Novel fluid supercharger

A turbocharger and fluid technology, which is applied in the direction of fluid pressure converters, mechanical equipment, etc., can solve the problems of low working efficiency and energy consumption of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

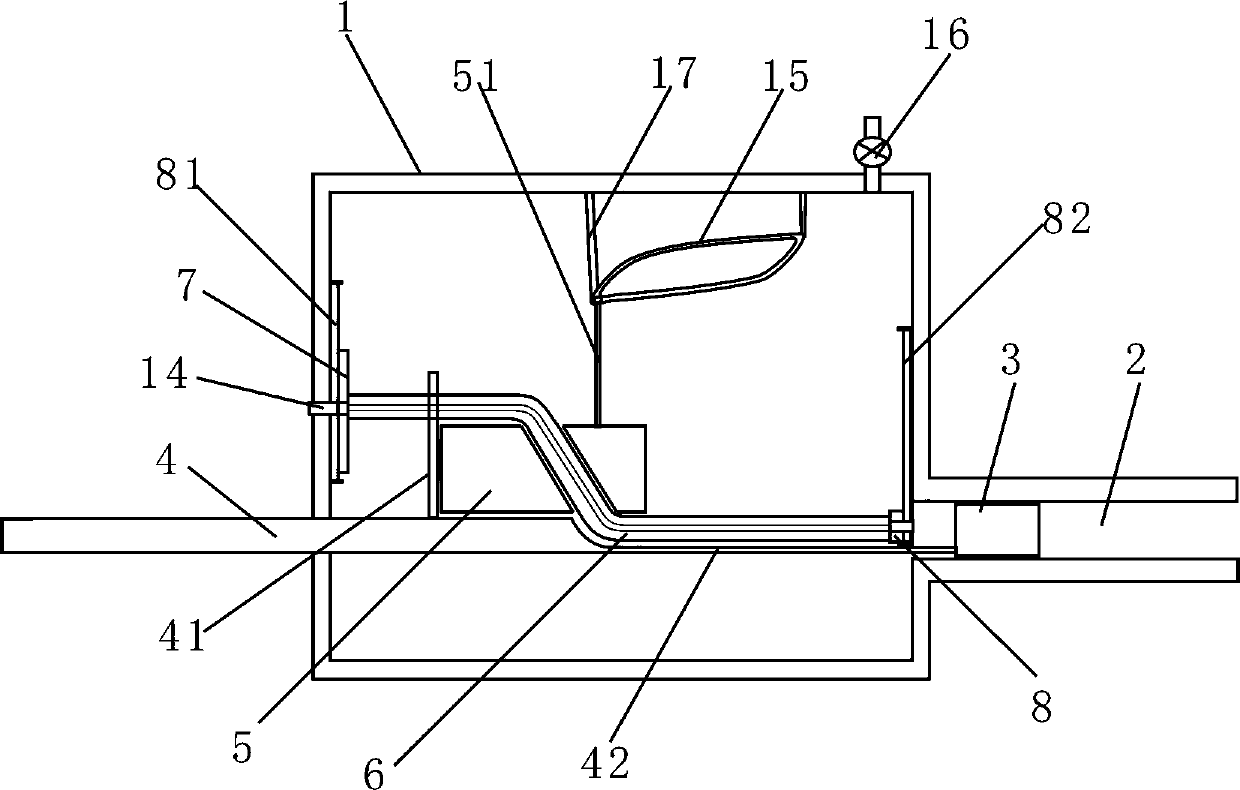

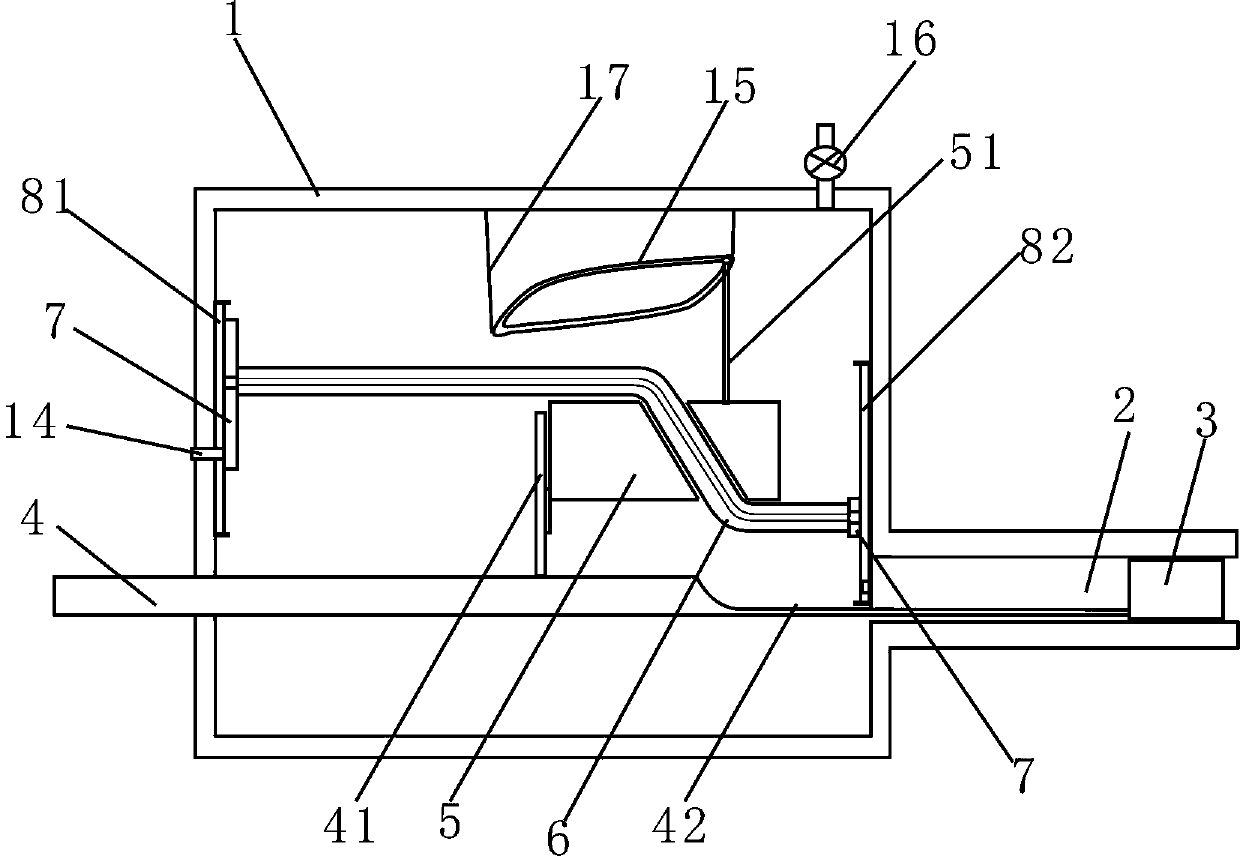

[0016] Embodiment: a kind of novel fluid booster, as figure 1 , figure 2 As shown, it is composed of a high-pressure fluid tank 1, a cylinder 2, a piston 3, a piston rod 4, a moving slider 5 and a flexible rod 6. One end of the high-pressure fluid tank 1 communicates with the left side of the cylinder 2. A piston 3 is installed in the cylinder 2. The piston 2 is connected to the piston rod 4. The piston rod 4 runs through the high-pressure fluid tank 1 and is connected to the piston in the cylinder 2. The end of the piston rod 4 is located at the high-pressure Outside the fluid tank 1, the end of the piston rod 4 is connected to an engine or a telescopic power mechanism to drive the piston rod to do telescopic movement. The high-pressure fluid tank 1 is provided with an output gas port 16 with a valve for outputting high-pressure fluid to the outside.

[0017] The moving slider 5 is installed in the high-pressure fluid tank 1, and the left end is connected with the slider c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com