Fabricated self-reset U-shaped metal damper

A metal damper and self-resetting technology, which is applied in building types, protected buildings/shelters, buildings, etc., can solve the problem of lack of self-resetting ability, energy-consuming components, structural stress and use functions that are difficult to repair and self-resetting Small capacity and other problems, to achieve the effect of convenient and efficient installation and disassembly, simple structure and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

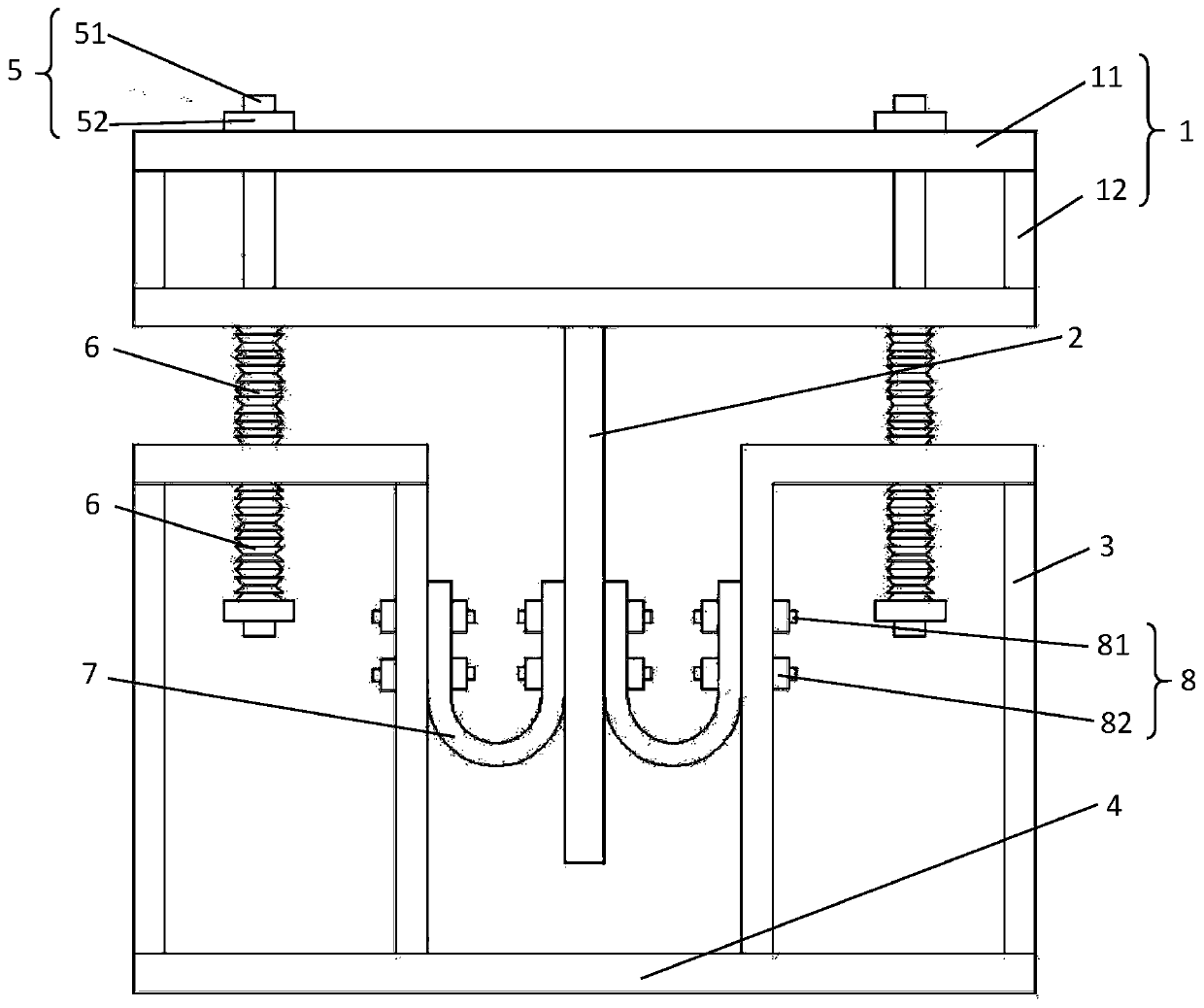

[0071] See attached figure 1 , the embodiment of the present invention discloses an assembled self-resetting U-shaped metal damper, including: a steel plate composite member 1, a piston member 2, a box-shaped member 3, a bottom plate 4, a fastener 5, an elastic member 6 and a U-shaped plate 7;

[0072] The steel plate composite member 1 includes a flange plate 11 and a web 12; two flange plates 11 are arranged in parallel up and down; a plurality of web plates 12 are fixed between the two flange plates 11;

[0073] The piston member 2 is fixedly connected to the center of the bottom surface of the lower flange plate 11;

[0074] The box-shaped member 3 is a box-shaped structure with two ends open or closed, and a plurality of box-shaped members 3 are arranged around the piston member 2;

[0075] The bottom plate 4 serves as the common bottom of a plurality of box-shaped components 3;

[0076] Fastener 5 fits through the top plate of two flange plates 11 and box-shaped membe...

Embodiment 2

[0091] The difference between this embodiment and Embodiment 1 is that the piston member 2 is a triangular box-shaped structure composed of three steel plates, the number of box-shaped members 3 and U-shaped plates 7 are three, and the box-shaped members 3 are respectively located in three On the outside of each steel plate, U-shaped plates 7 are respectively located between each steel plate and the box-shaped member 3 .

[0092] Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0094] The difference between this embodiment and Embodiment 1 is that the piston member 2 is a rectangular box-shaped structure composed of four steel plates, the number of box-shaped members 3 and U-shaped plates 7 are four, and the box-shaped members 3 are respectively located on four On the outside of each steel plate, U-shaped plates 7 are respectively located between each steel plate and the box-shaped member 3 .

[0095] Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com