Cyclone separation device

A technology of a cyclone separation device and a mounting body, which is applied in suction filters, cleaning equipment, vacuum cleaners, etc., can solve problems such as affecting the gas-solid separation efficiency of the cyclone separation device, easily blocking the filter screen cover, and large filter pressure of the filter element.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content, structural features, achieved goals and effects of the invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

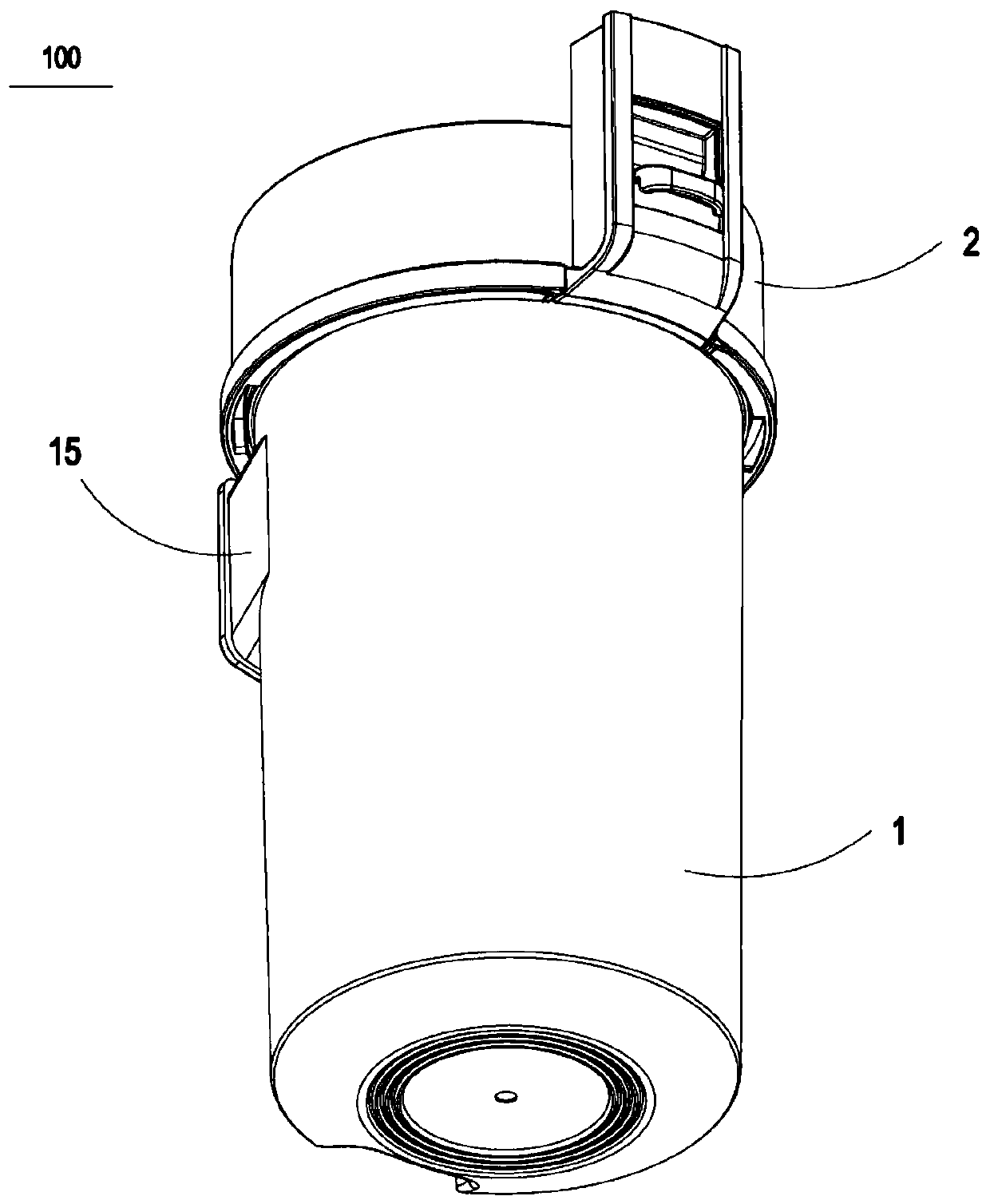

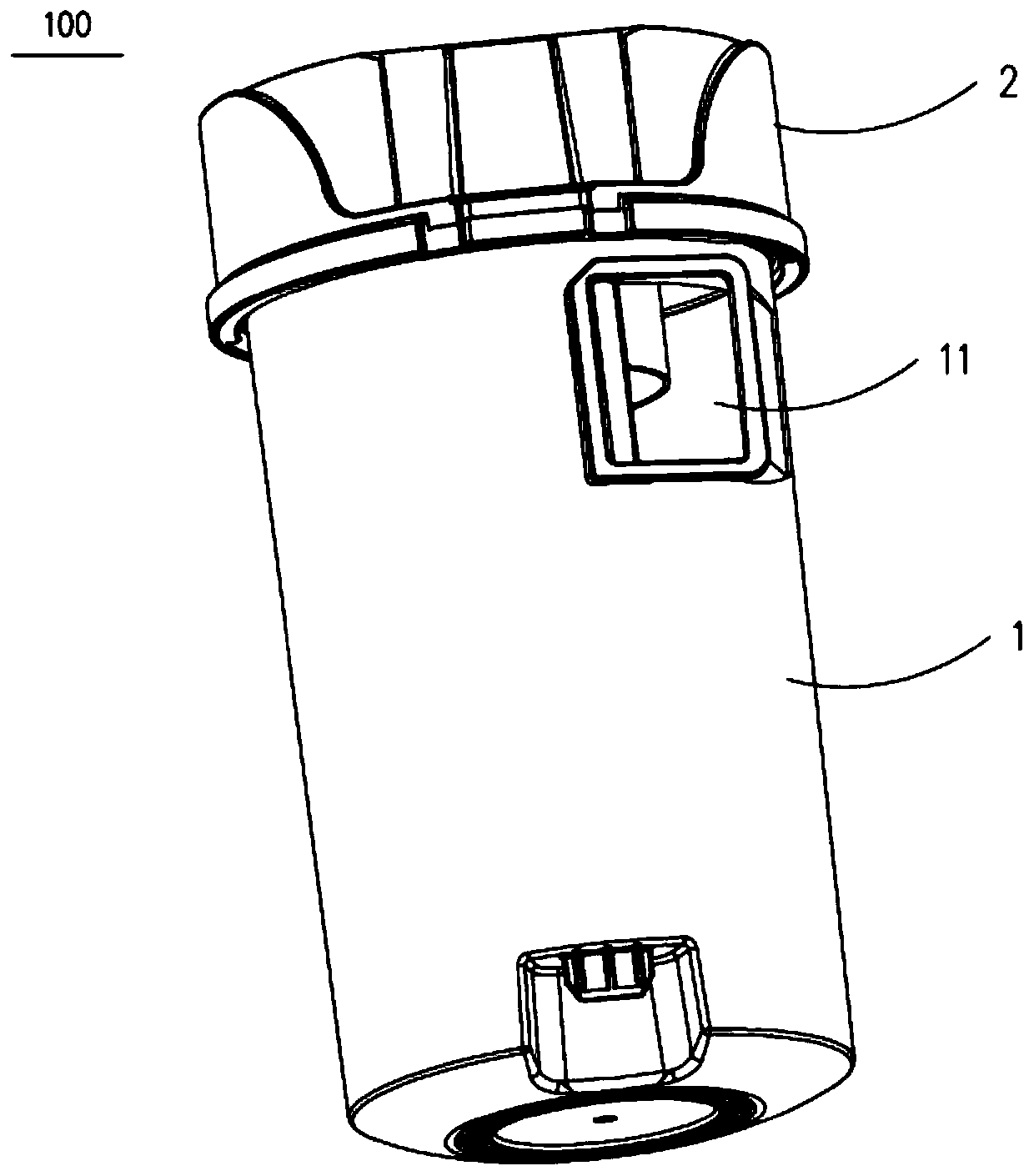

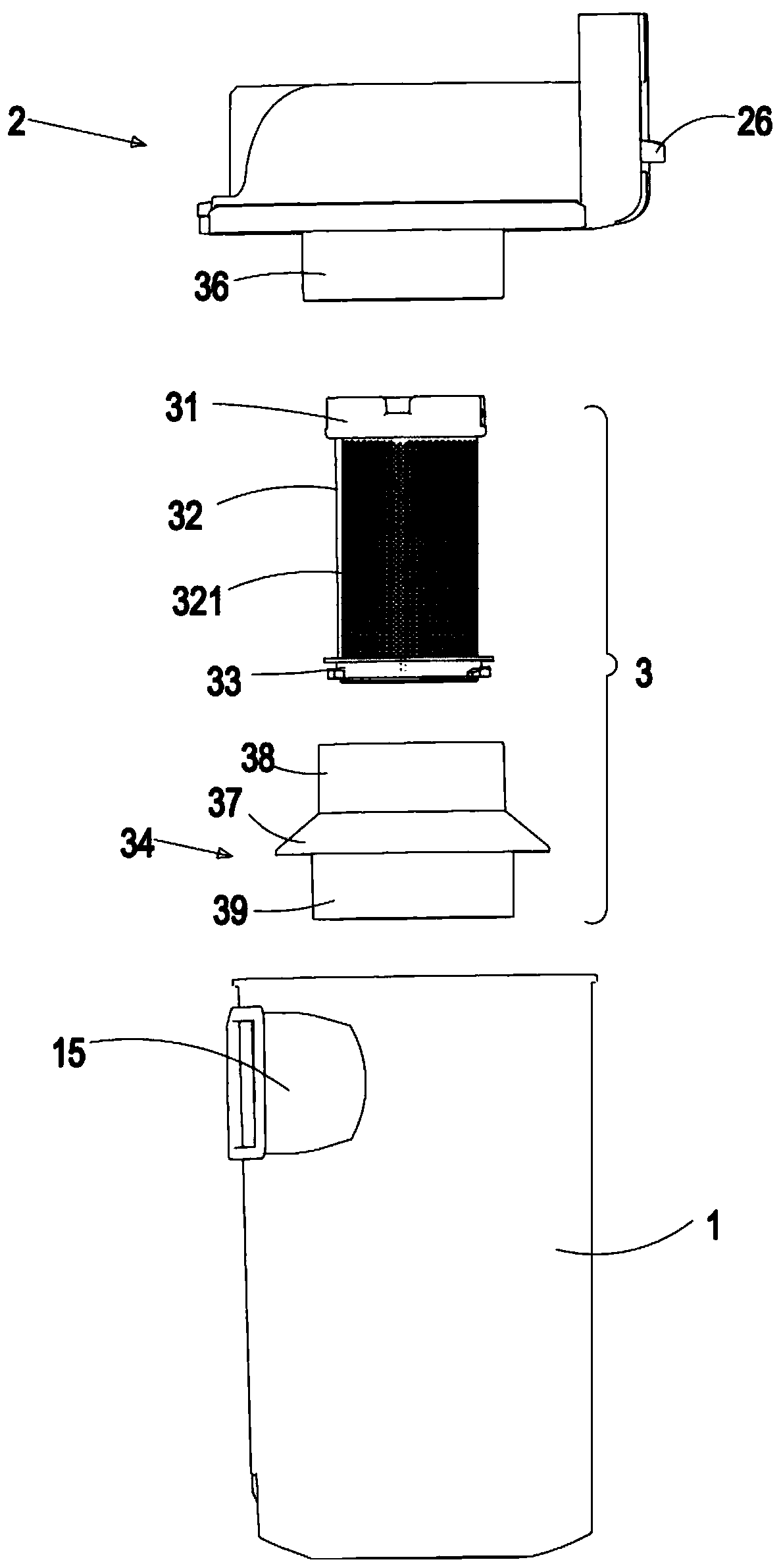

[0034] like Figure 1-3 As shown, the cyclone separation device 100 according to the embodiment of the present invention includes: a dust cup 1 , a top cover assembly 2 and a filter element assembly 3 . The filter element assembly 3 includes an upper mounting body 31 , a metal filter screen cover 32 with several filtering holes 321 , a lower mounting body 33 and a lower base 34 . The dust cup 1 is a structure with a closed bottom and an open top. The outside of the dust cup 1 is provided with a spiral air inlet 15 connected to the inside of the dust cup 1 , and the side wall of the dust cup 1 is provided with an air inlet 11 connected to the spiral air passage 15 . Due to the existence of the spiral air duct 15, the dust-laden airflow entering t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com