Turbine for an exhaust turbocharger having a two-volute turbine housing and a linear valve for volute connection and wastegate control

A technology for turbine casings and exhaust gas turbines, which is applied in the direction of machines/engines, lift valves, valve devices, etc., can solve problems such as large structures, and achieve the effect of reducing space requirements and saving space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

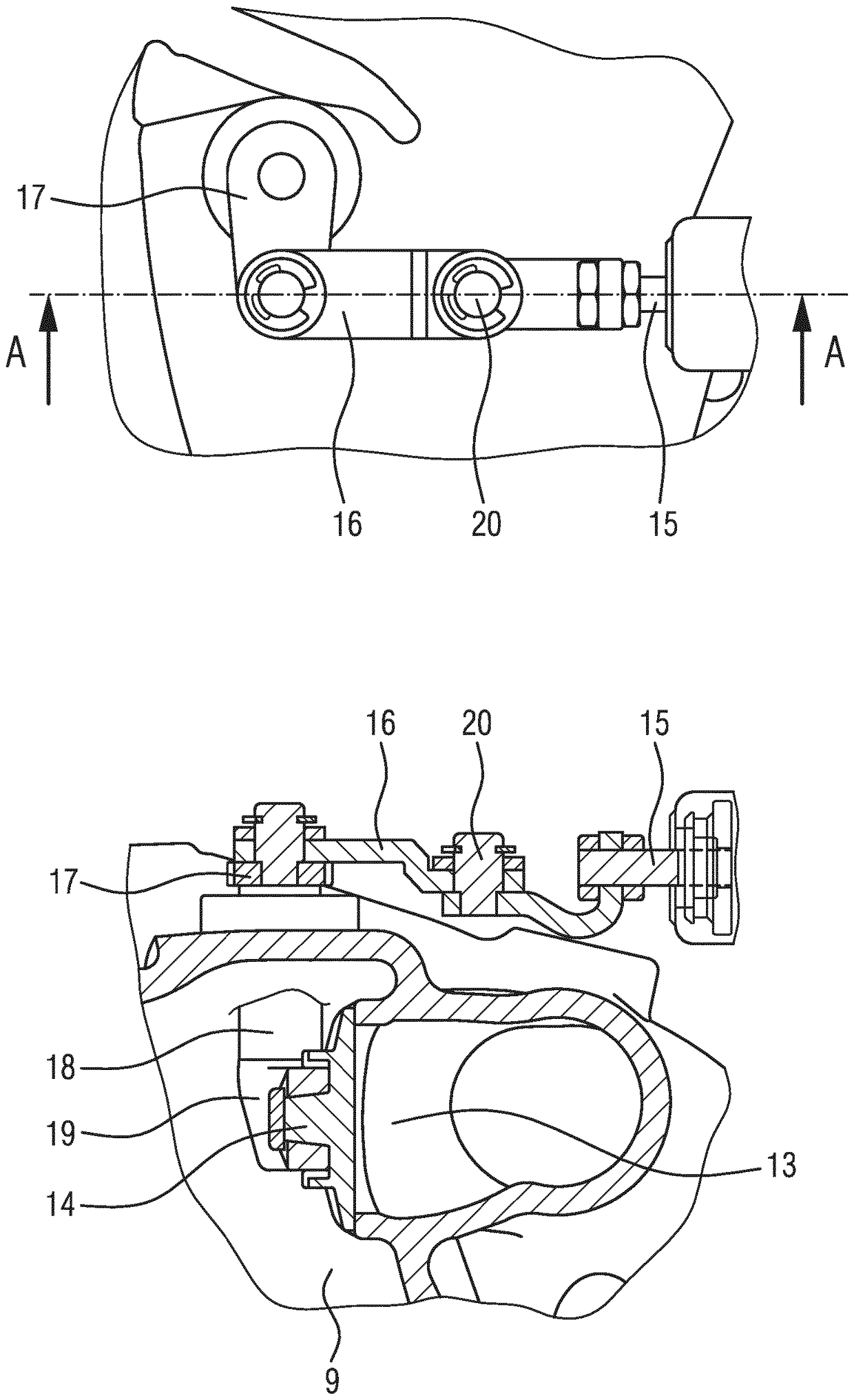

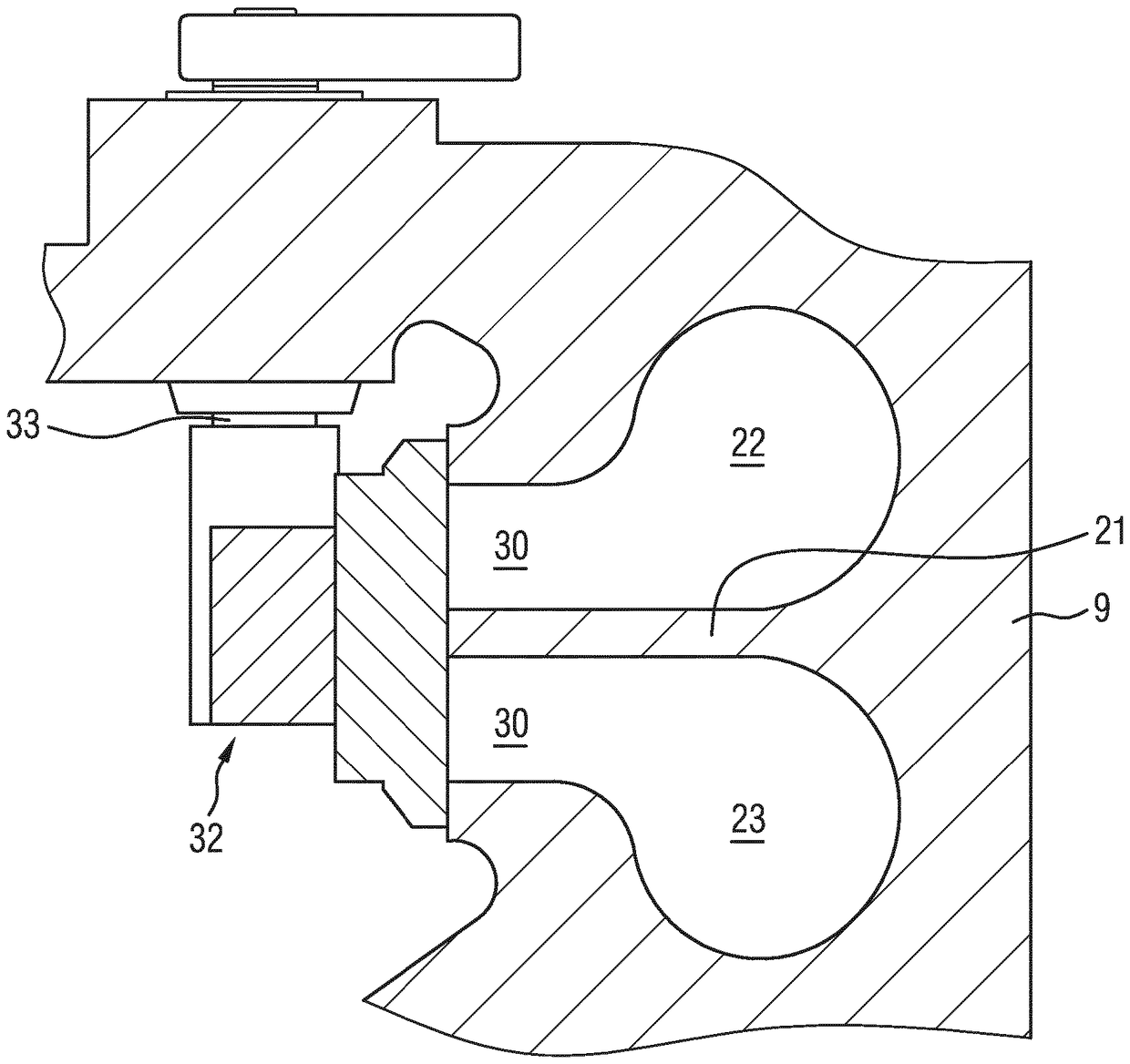

