Feeding device of heating furnace

A feeding device and heating furnace technology, which is applied to lighting and heating equipment, furnaces, furnace components, etc., can solve the problems of high labor intensity of workers, long time for billets to be released from the furnace, and reduce manual operation time and labor intensity. The effect of speeding up the feeding speed and improving production efficiency

Inactive Publication Date: 2019-10-11

湖北长怡特殊材料科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the heated billet comes out of the furnace, it is also clamped by the worker with a jig. The disadvantages of the existing method are: long time and low efficiency: only one billet can be clamped at a time. After clamping, it is necessary to push the billet into the furnace with a bar location, waste of time, and low efficiency; the billet takes a long time to come out of the furnace, and the safety of the workers is low: the heated billet can only be clamped by the worker with a clamp, and the temperature is higher than 1000 ° C, which is prone to danger; the labor intensity of the workers is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

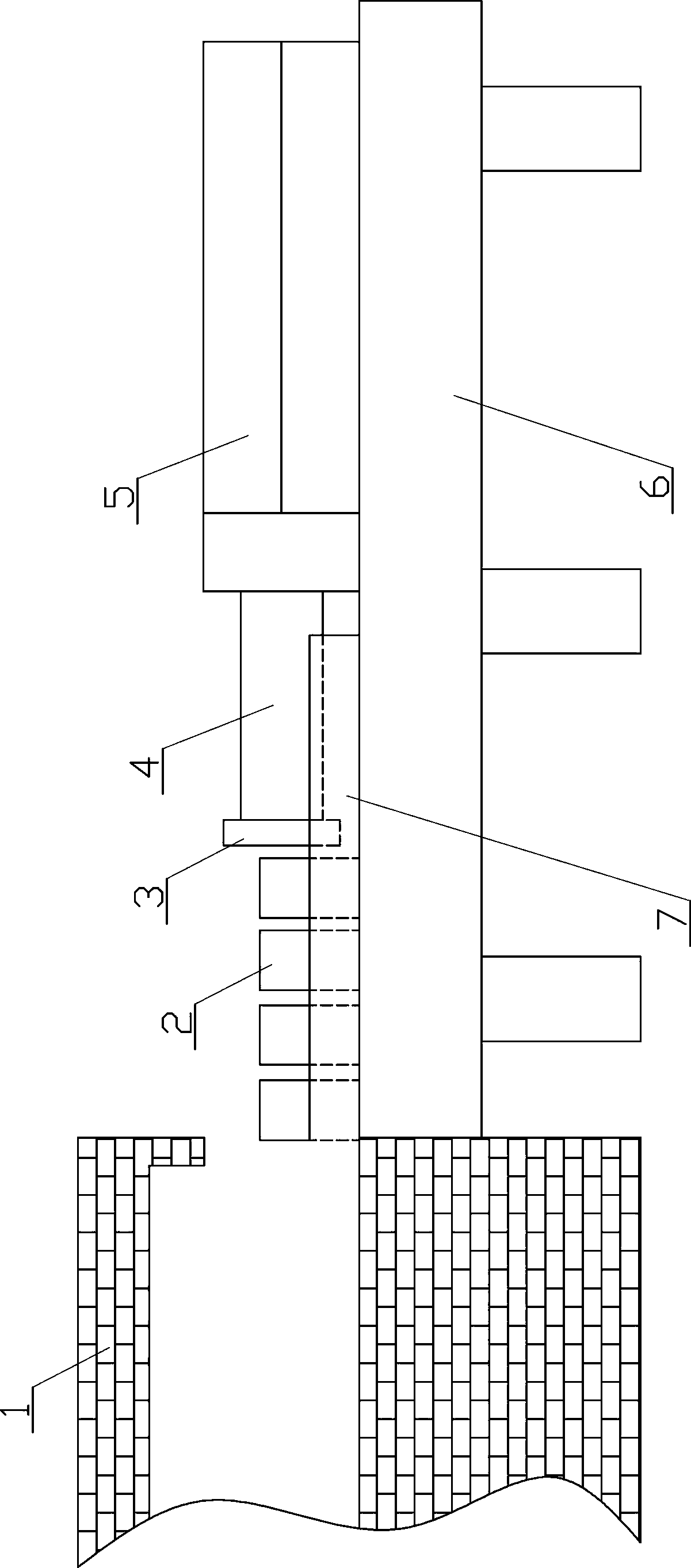

[0009] see figure 1 , the present embodiment includes a base 6 fixed on one side of the feed port of the heating furnace 1, the upper front end of the base 6 is used to place the material 2 to be heated, the upper rear end of the base 6 is fixedly equipped with an oil cylinder 5, and the front end of the piston rod 4 of the oil cylinder 5 A push plate 3 is housed.

[0010] The front end of the upper surface of the base 6 in this embodiment is equipped with a material slideway 7 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention relates to the field of heating furnace auxiliary equipment, in particular to a feeding device of a heating furnace. The feeding device comprises a base fixed to one side of a feeding hole of the heating furnace; the upper front end of the base is used for holding a material to be heated; the upper rear end of the base is fixedly provided with an oil cylinder; and a piston rod of theoil cylinder is provided with a push plate. The feeding device of the heating furnace greatly shortens the manual operating time and reduces the labor strength, and greatly lowers the potential safety hazard.

Description

technical field [0001] The invention relates to the field of heating furnace auxiliary equipment, in particular to a heating furnace feeding device. Background technique [0002] The existing billet heating is to manually clamp the billet into the furnace, and only one billet can be clamped at a time, and then the billet is pushed to the designated position with a special bar for pushing the billet. When the heated blank comes out of the furnace, it is also clamped by the worker with a clamp. The disadvantages of the existing method are: long time and low efficiency: only one blank can be clamped at a time. After clamping, it is necessary to use a bar to push the blank into the furnace to specify The location wastes time and the efficiency is very low; the billet takes a long time to come out of the furnace, and the safety of the workers is low: the heated billet can only be clamped by the worker with a clamp, and the temperature is higher than 1000 ° C, which is prone to da...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): F27D3/00

CPCF27D3/0084F27D2003/0001

Inventor 陈俊波刘鹏涛卢敏

Owner 湖北长怡特殊材料科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap