Method and apparatus for winding band-shaped rubber member

A winding device and rubber technology, which is applied to tires, household appliances, and other household appliances, can solve the problems of different cross-sectional shapes and deformation, and achieve the effect of suppressing the amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

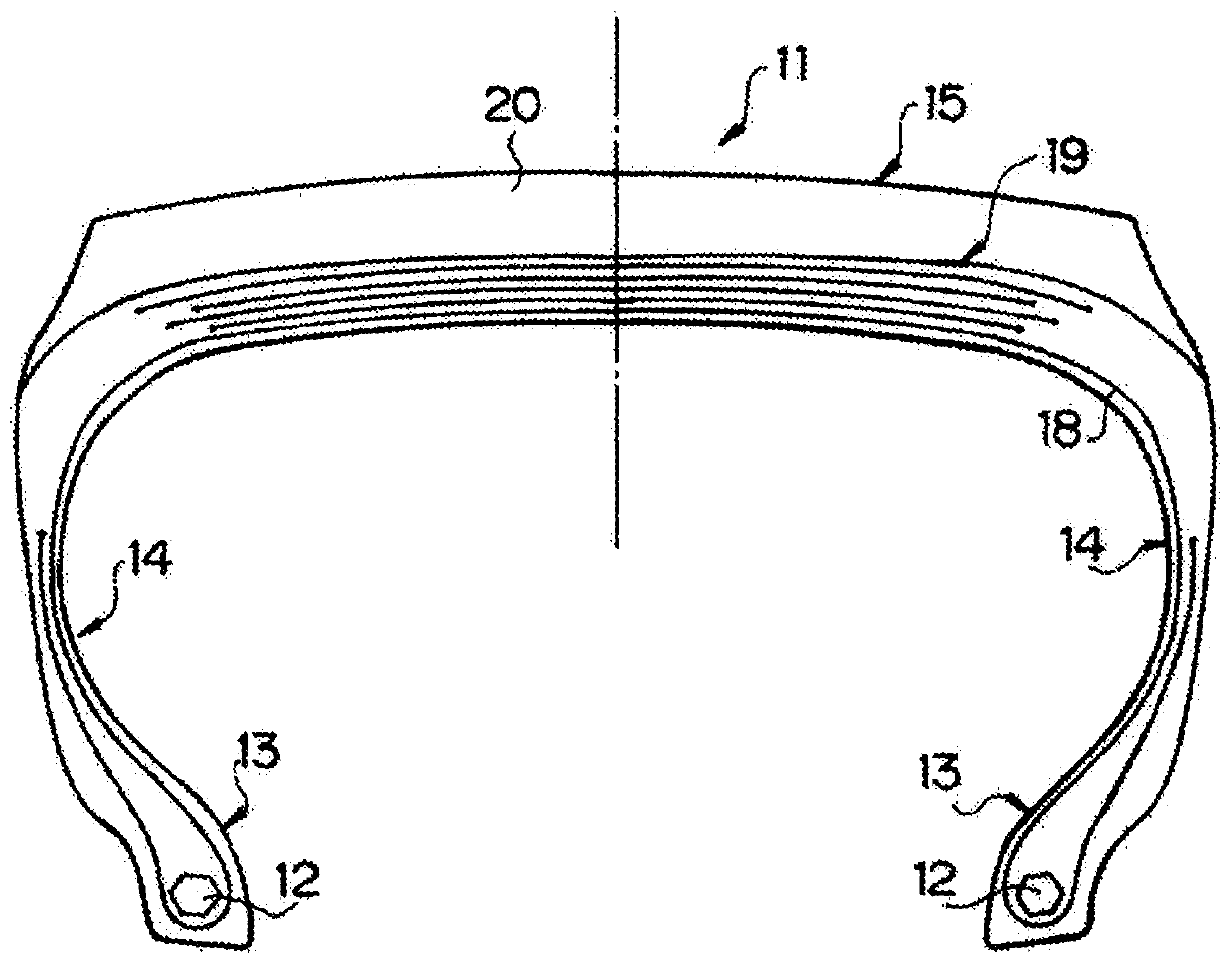

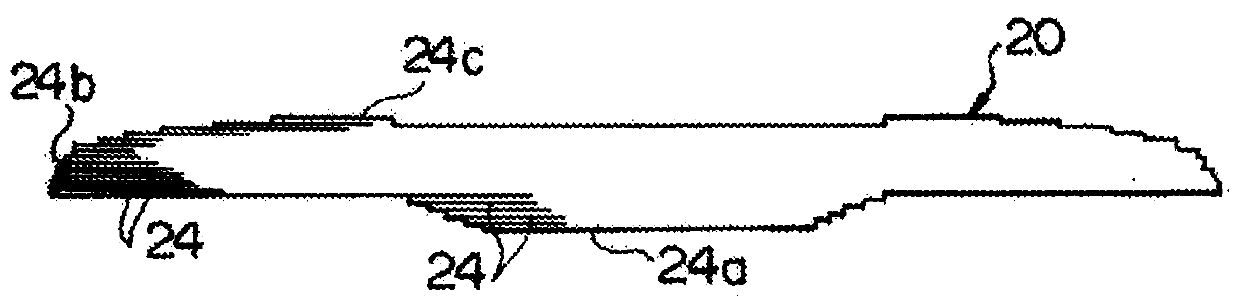

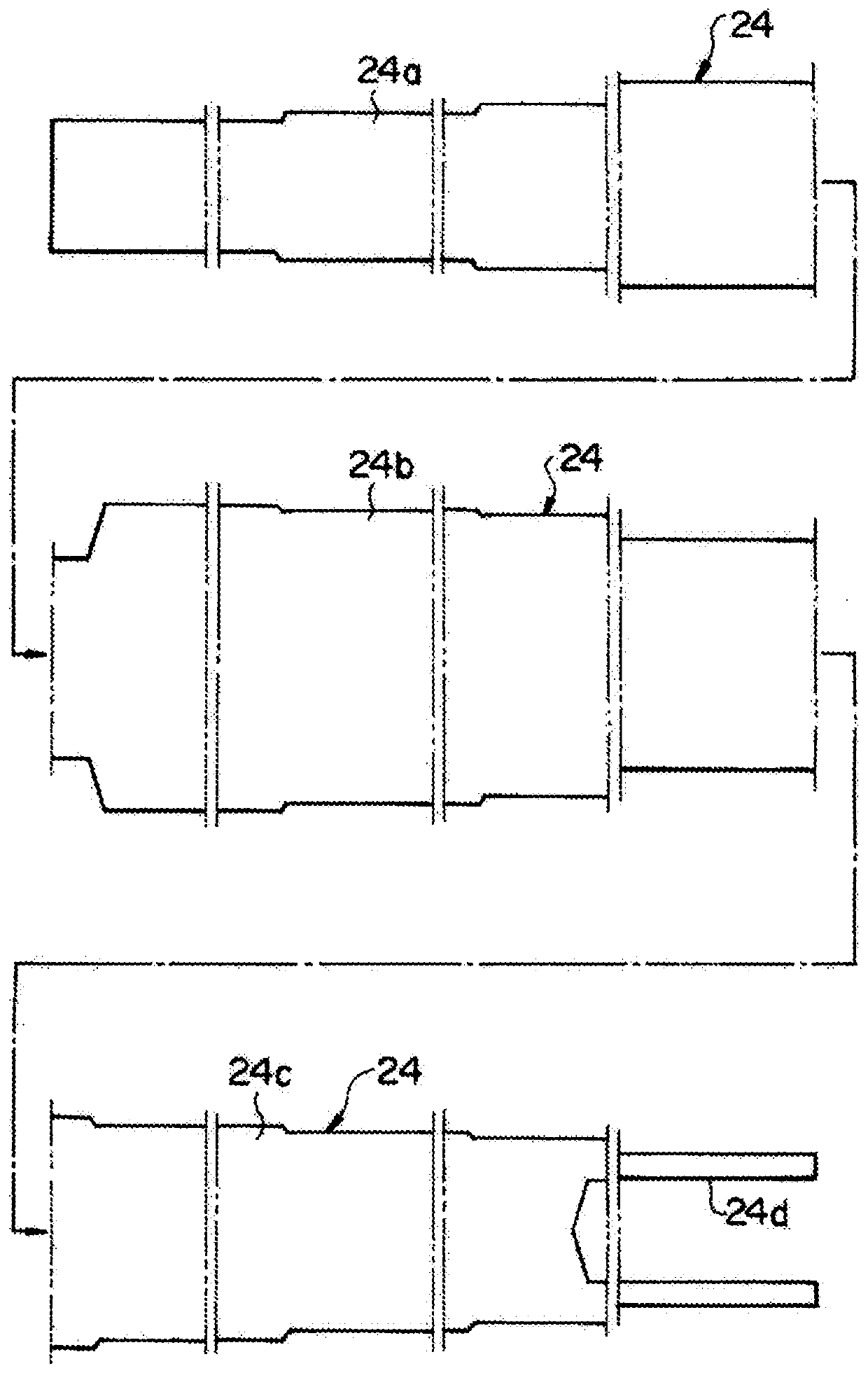

[0018] exist figure 1 Among them, reference numeral 11 is a vulcanized pneumatic radial tire mounted on a large construction vehicle. This tire 11 has a pair of bead portions 13 in which annular beads 12 are respectively embedded, a pair of sidewall portions 14 extending generally radially outward from the bead portions 13 , and the sidewall portions 14 described above. A substantially cylindrical tread portion 15 in which radially outer ends are connected to each other. Further, the tire 11 is reinforced with a ring-shaped carcass layer 18 extending from one bead portion 13 to the other bead portion 13 . Both ends in the width direction of the carcass layer 18 are folded back around the beads 12 . A belt layer 19 is disposed radially outside the carcass layer 18 . Further, a tread 20 is arranged radially outside the belt layer 19 , and grooves having a wide width are formed on the outer surface (contact surface) of the tread 20 . Here, the aforementioned tread 20 is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com