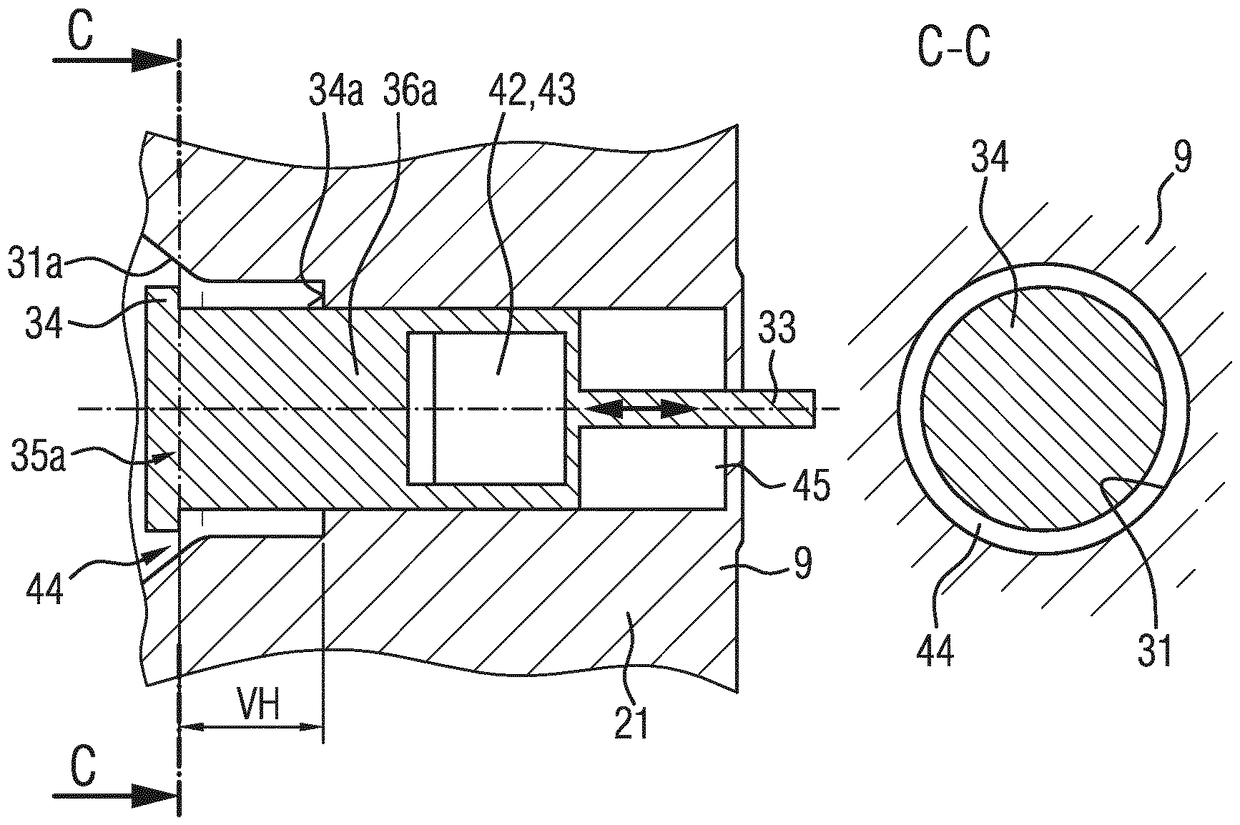

[0041] The invention provides a turbine for an exhaust gas turbocharger, the turbine having a turbine housing comprising two volutes through which exhaust gas can flow and between which Partition walls are provided between the shells. Furthermore, a wastegate valve designed as a linear valve with a linear valve element is provided. The linear valve element is connected to a displacement shaft 33 for actuating the linear valve element 35a, the displacement shaft 33 having a shaft longitudinal axis 33a. The displacement shaft 33 is guided through the partition wall 21 to the outside of the turbine housing 9 in the direction of the partition wall plane spanned by the partition wall and is arranged to be movable in the partition wall 21 in the axial direction of its shaft longitudinal axis 33a. Move to guide. In order to close the wastegate outlet 30, the linear valve element 35a is guided from the direction of the outlet chamber 31, ie from the outside of the volute 22, 23, tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com