Supporting mold safety monitoring device and monitoring method

A technology for safety monitoring and support rods, applied to measuring devices, instruments, etc., can solve problems such as fastener failure, effective monitoring, and light obstruction of formwork brackets, and achieve the effect of simple wiring and simple and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

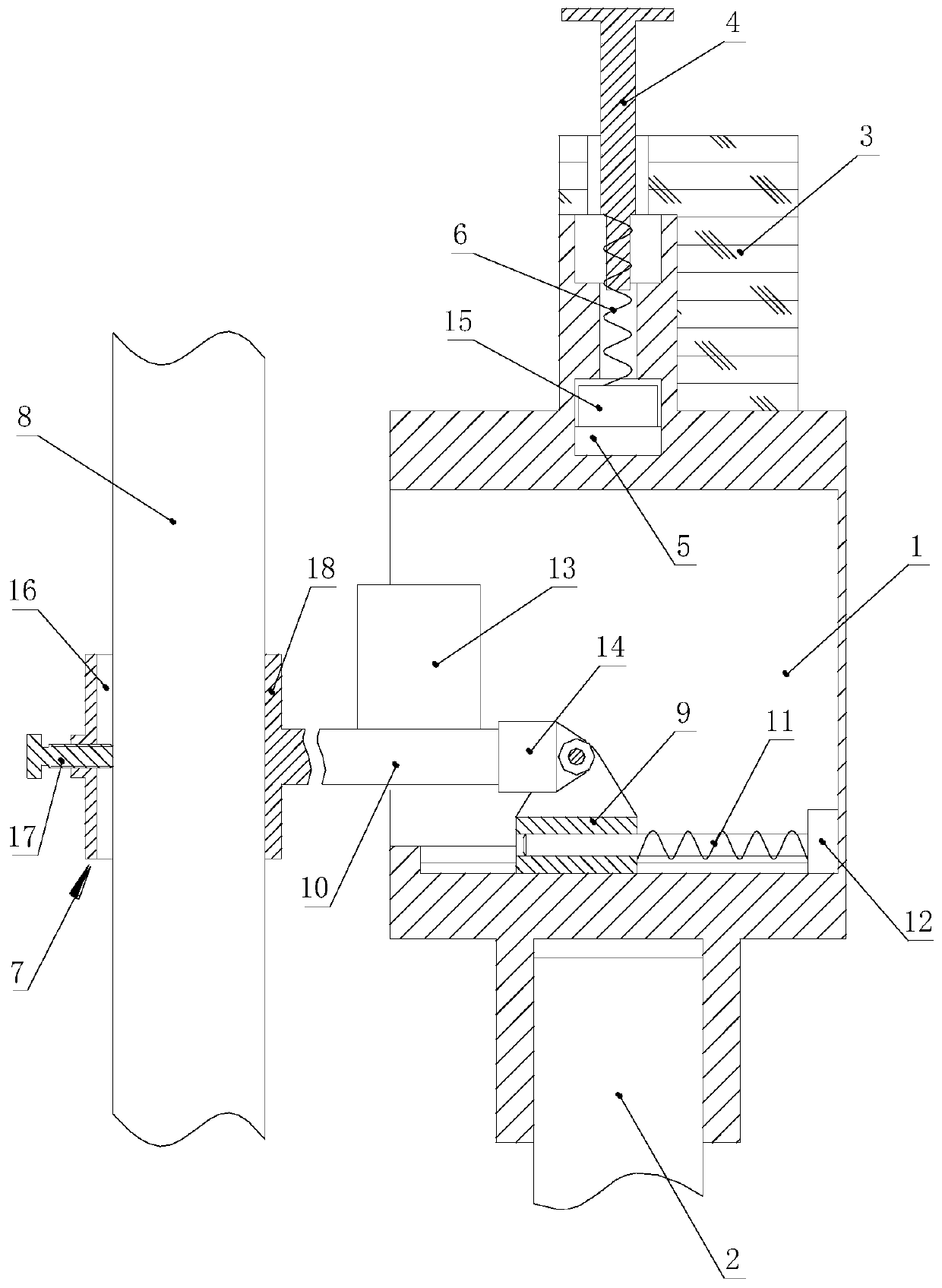

[0031] A formwork safety monitoring device, comprising a main body 1, a support rod 2 is provided at the lower part of the main body 1, and the support rod 2 is used for installing and fixing the main body 1 of the monitoring device. The lower end of the support rod 2 is used for fixed connection with the foundation of the form support, specifically, the main body 1 is installed in the form support through the support rod 2, and the installation base is located on the foundation erected by the form support. The upper end of the main body 1 is provided with a displacement sensor 3, and the displacement sensor 3 includes a sliding rod 4. It should be understood that the displacement sensor 3 can monitor the position of the sliding rod 4, that is, the monitoring contact part of the displacement sensor 3 is the sliding rod 4. In this embodiment, the displacement sensor 3 adopts a Hall sensor / magnetic sensor, so that the monitoring channels of the sliding rod 4 and the displacement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com