Wire harness

A wire harness and wire technology, which is applied in the field of wire installation exterior components, can solve problems such as complex shapes and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] {implementation method}

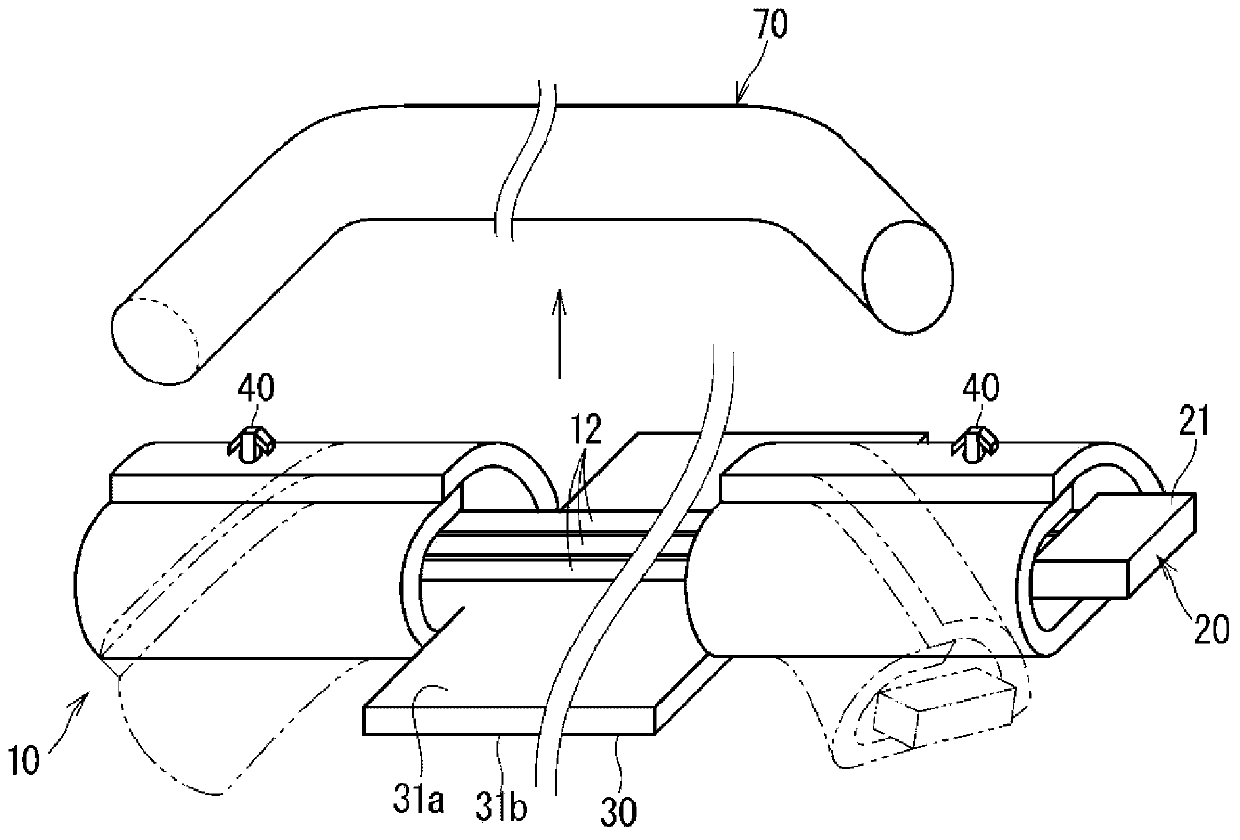

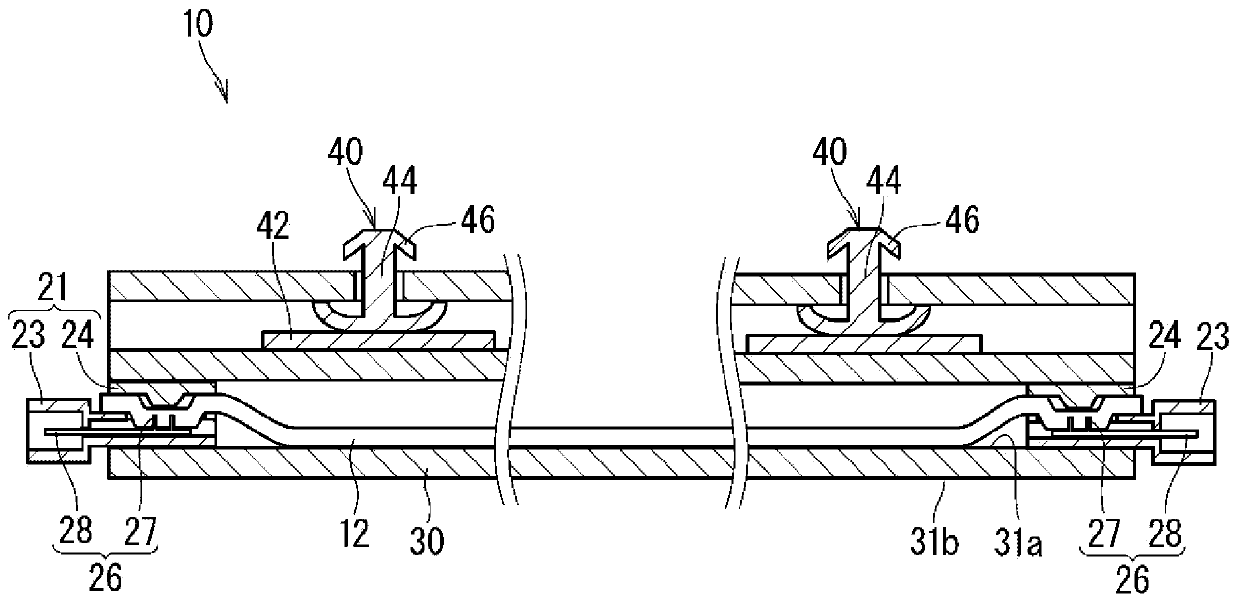

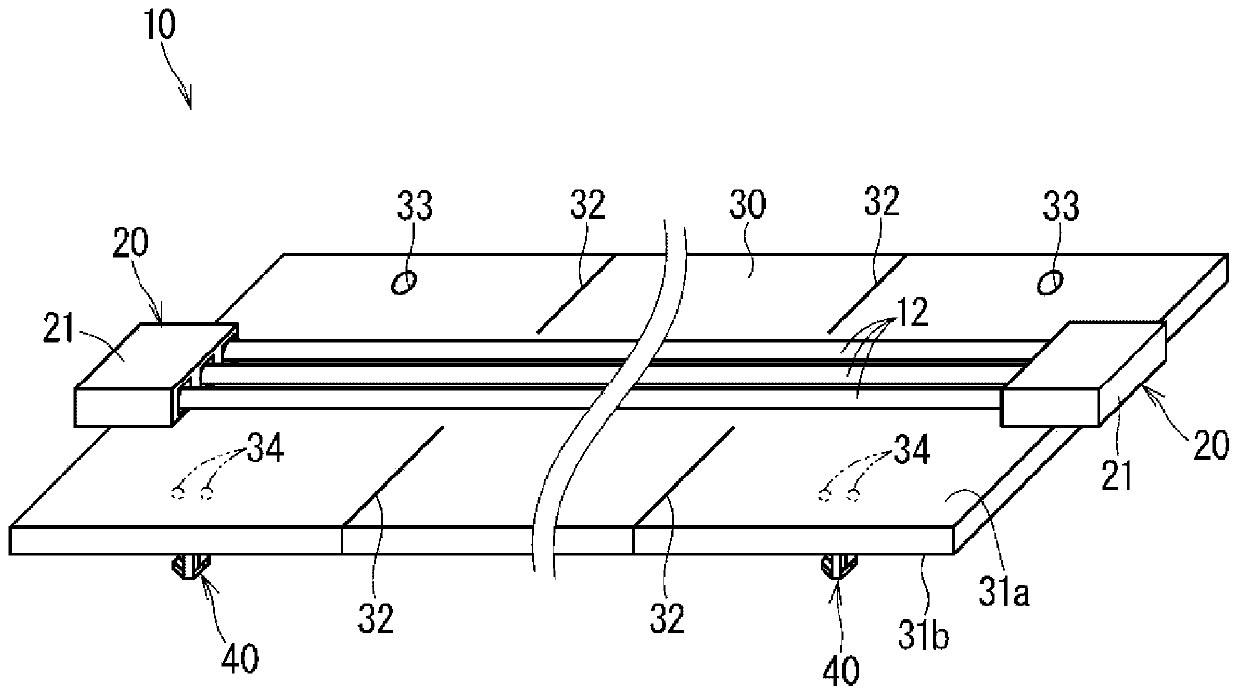

[0033] Hereinafter, the wire harness according to the embodiment will be described. figure 1 It is a perspective view which shows the wire harness 10 which concerns on embodiment. figure 2 It is a schematic cross-sectional view showing the wire harness 10 according to the embodiment. image 3 It is a perspective view showing the state before the exterior member 30 is rolled up. Figure 4 It is a bottom view showing the state before the exterior member 30 is rolled up.

[0034] The wire harness 10 is used as wiring for electrically connecting various electric devices mounted on a vehicle or the like. Here, the wire harness 10 will be described as a wire harness that is wired around an instrument panel in a vehicle, for example. Of course, the place where the wire harness 10 is routed in the vehicle is not limited to the above-mentioned places, and may be routed around the ceiling, the door, and the like. Specifically, the wire harness 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com