The Secondary Battery And Top Insulator For Secondary Battery

A technology of secondary batteries and insulators, which is applied in the direction of secondary batteries, secondary battery manufacturing, battery pack components, etc., can solve problems such as production decline, short circuit, and increase in manufacturing costs, so as to increase production, reduce manufacturing costs, and suppress The effect of dust

Active Publication Date: 2019-08-06

LG ENERGY SOLUTION LTD

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, thermoplastic resins have a rather low melting point of 200°C to 250°C

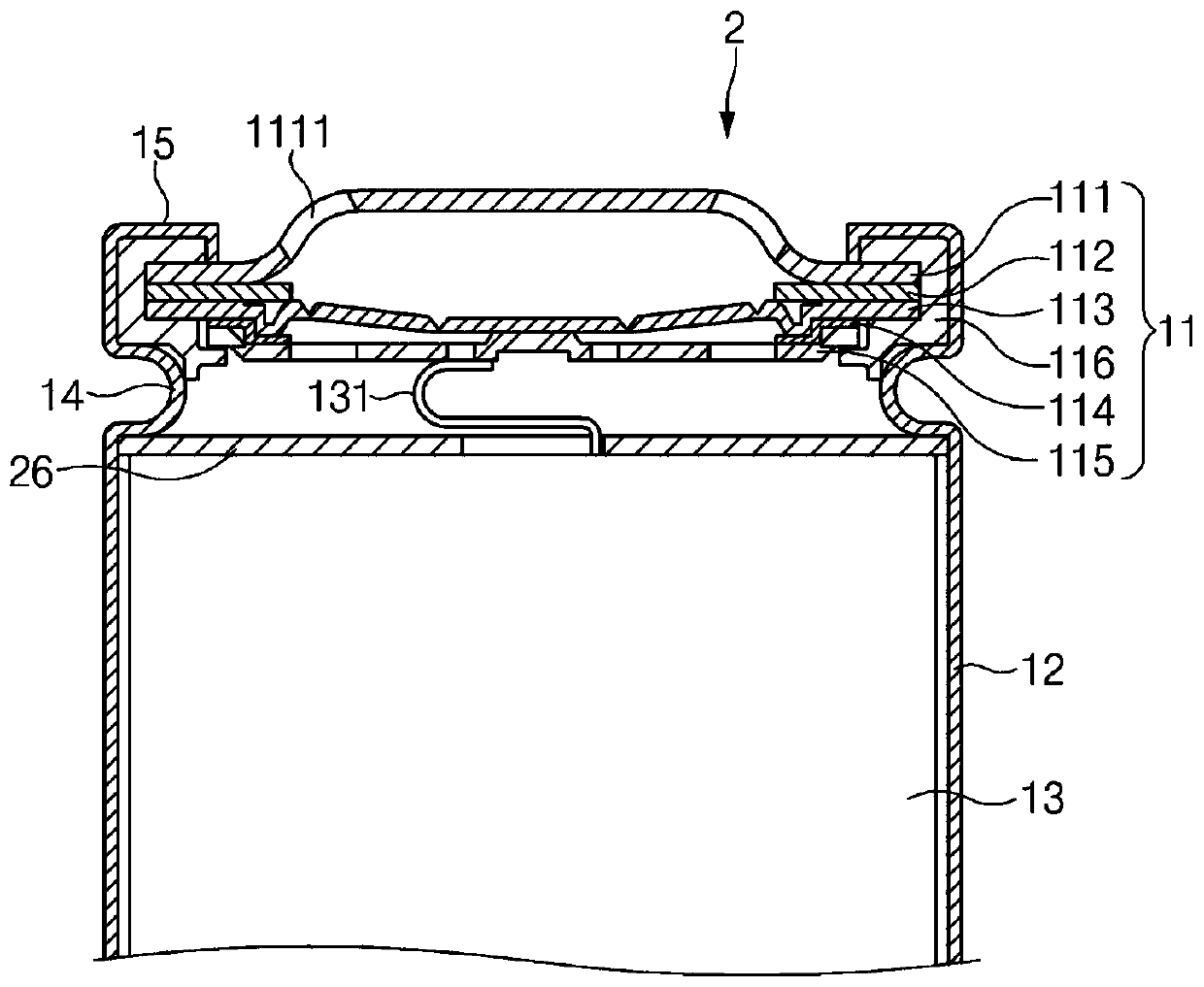

In addition, there is a problem that when the internal temperature of the secondary battery 2 rises sharply above 250° C., the top insulator 26 melts to cause a short circuit.

