Rectangular pyramid coiling drum applied to cold-rolled strip steel coiling machine

A technology of cold-rolled strip steel and quadrangular pyramid, applied in the field of cold-rolled strip steel reels, can solve the problems of inconvenient coiling and unloading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

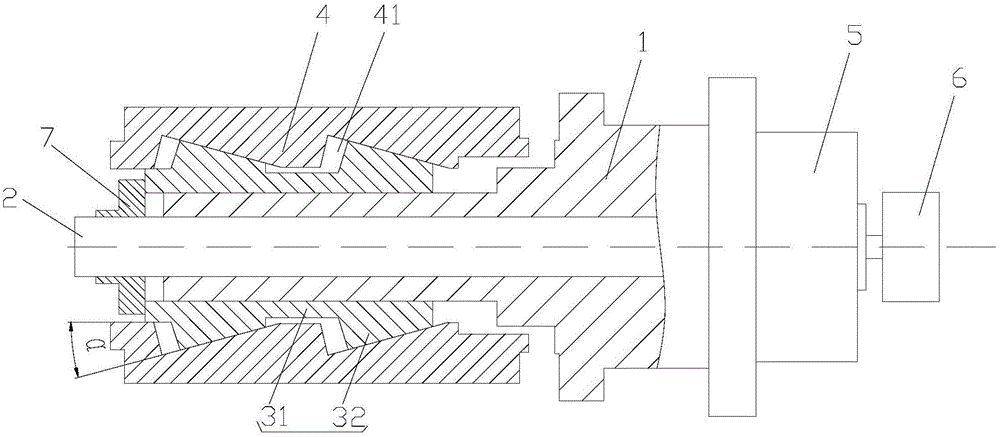

[0011] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a quadrangular pyramid reel applied to a cold-rolled strip coiler proposed by the present invention.

[0012] refer to figure 1 , a quadrangular pyramid reel applied to a cold-rolled strip coiler proposed by the present invention, including a reel inner shaft 1, a pull rod 2, four expansion and contraction blocks 3, four reel sector plates 4, and an expansion and contraction oil cylinder 5. The rotating head 6 and the crosshead positioning member 7, the reel inner shaft 1 and the rotating head 6 are arranged coaxially, one end of the reel inner shaft 1 is driven to rotate by the rotating head 6, and the cross section of the other end of the reel inner shaft 1 is square, The pull rod 2 is set through the inner shaft 1 of the reel, and the pull rod 2 is connected with the expansion and contraction cylinder 5 at one end of the rotating head 6 and stretches along the axial direction of the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com