Hydraulic rolling and spreading machine for geotechnical cloth

A technology of geotextiles and roll paving machines, which is applied in the direction of roads, road repairs, roads, etc., can solve the problems of long exposure time of the base surface, affecting the quality of base care, and high labor intensity, so as to save manpower, save labor, and reduce work. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

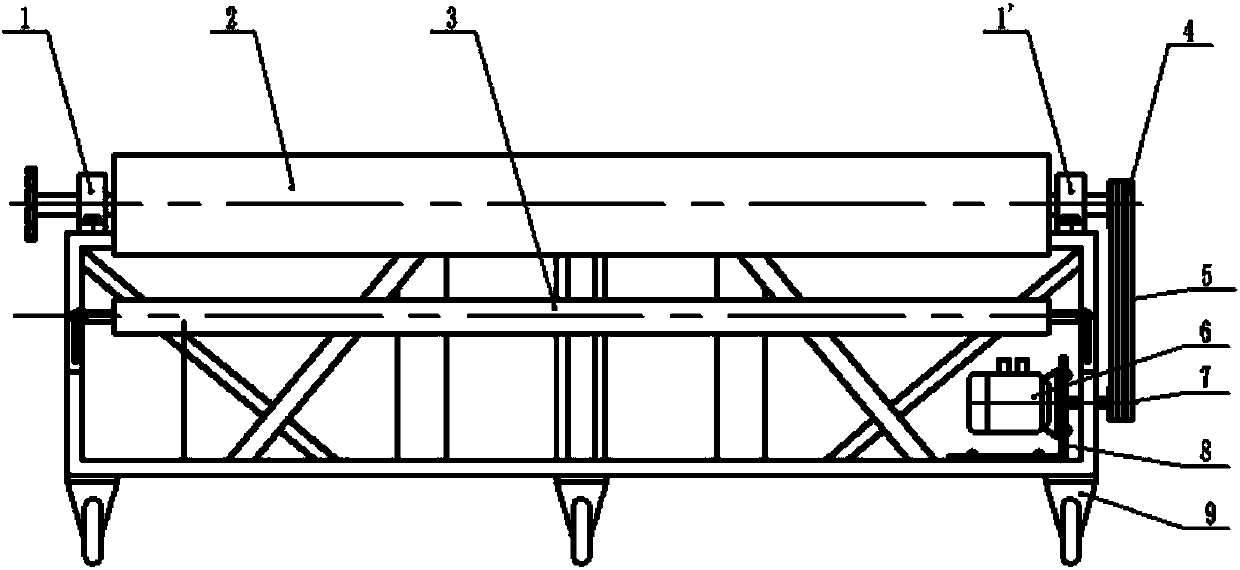

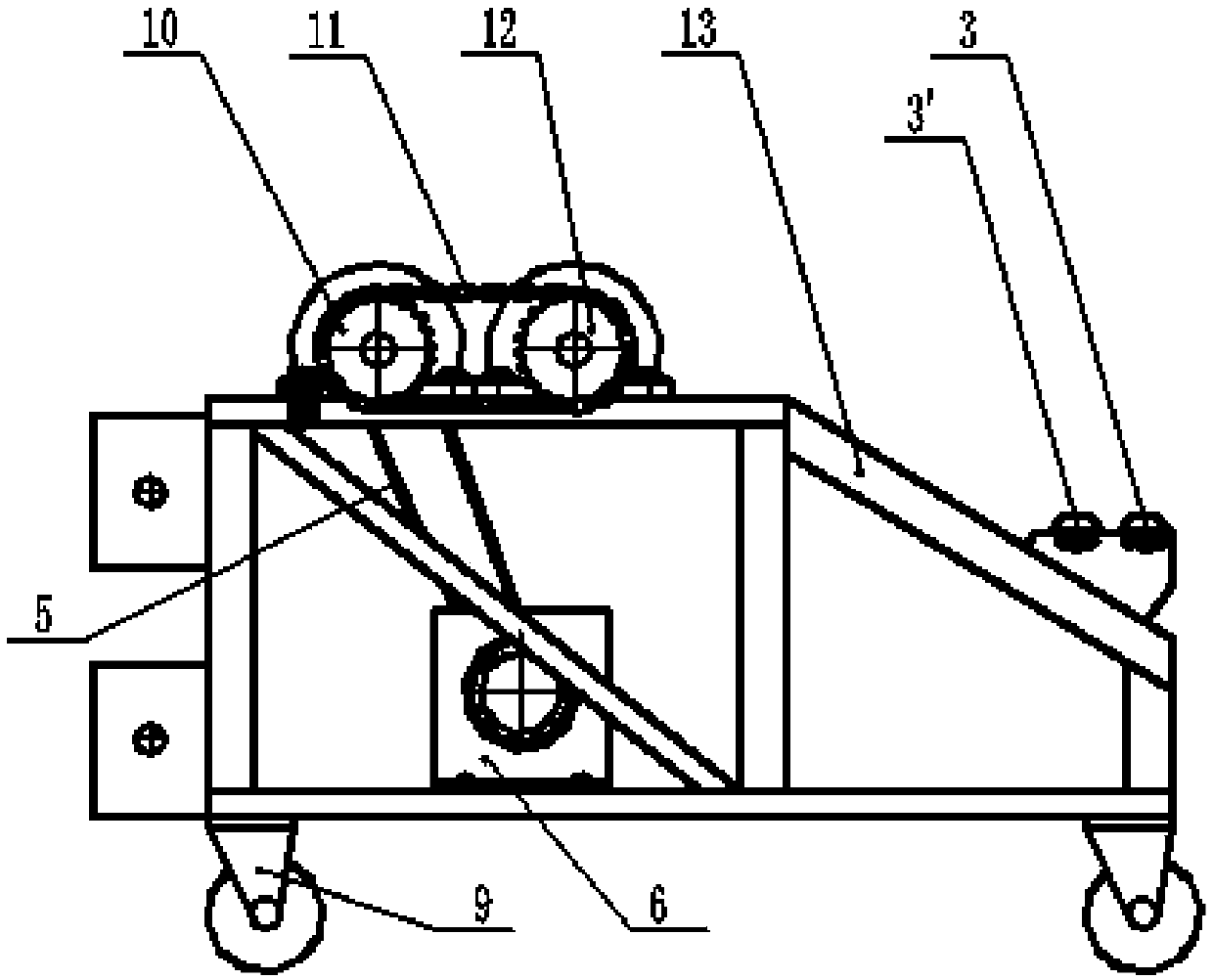

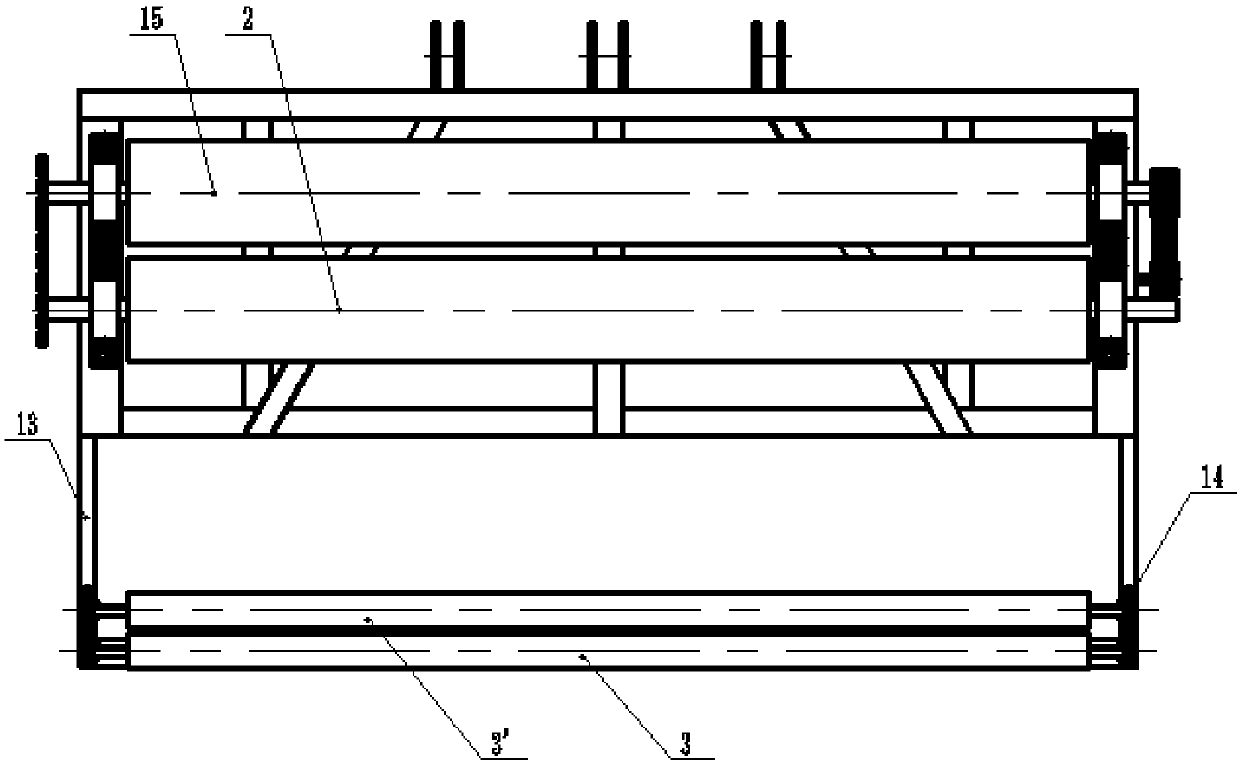

[0017] figure 1 --4, 1, left roller bearing seat; 1', right roller bearing seat; 2, driven reel; 3, front idler roller; 3', idler roller; 4, driven pulley; 5, V-belt; 6 , hydraulic motor; 7, driving pulley; 8, hydraulic motor bracket; 9, universal wheel; 10, driving reel sprocket; 11, chain; 12, driven reel sprocket; 13, frame; 14, fixed roller shaft board; 15, driving reel; 16, geotextile core PVC pipe.

[0018] Depend on figure 1 --4 It can be seen that a hydraulic geotextile roll paving machine is composed of a frame 13, a hydraulic motor 6, a transmission device, a driving reel 15 and a driven reel 2, supporting rollers and universal wheels 9, and the whole device The boom of the loader is connected with pins, and the above-mentioned hydraulic motor 6 is connected with the hydraulic pump of the loader through a hydraulic pipeline; this device uses the hydraulic pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com