Elastic pin press-fitting base

An elastic pin, press-fit technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of pin hole deformation, pin jamming, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

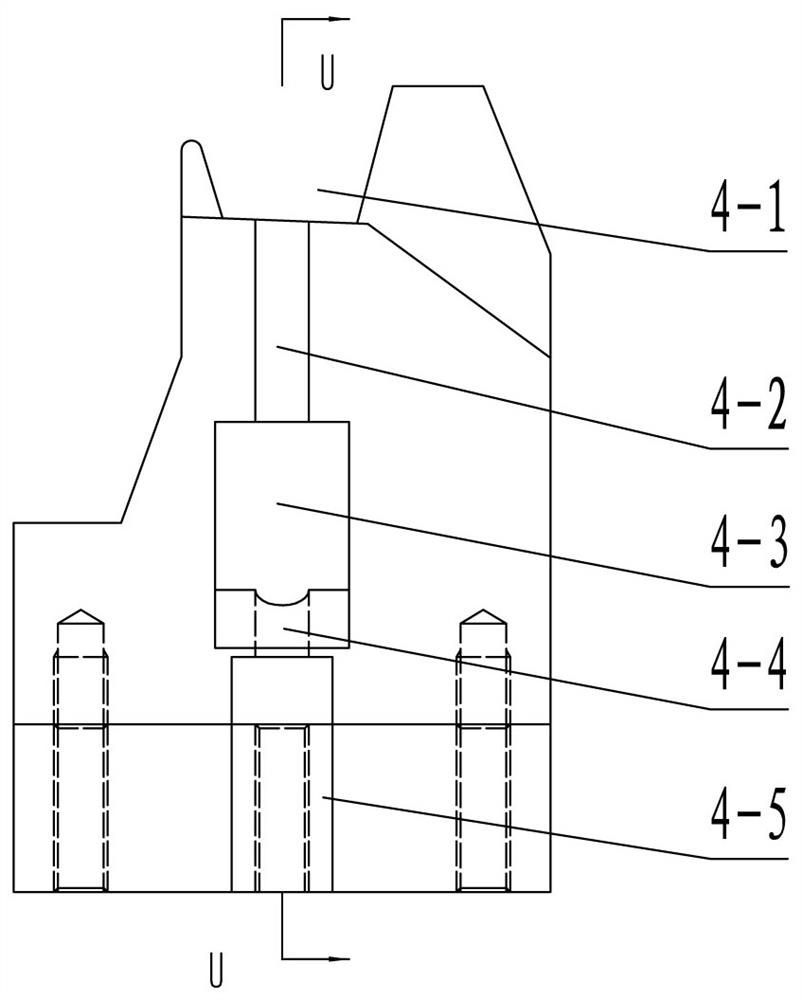

[0030] In the transmission assembly, the elastic pins and the elastic pin holes of the connecting parts have a large interference fit, and iron filings will be generated during the press-fitting process. The present invention solves the jamming deformation problem by providing a chip removal structure on the press-fitting base. The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

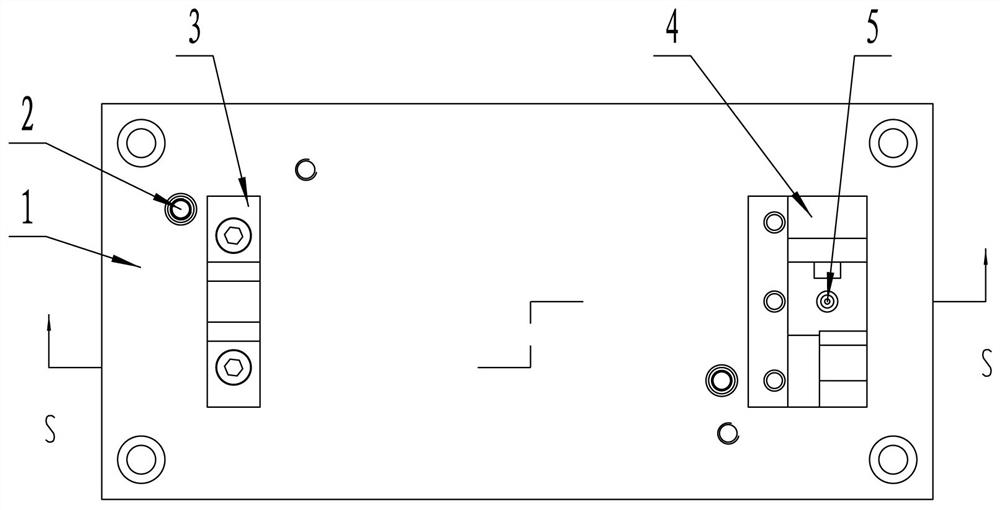

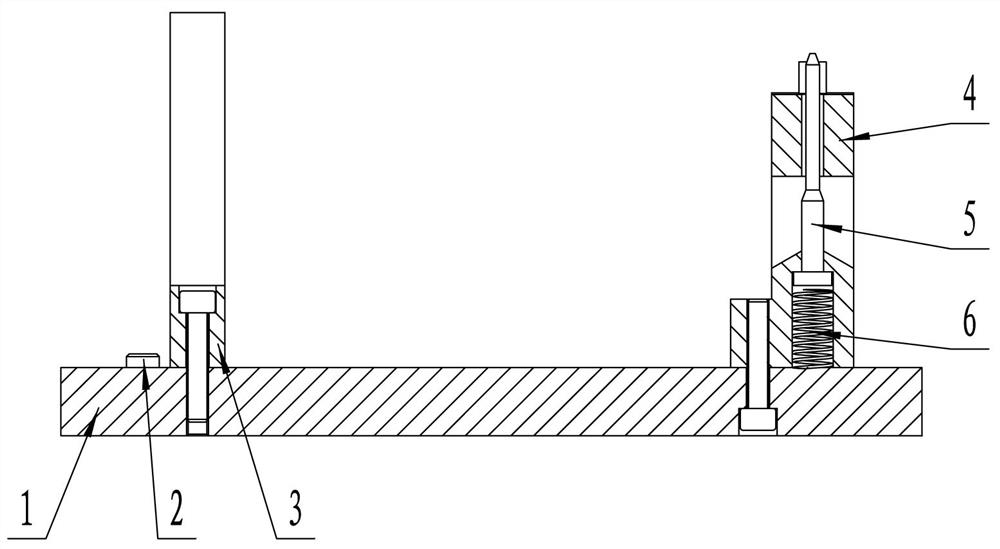

[0031] figure 1 with figure 2 The elastic pin pressing base shown mainly includes a bottom plate 1, a positioning block 4, a guide pin 5 and a spring 6. The positioning block 4 is fixed and installed on the bottom plate 1 by a plurality of bolts. Positioning pin 2 for inserting and positioning; in order to improve the stability of press-fitting, a support block 3 opposite to the positioning block 4 is also fixedly connected to the base plate 1 through bolts, and the support block 3 is provided with a matching pin for the press-fitting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Verticality | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com