However, the melting point of phenol itself is very low at a temperature of 40°C, and even if it is applied to a glass fiber fab

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Login to View More

Abstract

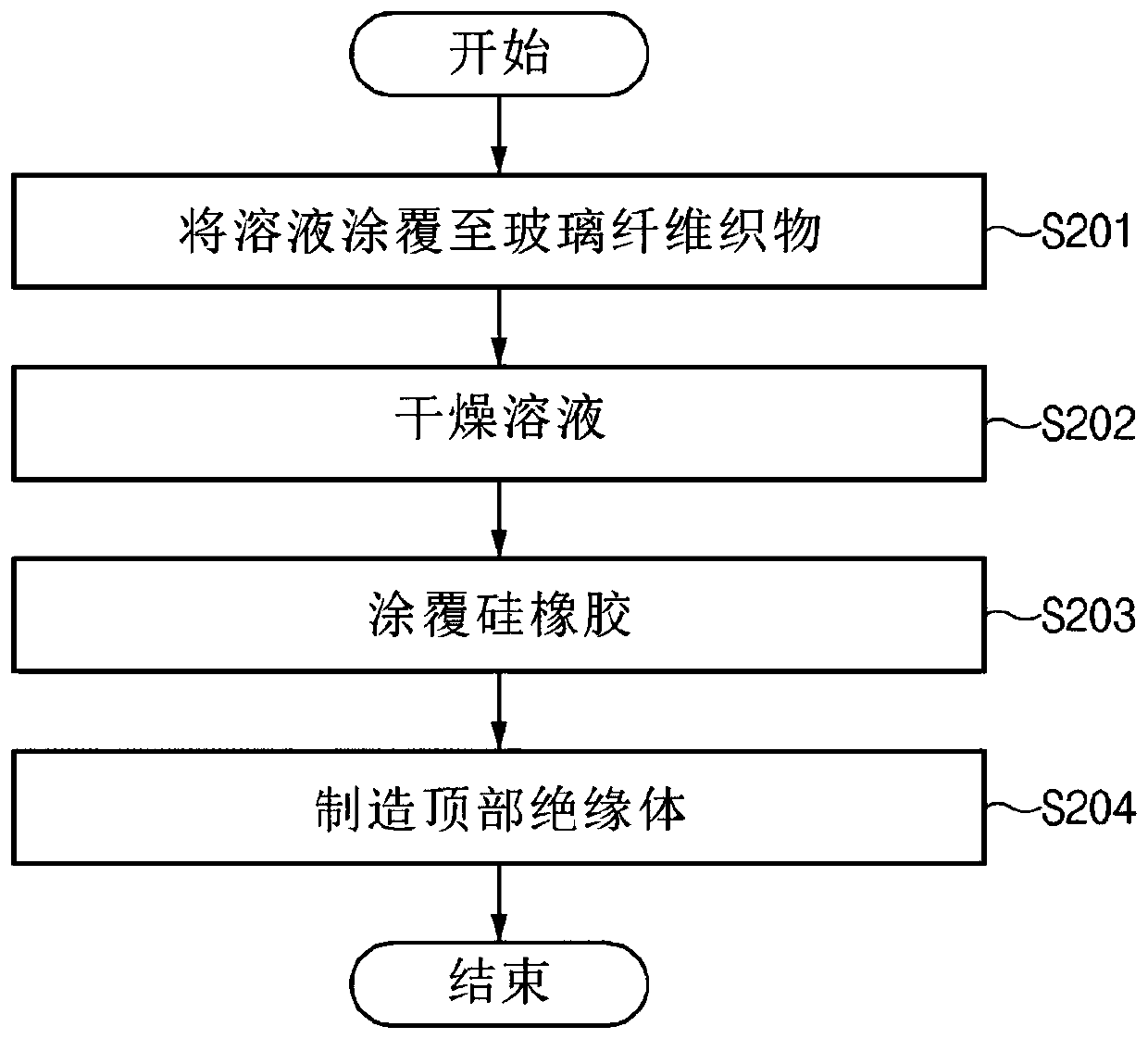

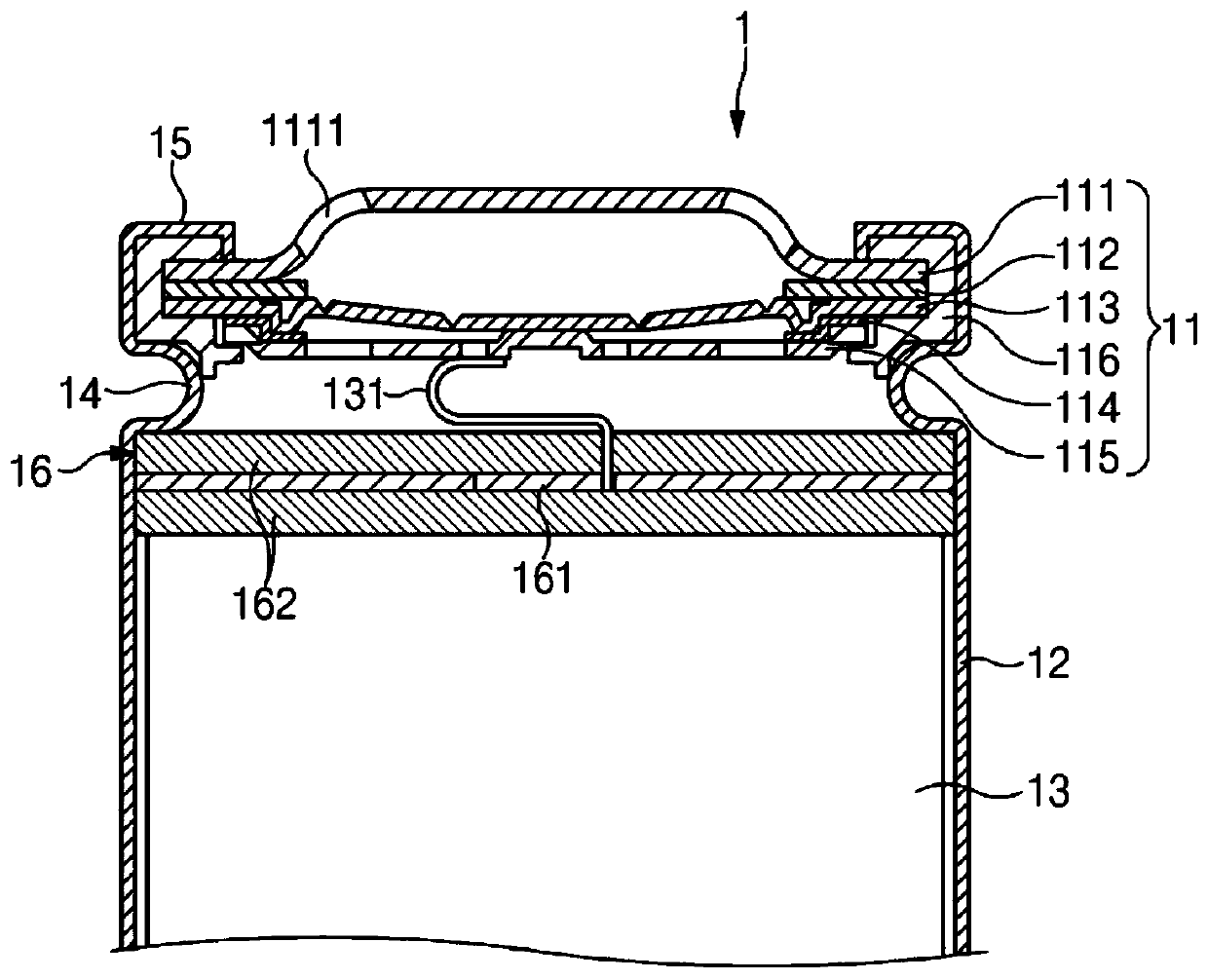

An insulation plate for a rechargeable battery, according to one embodiment of the present invention, in order to solve said problem, is an insulation plate which is inserted in a case of a rechargeable battery, and which comprises: a glass fiber formed by intersecting weft and warp glass fiber yarns; and silicone rubber coated on at least one surface of the glass fiber.

Description

[0001] Cross References to Related Applications [0002] This application claims the benefit of Korean Patent Application No. 10-2018-0010900 filed on January 29, 2018 and Korean Patent Application No. 10-2018-0125529 filed on October 19, 2018, which are incorporated by reference The patent application is hereby incorporated in its entirety. technical field [0003] The present invention relates to a top insulator for a secondary battery and a manufacturing method thereof, and more particularly, to a top insulator which is improved in characteristics such as heat resistance and chemical resistance and which is used in a punching process. A secondary battery that suppresses generation of dust, and a top insulator for the secondary battery. Background technique [0004] Generally, secondary batteries include nickel-cadmium batteries, nickel-hydrogen batteries, lithium-ion batteries, and lithium-ion polymer batteries. Such secondary batteries are being used in small products ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M2/34H01M10/0525H01M10/058H01M50/593

CPCH01M10/0525H01M10/058H01M50/593H01M10/04Y02E60/10Y02P70/50

Inventor 李炳九金度均郑湘锡申亢秀

Owner LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com