Turbine for an exhaust turbocharger having a dual branch turbine housing and valve arrangement for branch connection and waste gate control

A technology of turbine housing and exhaust gas turbine, which is applied to valve devices, machines/engines, lift valves, etc., can solve the problem that the shape of the valve body 36 cannot be freely selected, and achieve thermal deformation compensation and reduce space requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

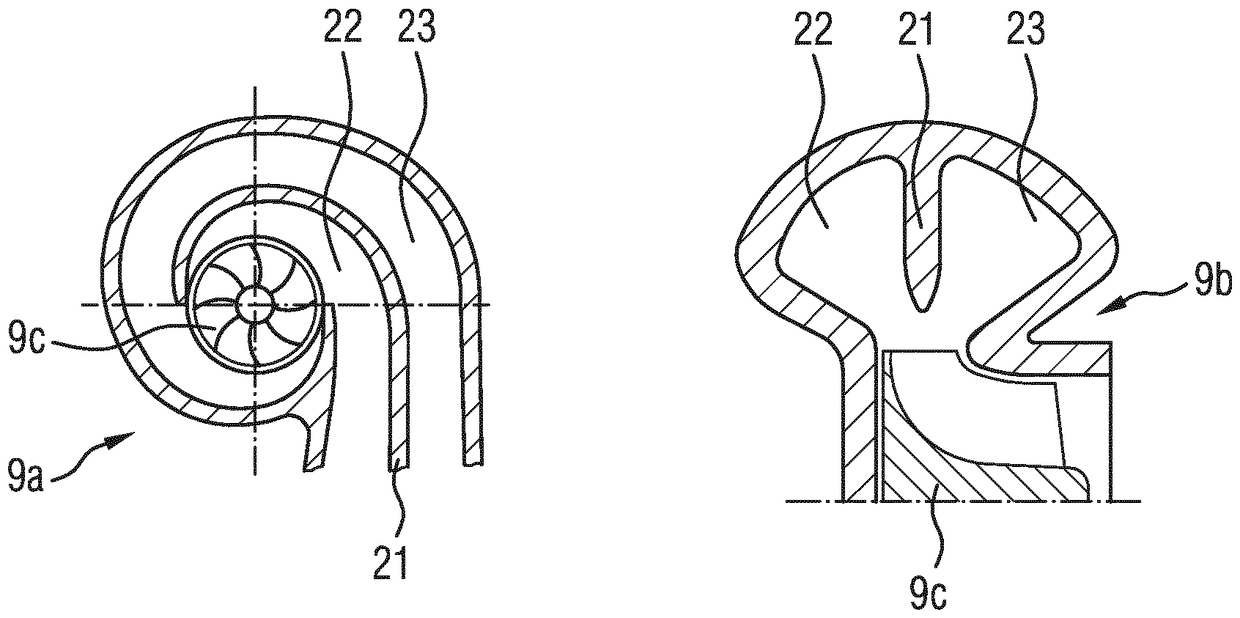

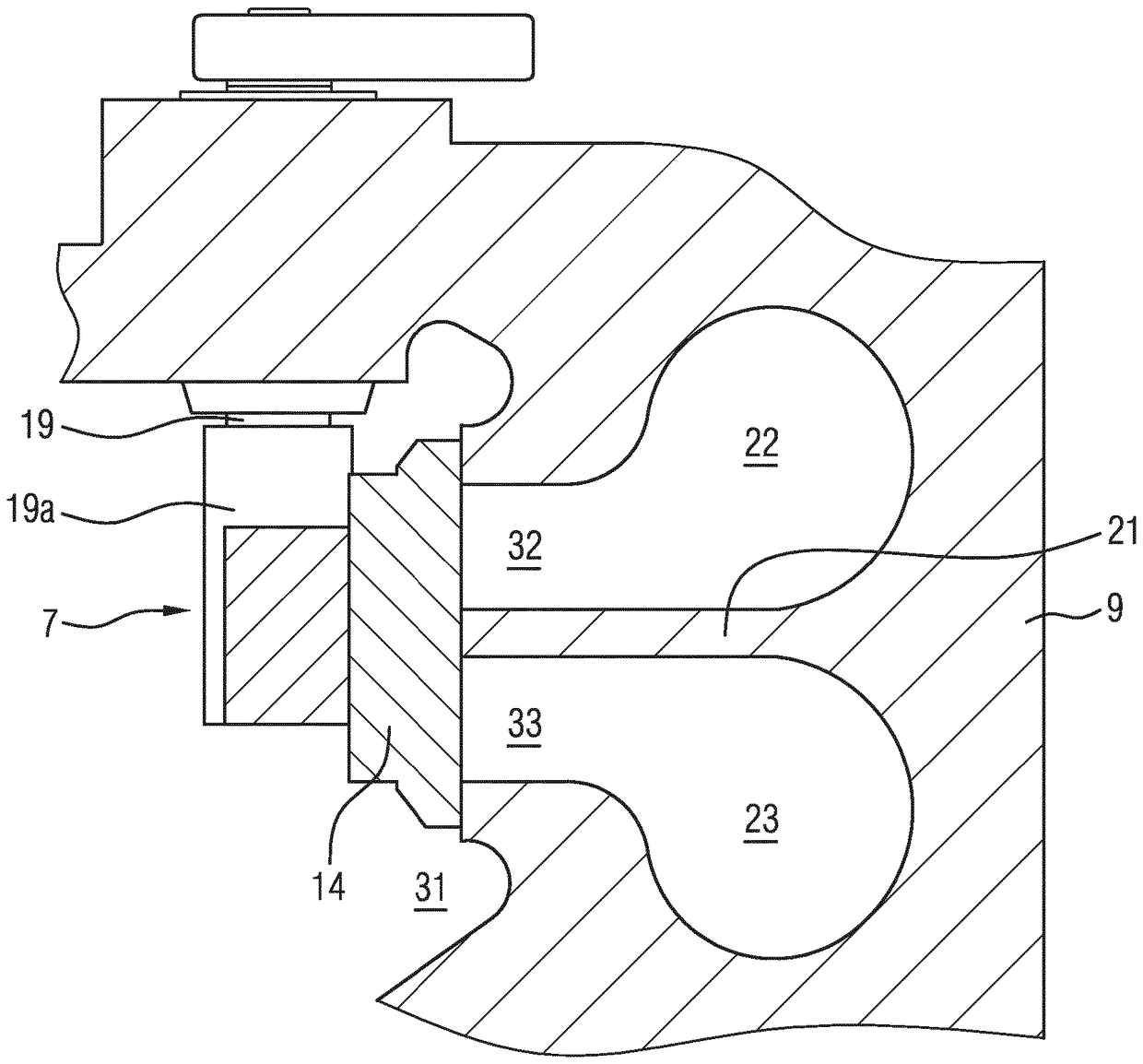

[0030] To explain the first exemplary embodiment, Figure 9 Details of the turbine housing are shown in cross-section.

[0031] In this first exemplary embodiment, two exhaust gas volutes 22 , 23 are arranged in the turbine housing 9 , through which exhaust gas can flow. The partition wall 21 is located between the two exhaust gas volutes 22 , 23 . Furthermore, the turbine housing 9 has an outlet opening 31 through which a part of the exhaust gas mass flow escapes when the wastegate opening is open. Furthermore, in the exemplary embodiment shown, a linear valve with a valve element 35 is provided.

[0032] In order to close the wastegate opening 13, the valve element 35 is guided from the outlet chamber 31 in the direction of the valve seat 13a, and in order to open the wastegate opening 13, the valve element 35 can be lifted from the valve seat 13 via the displacement shaft 30 in the longitudinal direction of the shaft The axial direction of the axis 30 a enters the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com