A construction method for dewatering system for silty soil with high moisture content

A technology with high water content and construction method, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of non-reusable, non-removable, long processing time, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Taking the precipitation consolidation of a highway subgrade filling as an example, the subgrade filling of this project is mainly silty clay, and the empirical value of the permeability coefficient of the soil is 5×10 -7 m / s, due to the atmospheric precipitation and artificial mining here, groundwater flows from northwest to southeast, resulting in the water content of silty clay in the foundation (ω 1 ) reaches 25% and above, which does not meet the requirements as roadbed filler, and the moisture content will be reduced to 12% to 15% (ω 2 ), so that the silty clay can meet the requirements of this expressway roadbed filler.

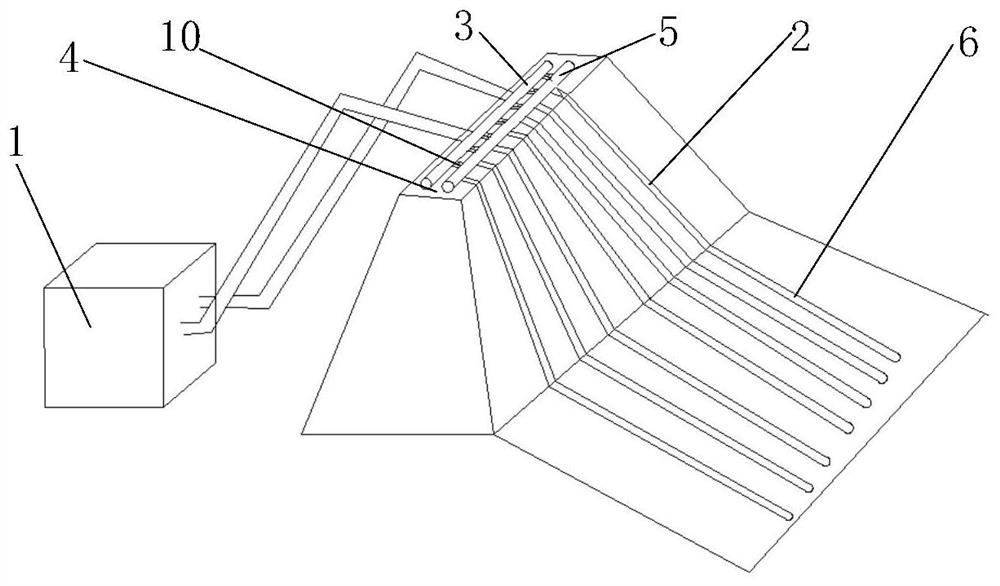

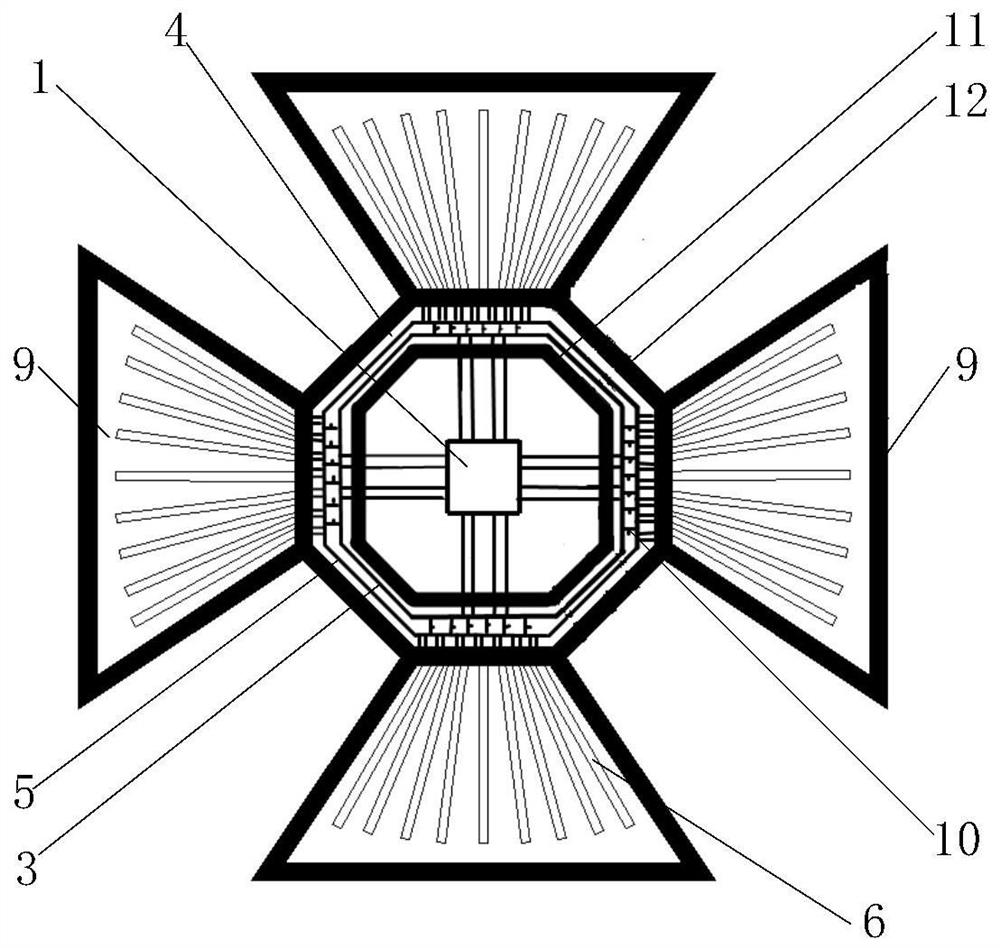

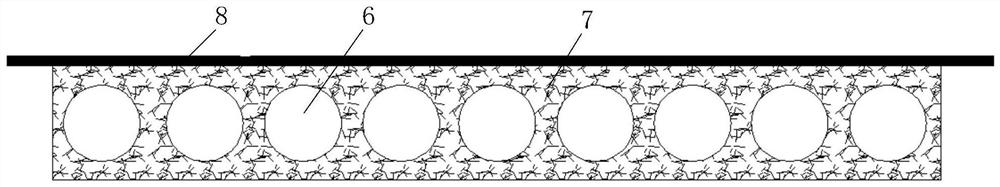

[0098] Such as figure 2 As shown, construct a drainage system for silty soil with high water content, plan a 22m long and 22m wide square open space around the expressway construction project, remove sundries and weeds on the surface, The center first builds the regular octagonal inner wall 11 of the sump 4, the vacuum pump 1 is placed inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com