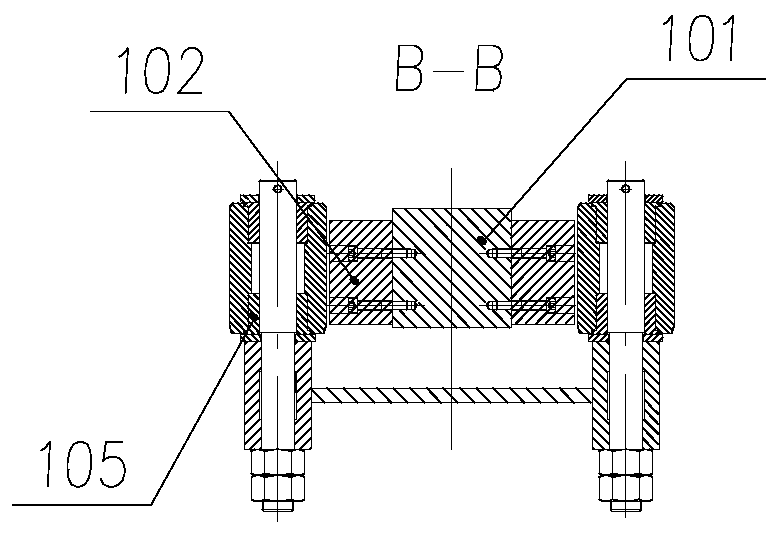

[0034] Such as Figure 12 to Figure 15 As shown, a wide-section dummy bar of the present invention includes a dummy bar body 101 and a side guide plate 102, side guide plates 102 are respectively arranged on both sides of the dummy bar body 101, and the wide-section dummy bar body 101 part The width and height of the part usually range from 120mm to 180mm, the sum of the width of the side guide plates 102 on both sides and the dummy bar shaft 101 ranges from 250mm to 400mm, and the height of the side guide plates 102 is from 40mm to 60mm, so that it can ensure The weight of the dummy bar does not increase too much, while ensuring lateral guidance of the strand.

[0035] The side guide mode of the dummy bar and the dummy bar storage device of the present invention is as follows: Figure 7 ~ Figure 15 shown.

[0036] Such as Figure 7 As sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com