Road construction machines of the paver or feeder type

A paving machine and feeding machine technology, applied in roads, roads, road repairs, etc., can solve problems such as blockage of paving materials, increased gap between the side wall of the flap and the side wall of the hopper, and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

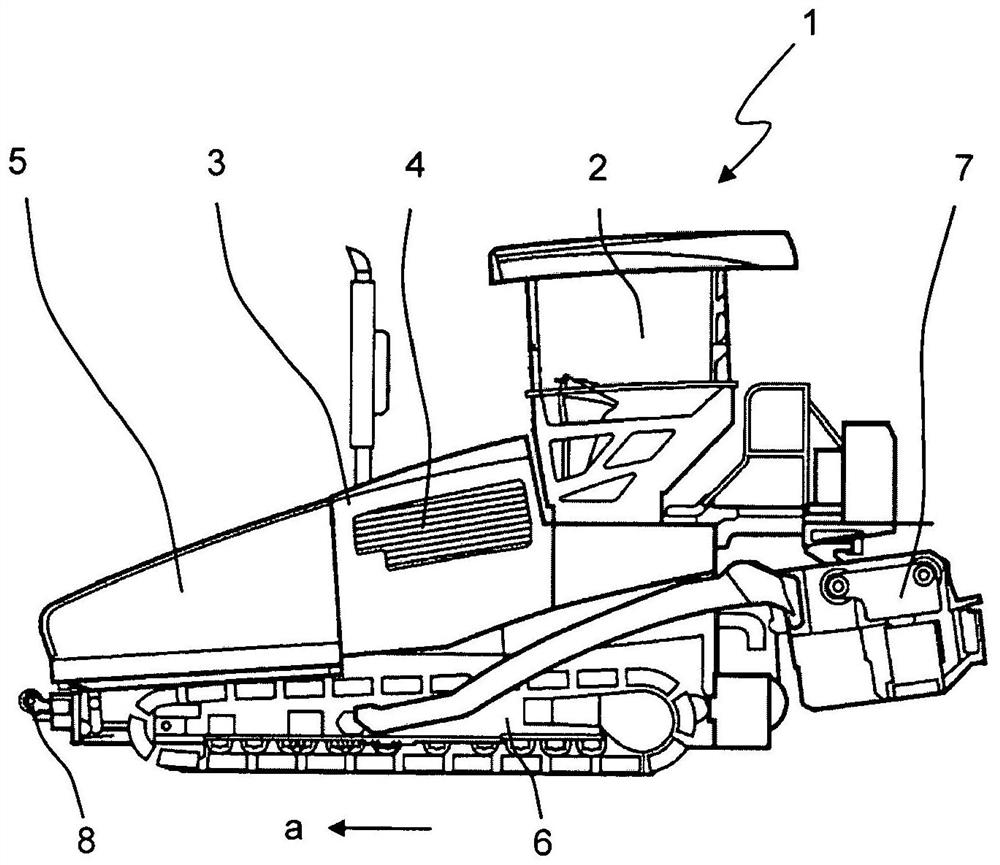

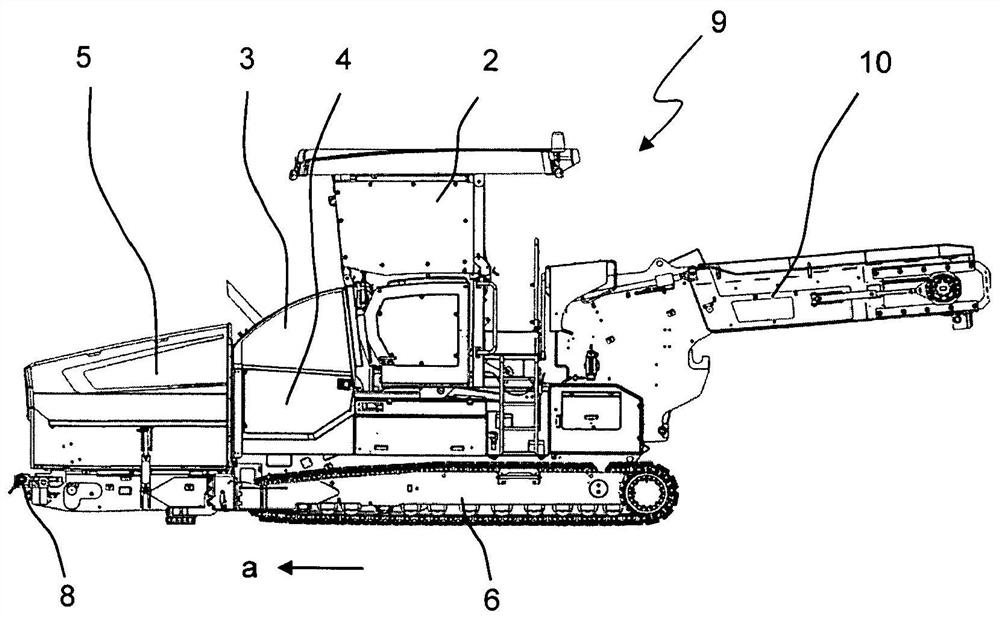

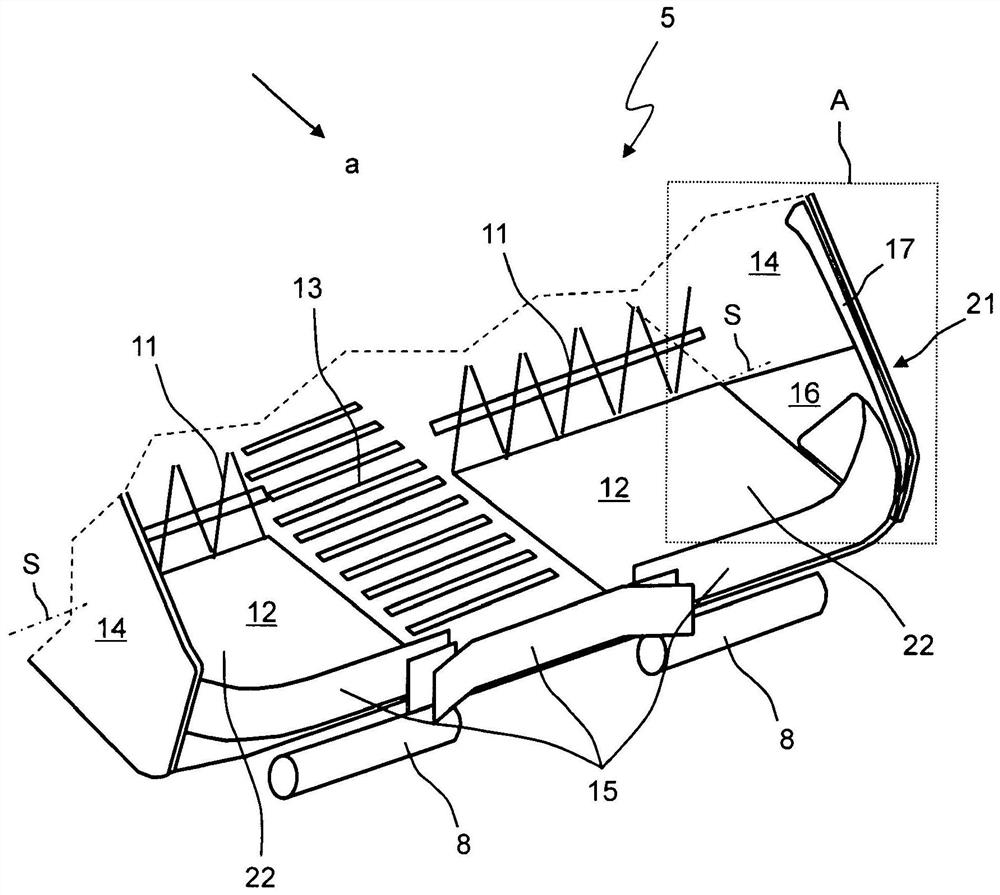

[0026] figure 1 and figure 2 A typical road construction machine is shown, namely a paving machine 1 ( figure 1 ) and feeder 9 ( figure 2 ). The road construction machine 1 , 9 comprises an operator station 2 and a frame 3 . Furthermore, they comprise a chassis 6 driven by a drive unit 4 , which in most cases comprises a diesel internal combustion engine, by means of which the road construction machines 1 , 9 can be moved forward in a working direction a when in working mode. At its rear, the road paver 1 is provided with a screed 7 by means of which the paving material can be distributed, smoothed and compacted transversely to the working direction a. In contrast, the feeder 9 does not include the screed 7 , but is provided with a feed conveyor 10 via which the paving material can be fed into the paving machine 1 . Both the paving machine 1 and the feeder 9 have a hopper 5 for holding paving materials. The feeder 9 can convey, ie load, the paving material in its hoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com